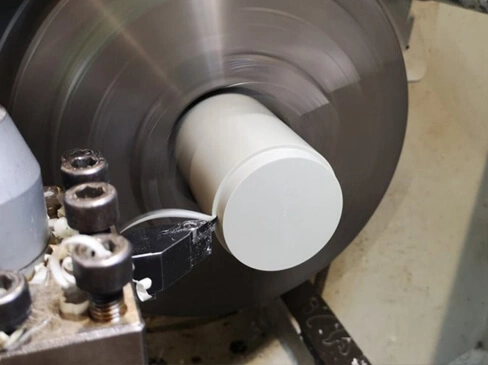

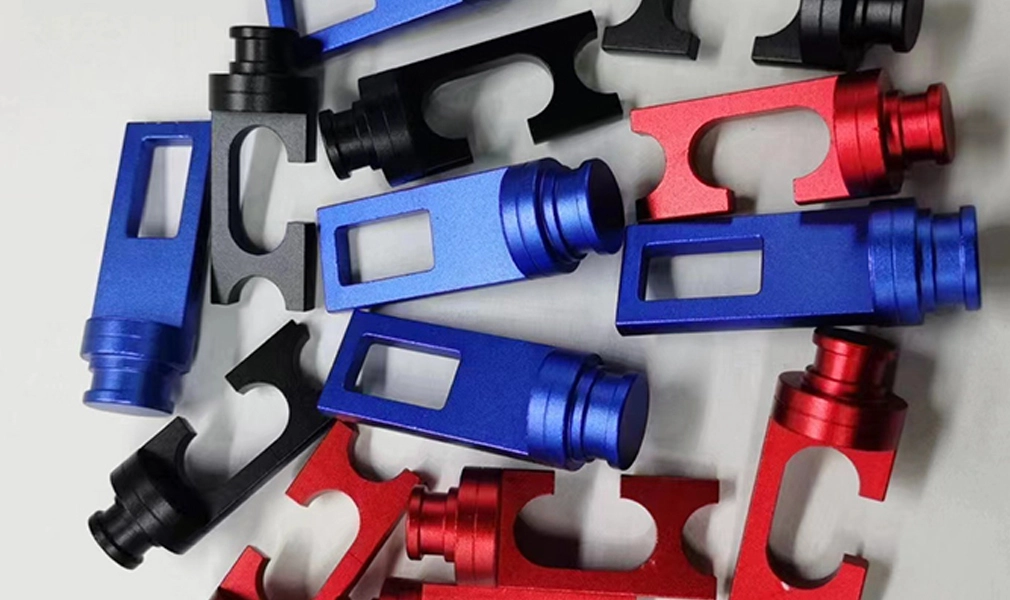

There are some significant differences between aluminum CNC machining and steel CNC machining, mainly due to the different material properties and processing characteristics of aluminum and steel. MQJM is a factory specialized in CNC machining, dedicated to providing high-quality machining services for customers. With rich experience and advanced equipment, they can handle various materials, including aluminum, stainless steel, brass, and more, to meet the needs of customers.

When it comes to machining, several differences need to be considered:

Material Hardness and Strength:

Aluminum is typically softer than steel, with lower hardness and strength. This means that the machining process for aluminum may be easier as it requires less cutting force.

Steel is generally harder and stronger than aluminum, thus requiring greater cutting force for machining.

Tool Selection:

Due to its softness, aluminum can often be machined using higher-speed cutting tools, such as high-speed steel or carbide tools.

Steel machining typically requires harder cutting tools, usually made of carbide or coated with special materials, to effectively cut the harder material.

Machining Parameters:

Aluminum usually requires higher cutting speeds and smaller feed rates to achieve good machining results while avoiding issues caused by excessive heat.

Steel typically needs lower cutting speeds and higher feed rates to prevent excessive tool wear or overheating while ensuring effective cutting of the material.

Cooling Requirements:

Since steel machining often generates more heat, more coolant is needed to lower the temperature and extend the tool life.

Aluminum machining requires less coolant as it generates less heat during the process.

Surface Treatment:

Steel often requires additional surface treatment steps, such as heat treatment or coating, to improve its corrosion resistance, hardness, or other properties.

Aluminum generally requires less additional surface treatment as it inherently possesses good corrosion resistance and lightweight properties.

As a professional CNC service factory, MQJM continuously strives to improve its technical capabilities and optimize its processes to ensure the provision of high-quality machined parts for customers and meet the needs of various industries.