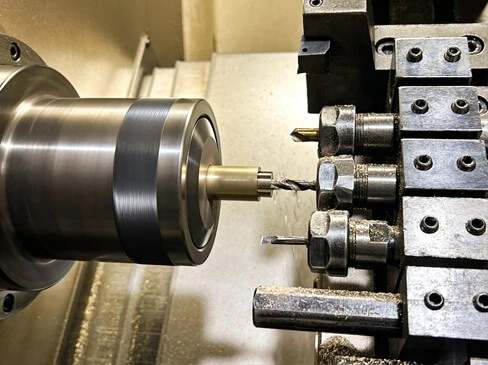

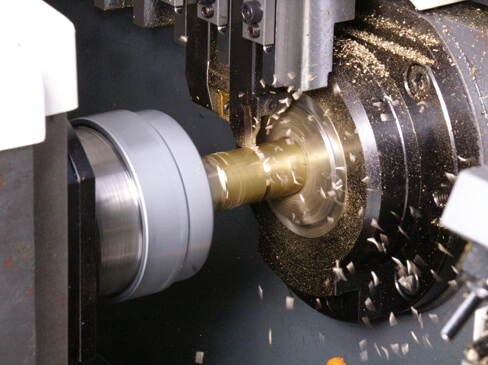

In CNC milling from MQJM, common surface finishing methods include the following:

1.Polishing:

- Mechanical Polishing: Uses abrasive tools (such as sandpaper, polishing cloth) to remove fine burrs and roughness from the workpiece surface, achieving a smooth finish.

- Electropolishing: Achieves a smooth surface through electrochemical reactions, commonly used for stainless steel, aluminum alloys, and other materials.

- Chemical Polishing: Uses chemical solutions to micro-etch the workpiece surface, achieving a bright finish.

2. Sandblasting:

- Uses high-pressure air to blast sand particles (such as quartz sand, corundum) onto the workpiece surface, removing oxidation, rust, and other contaminants, resulting in a uniformly rough surface. Suitable for cleaning, deburring, and surface texturing.

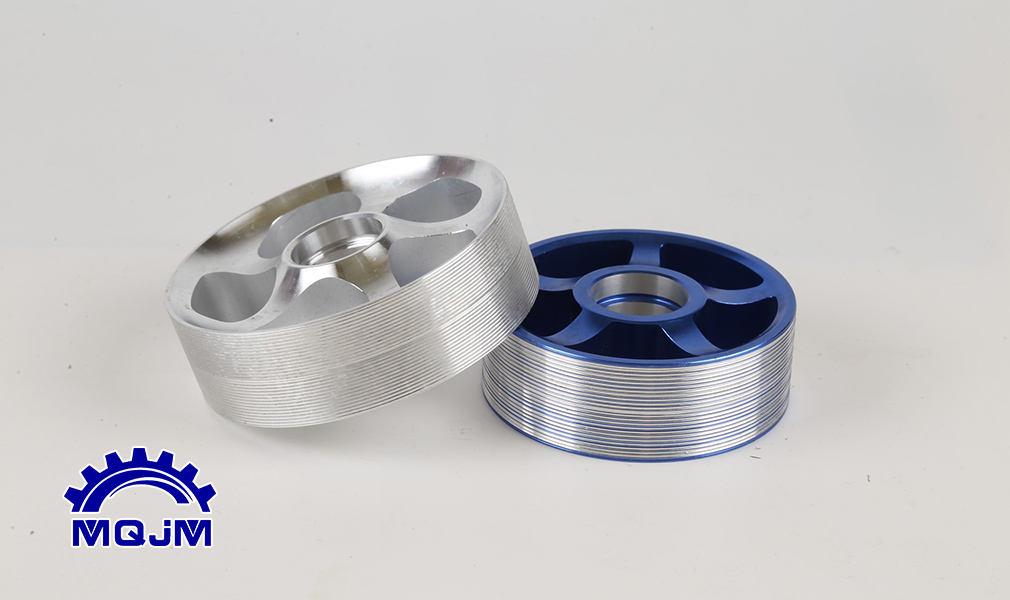

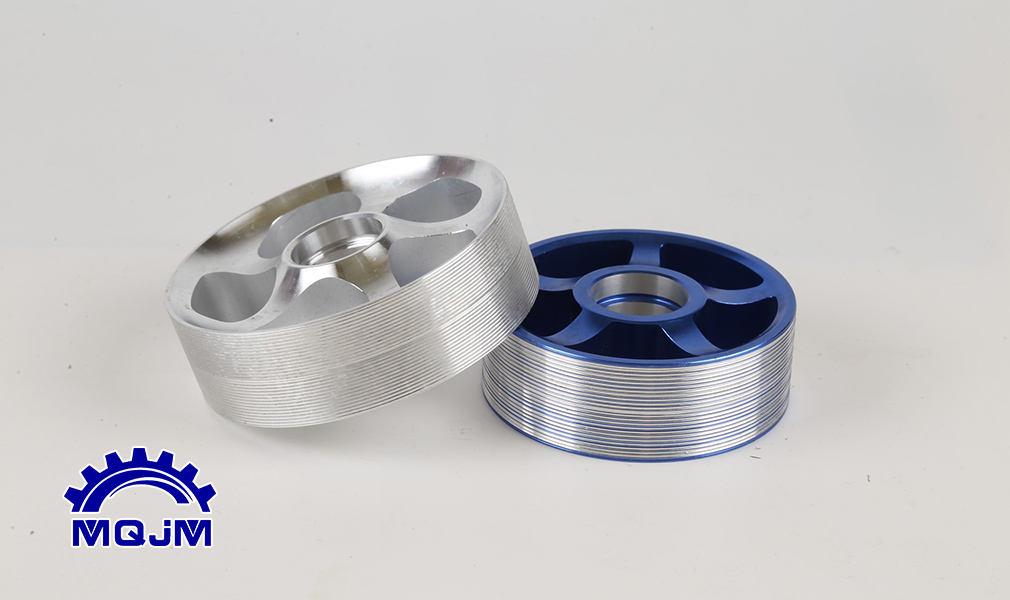

3. Anodizing:

- Electrochemical oxidation of aluminum and its alloys to form an oxide layer on the surface, enhancing corrosion resistance, hardness, and aesthetics. Anodized coatings can come in various colors, often used for decorative purposes.

4. Electroplating:

- Deposits a layer of metal (such as nickel, chrome, zinc) on the workpiece surface through electrolysis, improving corrosion resistance and decorative appearance.

5. Passivation:

- Mainly for stainless steel, chemically treats the surface to remove iron contaminants, forming a protective oxide layer that enhances corrosion resistance.

6. Black Oxide:

- Creates a black oxide layer on the workpiece surface through chemical reactions, enhancing corrosion resistance and improving surface appearance.

7. Powder Coating:

- Electrostatically applies powder coating to the workpiece surface, followed by high-temperature curing to form a hard protective film. It offers excellent corrosion and wear resistance, with various colors and textures available.

8. Laser Etching/Engraving:

- Uses a high-energy laser beam to etch the workpiece surface, creating permanent markings such as patterns or text. Suitable for identification, decoration, and functional surface treatment.

9. EDM Texturing:

- Forms fine textures on molds or workpiece surfaces through electrical discharge machining, enhancing the appearance and feel of the workpiece.

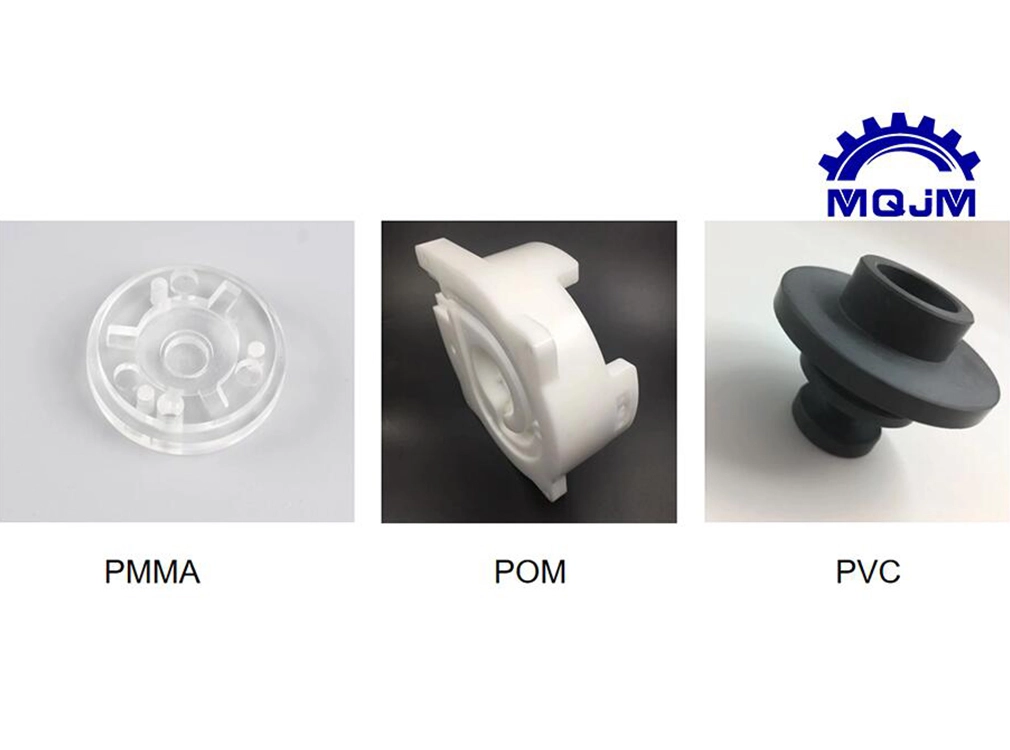

These surface treatment methods each have their characteristics and applicable ranges. Choosing the appropriate method according to specific machining requirements and workpiece materials can significantly improve the surface quality and performance of CNC milling parts.