Brakes and shifting are essential functions in all racing cars, and the shift knob is the key component for smooth shifting. During intense driving, the shift knob directly impacts the car's handling and performance. Therefore, a high-quality shift knob should not only be ergonomically designed but also made from suitable materials to provide the best feel and durability.

MQJM is a professional CNC precision machining manufacturer with over 14 years of experience in CNC turning and CNC milling. We have provided various car parts, including precisely designed and manufactured shift knobs, to numerous customers in the modified racing car and sports car industries. Our products cover a wide range of materials to meet the diverse needs and preferences of our clients.

Plastic Shift Knobs: Lightweight and Practical Choice

Plastic cnc shift knobs are widely used in many racing cars and sports cars. Common materials include ABS (Acrylonitrile Butadiene Styrene), POM (Polyoxymethylene), and Nylon. These materials are popular due to their light weight, excellent wear resistance, and low cost. ABS offers a comfortable grip and strong impact resistance, making it suitable for high-frequency, long-term use. POM, on the other hand, has superior self-lubricating properties, ensuring smoother shifting.

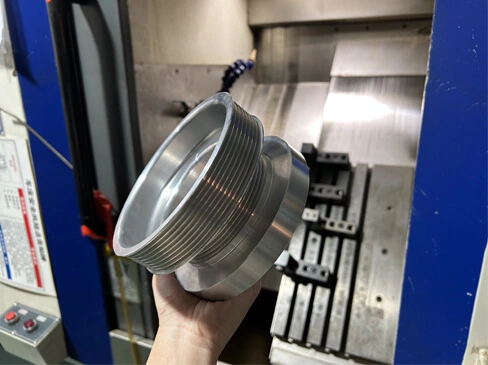

Aluminum Shift Knobs: The Perfect Balance of Weight and Strength

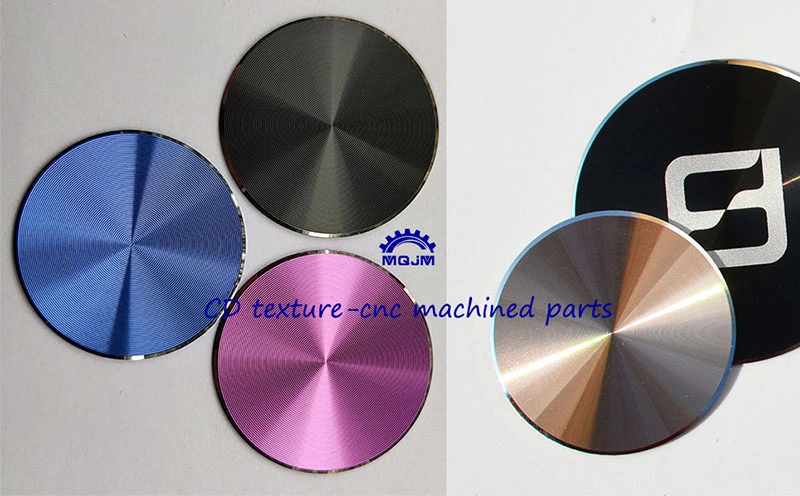

Custom Aluminum shift knobs are favored for their lightweight and high strength, making them ideal for drivers seeking performance and control. Common aluminum alloys include 6061 and 7075, which are not only light but also offer excellent corrosion resistance and high strength. In addition, there are various surface treatments available for aluminum knobs, such as anodizing, sandblasting, and polishing. These treatments not only enhance the aesthetic appeal but also improve durability, ensuring the shift knob retains its shine even after long-term use.

Stainless Steel Shift Knobs: Stability and Durability at Its Best

Stainless steel shift knobs are a premium choice among racing enthusiasts, primarily using 304 or 316 stainless steel. These knobs are heavier, providing a more solid and substantial feel, ideal for drivers who prioritize stability and durability. Compared to other materials, stainless steel shift knobs offer superior corrosion resistance, making them suitable for use in high humidity or extreme conditions. Additionally, stainless steel has exceptional wear resistance, allowing it to withstand frequent shifts and maintain consistent performance over time.

MQJM: Experts in Custom Racing Parts

As a professional CNC precision machining manufacturer specializing in high-quality custom racing parts, MQJM is committed to delivering unparalleled products and services to our customers. All of our products undergo strict quality control before shipment, ensuring a scratch-free surface, with meticulous surface treatments that guarantee a flawless and durable finish. Our CNC customer services are not only flexible and diverse but also reasonably priced, ensuring that every customer receives an exceptional value for their investment.