With the rapid development of science and technology, CNC (Computer Numerical Control) machining technology is more and more widely used in the field of bicycle parts manufacturing. CNC machining has revolutionised the bicycle industry with its high precision, high efficiency, flexibility and repeatability. Below, we will discuss the advantages of CNC bicycle parts from four subheadings.

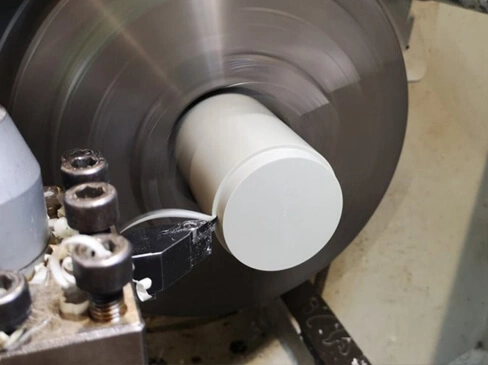

High-precision Machining to Enhance the Performance of Parts

CNC machining technology through the computer program control machine tool for automatic processing, can achieve very high processing accuracy. In bicycle parts manufacturing, high precision machining means more accurate dimensions, smoother surfaces and more reliable fit. This not only improves the performance of the part, but also ensures the stability and safety of the entire bike. Whether it's the frame, wheel hub or other key components, CNC machining technology ensures the quality of CNC bicycle parts for a smoother, safer ride.

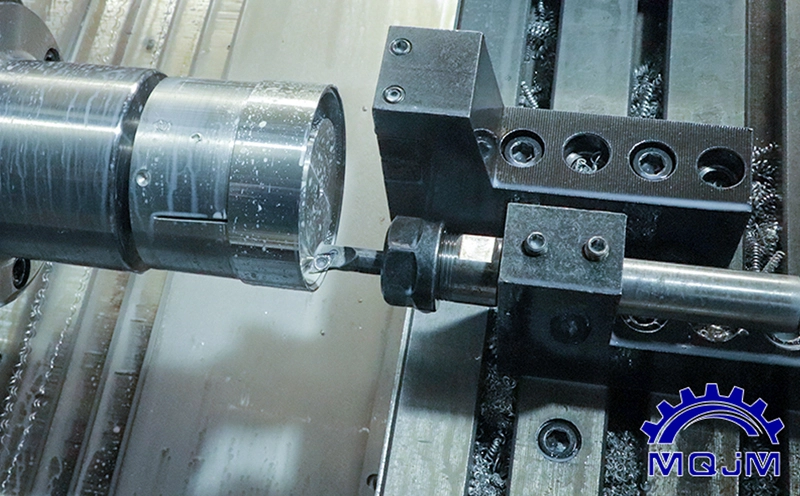

High Efficiency Production, Shorten the Delivery Cycle

Compared with the traditional manual processing or mechanical processing methods, CNC machining has a higher production efficiency. Through the pre-set machining procedures, CNC machine tools can process continuously and stably, which greatly improves the production efficiency. CNC machining is also highly automated, reducing manual intervention and error rates. These advantages make CNC machining can produce high-quality bicycle parts faster, so as to shorten the delivery cycle and meet market demand.

Strong Flexibility to Adapt to Individual Needs

CNC machining technology has a strong flexibility, can be adapted to different specifications, different shapes of parts processing needs. In the bicycle industry, with the increasing demand for personalised and customised products, the advantages of CNC machining technology are more and more prominent. By adjusting the machining program and parameters, CNC machine tools can easily achieve a variety of complex shapes, to meet the individual needs of customers. At the same time, CNC machining can also achieve small batch, multi-species production, reducing production costs and inventory risk.

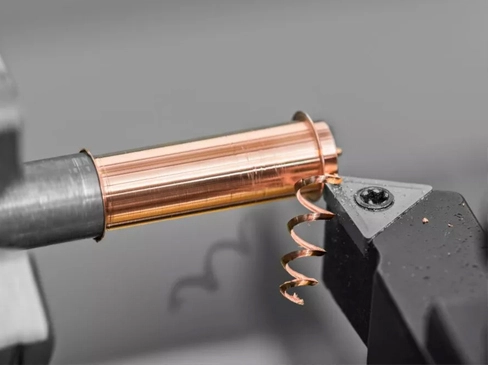

Good Repeatability, Ensure Product Quality

CNC machining technology is highly repeatable. Once set up the processing procedures and parameters, CNC machine tools can be processed in accordance with the preset trajectory to ensure that the results of each processing are consistent. This repeatability not only ensures consistent product quality, but also reduces the rate of defects and rework. In the bicycle industry, high-quality parts are the key guarantee for the performance of the entire bike. CNC bicycle parts produced through CNC machining technology have higher reliability and durability, which can provide consumers with a better riding experience.

In short, CNC machining technology has significant advantages in the field of bicycle parts manufacturing. Through the characteristics of high precision machining, high efficiency production, high flexibility and good repeatability, CNC machining has brought about a revolutionary change in CNC bicycle parts as well as the bicycle industry. With the continuous progress of technology and the expansion of the scope of application, we believe that CNC machining technology will continue to inject new vitality into the bicycle industry in the future.