A Canadian customer inquired if we could provide assembly services. We replied that, in addition to CNC machining parts, we also offer assembly services.

Here are some examples of our custom assembly services:

Case 1: Lighting Fixtures

We have been working with an Australian company for six years, and their main products are various lighting fixtures, such as downlights, floor lamps, and outdoor ground lights. In August of this year, the customer placed an order for 2,000 sets of new lighting products, requesting us to assemble them as we have done in the past. These lights are made from several custom aluminum parts, making them lightweight. For every new project, we produce 1-5 trial units to test the dimensions, threading, and usability. For this CNC lighting project, we trial-produced five sets and verified that each part's dimensions matched the customer’s drawings, the threading was smooth, and assembly proceeded without any issues. Below is a picture of our team assembling this custom CNC lighting product.

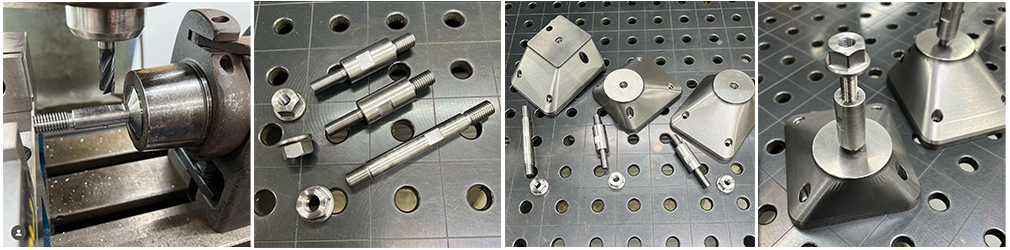

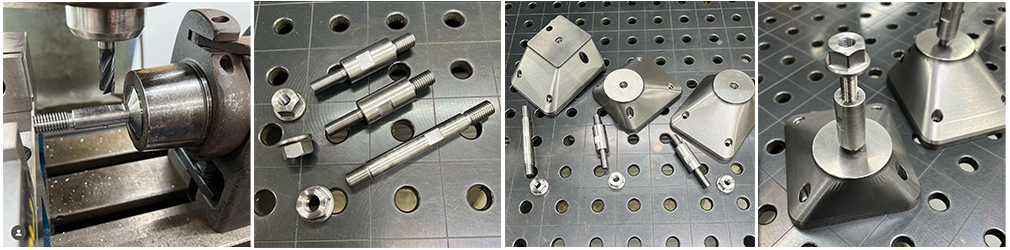

Case 2: Specialized Industrial Products

In May of this year, a U.S. customer reached out for an online CNC quote. They were working on a new project and required CNC turning, CNC milling, assembly, and custom packaging services. The customer shared their overall concept and design with us and sent their matching parts for reference. After evaluating the project, our engineering team immediately began production. We maintained strict control over the tolerance requirements between the CNC-machined parts and the matching components to meet the customer’s precision standards. The following month, our packaging staff began assembling and packing the products, ensuring 100% quality inspection before assembly. The customer was highly satisfied with our CNC machining and assembly services.

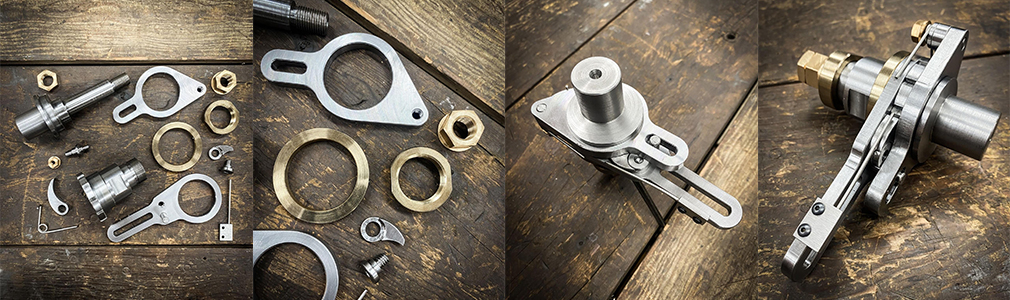

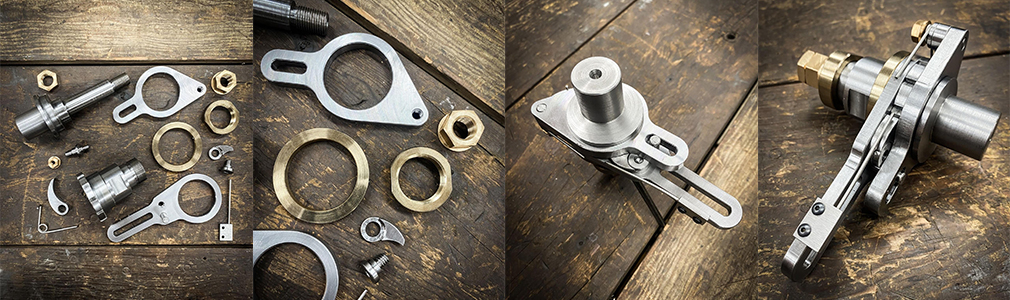

Case 3: Tattoo Machines

Tattoo machines are a popular product, often designed to attract attention with bright colors. This year, we began collaborating with a British tattoo machine company. Their products target the high-end tattoo market in Europe and North America, so they demanded high quality and appearance standards. They also requested us to assemble the tattoo machines while ensuring no scratches or stains appeared on the surface. They sent us some of their previous products to study and asked us to produce and assemble the new ones accordingly. We mainly produced foot pedal components, handles, power adjustment buttons, and other parts. Before assembly, we had a video conference with the customer to discuss the assembly and packaging process. After undergoing training for assembling tattoo machines, our employees quickly and efficiently assembled each unit. Once assembly was complete, our inspection team ensured that every machine was fully functional.

At MQJM, we not only provide high-quality custom CNC parts but also offer assembly and custom packaging services to meet the diverse needs of our clients. If you have a CNC project, feel free to contact us online and submit your drawings for a quote.