With the continuous development of economy and the progress of science and technology, CNC turning service plays an increasingly important role in industrial production. However, CNC turning service price is influenced by various factors. This article will discuss the topic of CNC turning service price.

Material Selection

The choice of raw material has a direct impact on CNC turning service price, as different materials have different costs, availability and machining characteristics. For example, high performance alloys may be more expensive than common metals. In addition, the availability of a particular material can affect its pricing.

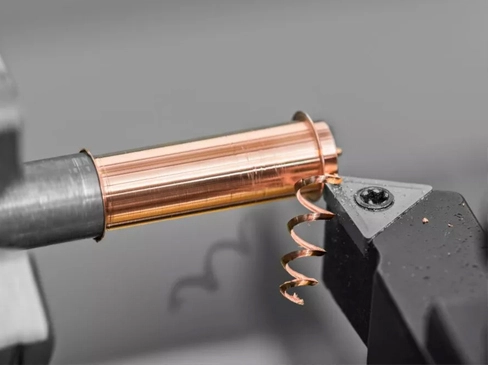

Complexity of Design

The complexity of a machined part or assembly plays a critical role in CNC turning service price. Parts with complex features, tight tolerances, and intricate geometries often require more advanced machining techniques, specialized tooling, and longer machining times. These factors increase the CNC turning service price due to the higher level of precision and expertise required to produce such complex components.

Production Volumes and Lot Sizes

Production volume and batch size directly affect CNC turning service price. Economies of scale come into play when production volumes are high. The price per part tends to decrease as production volume increases. However, it is important to consider the balance between production volume and setup time. Smaller production runs may have a higher price per part due to increased setup time, whereas larger production runs may reduce setup time and lower the cost per part.

Scrap and Rework

Scrap and rework is an important consideration in CNC turning service price. Material waste due to errors or specification deviations can add significantly to the cost. Minimizing scrap through effective quality control measures and precision machining techniques can help reduce material waste and rework requirements, ultimately reducing the overall CNC turning service price.

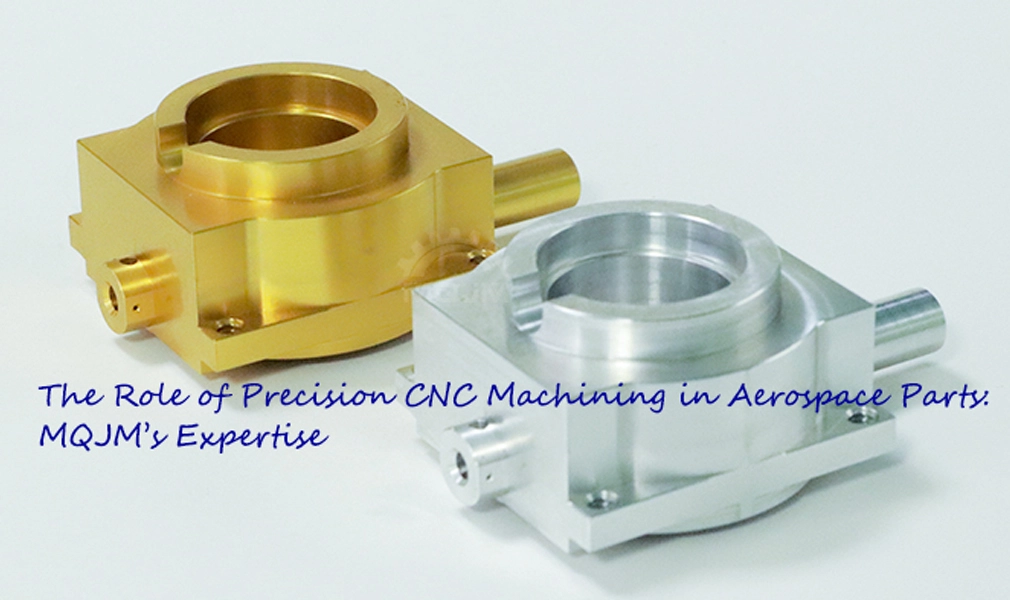

Shenzhen Mingqiang Precision Hardware Products Co., LTD., is a professional CNC machining manufacturer. MQJM specialises in CNC turning and milling and has more than 13 years of manufacturing experience. We keep adopting advanced production facilities to improve efficiency and ensure high and stable quality, and further reduce the production cost. The objective is to create reliable, viable and affordable product, CNC machining parts and fast sample service for every industry. If you are looking for CNC turning service, we will be your trustworthy choice.