With the continuous development of technology, the manufacturing industry is also constantly innovating. Among them, CNC multi-axis machining technology, with its efficient and precise characteristics, is gradually changing the traditional manufacturing production mode and becoming the new engine of future manufacturing.

I. Concept and Characteristics of CNC Multi-Axis Machining

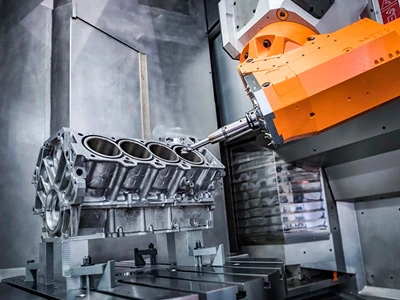

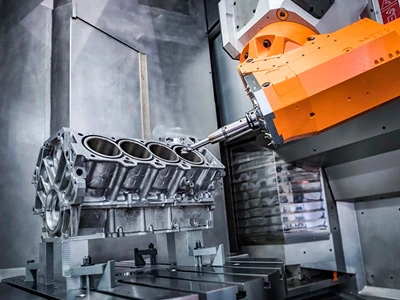

CNC multi-axis machining refers to the control of multiple axes through the numerical control system on the CNC machine tool to achieve the processing of complex parts. This processing method has high precision, high efficiency, and high degree of automation, which can meet the modern manufacturing industry's processing needs for high-precision, complex-shaped parts.

The emergence of CNC multi-axis machining technology has realized rapid CNC machining and greatly improved the production efficiency of the manufacturing industry. It can not only achieve one-time forming of complex parts, reducing the time for multiple clamping and adjustments but also optimize the tool path to reduce processing time and improve production efficiency.

II. Application of CNC Multi-Axis Machining in Manufacturing

CNC multi-axis machining technology has been widely used in the aviation, automotive, mold, electronics, and other industries. In the aviation industry, complex surface parts, high-precision parts, and large-scale parts production all rely on CNC multi-axis machining technology. In the automotive industry, CNC multi-axis machining technology can achieve efficient and high-precision processing of automotive parts, improving the performance and quality of cars.

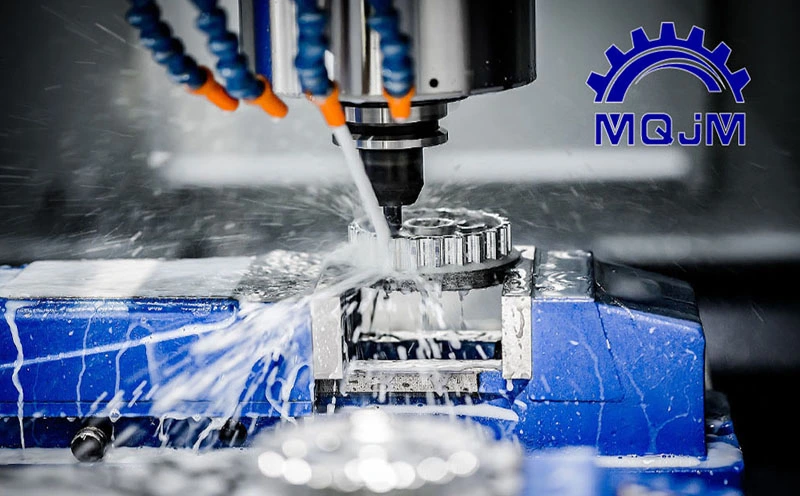

In addition, CNC multi-axis machining technology also plays an important role in mold manufacturing and electronic product manufacturing. It can achieve rapid and precise manufacturing of molds, improving the quality and service life of the molds. In electronic product manufacturing, CNC multi-axis machining technology can achieve precise processing of tiny parts, improving the performance and reliability of electronic products.

III. Future Development Trend of CNC Multi-Axis Machining

With the continuous development of technology, CNC multi-axis machining technology will also continue to progress. In the future, CNC multi-axis machining technology will be more intelligent and automated, capable of achieving more complex and precise parts processing.

Firstly, CNC multi-axis machining technology will be more intelligent. By introducing artificial intelligence, big data, and other technologies, intelligent optimization of the processing process can be achieved, improving processing efficiency and precision. Secondly, CNC multi-axis machining technology will be more automated. By introducing robots and other automated equipment, unmanned production can be achieved, reducing production costs and improving production efficiency.

In summary, CNC multi-axis machining technology, with its efficient and precise characteristics, is gradually changing the traditional manufacturing production mode and becoming the new engine of future manufacturing. With the continuous development of technology, the application of CNC multi-axis machining technology will be more widespread, and its development prospects are very broad.