Recently, Ming received an inquiry from a client in Poland, an experienced engineer working in the tattoo machine industry. The engineer was looking for a CNC machining company capable of providing high-quality CNC machining parts service and housing for their tattoo machines. Not only did he require comprehensive CNC services, but he also wanted a factory with experience in producing tattoo machine components, to ensure precision and superior quality in every part.

Ming confidently introduced the capabilities of MQJM to the client. Over the years, MQJM has provided CNC machining parts service for tattoo machine housings and parts to clients worldwide. We meet rigorous quality and surface treatment standards, with deep expertise in both aluminum and stainless steel tattoo machine parts. Here are some examples of our successful projects, showcasing our experience and expertise in CNC machining tattoo machine parts.

MQJM CNC Machining Parts Service Tattoo Machine Cases

1. Four Colors of Anodized Aluminum Tattoo Machine Housing

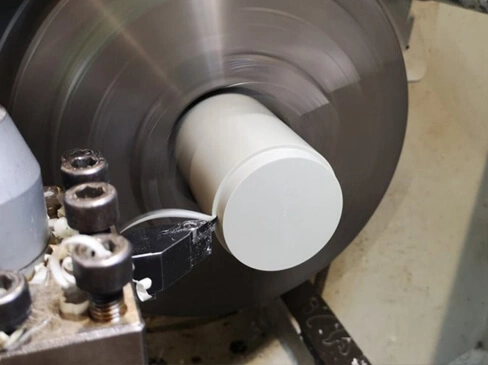

In 2020, a tattoo machine company from Italy, primarily targeting the European market, placed an order for anodized aluminum tattoo machine housings with us. After providing a simple housing design, the client sought our recommendations for surface treatments. MQJM suggested sandblasting and anodizing after CNC turning to enhance the aesthetic appeal and durability of the housing. We offered four anodized colors, giving the tattoo machine housing both reliability and visual appeal.

This order included 2,000 tattoo machine housings, and MQJM completed the production, quality inspection, assembly, and packaging within just 20 days. The client was delighted with the flawless surface finish of each housing, which helped them gain positive attention in the market.

2. High-Strength Stainless Steel 316 Tattoo Machine Parts

At the end of 2022, a long-time client placed an order with us for 500 stainless steel 316 tattoo machine parts. This order required an exceptionally smooth surface finish and precision within a tolerance of ±0.03. Despite the hardness and machining difficulty of stainless steel 316, MQJM leveraged its expertise in stainless steel CNC processing and advanced equipment to deliver high-quality components. The smooth surface and precise tolerances impressed the client, strengthening our long-term partnership.

3. Custom Black Anodized Tattoo Machine

Mr. Jenny, a friend of one of our long-term clients, approached Ming with plans to create a new tattoo machine brand. Mr. Ming and the engineering team worked closely with Mr. Jenny to refine his design drawings and offered constructive suggestions to optimize the functionality of the final product. Within just two weeks, MQJM completed the prototype of a black anodized tattoo machine, which impressed Mr. Jenny with its sleek finish and flawless assembly. Soon after, he placed a bulk order.

Thanks to the high quality of our CNC machining parts service, Mr. Jenny's tattoo machines quickly gained a loyal customer base in the U.S.

4. Complex Tattoo Machine Design with 5-Axis CNC Machining Parts Service

In 2024, we manufactured a complex, non-standard tattoo machine for a client, Thomas. This unique design featured intricate curved surfaces, requiring at least 5-axis CNC machining parts service to achieve the desired result. Initially, Thomas wanted to use steel for the housing. After a detailed evaluation, we recommended using aluminum 6061 or 7075 instead, as these materials would better meet the precision and tolerance requirements while also reducing production time and cost.

Thomas trusted our professional advice, and we delivered an anodized aluminum tattoo machine housing that met all specifications. Upon receiving the product, the client was thrilled, and his customers loved the tattoo machine's design and quality.

These examples showcase MQJM's professional CNC machining parts service capabilities and commitment to providing end-to-end custom tattoo machine part solutions. Whether it’s an anodized aluminum tattoo machine housing or precision stainless steel tattoo machine components, we are equipped to meet high standards for accuracy and quality. MQJM’s extensive experience, fast turnaround times, and attentive customer service make us a trusted CNC machining parts service partner for tattoo machine brands worldwide.

By choosing MQJM’s precision CNC services, you gain access to durable, precision-engineered tattoo machine CNC parts and customized solutions to give your products a competitive edge.