.jpg)

MQJM's Strengths and Features

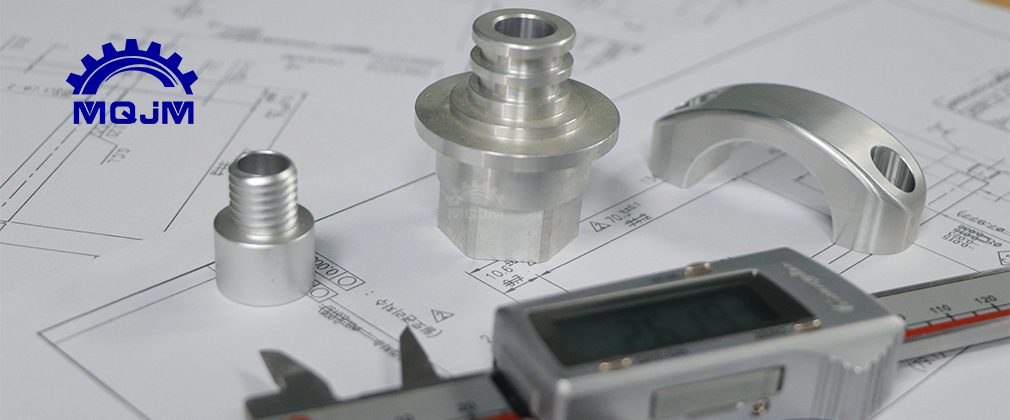

MQJM is a Shenzhen-based factory specializing in processing and manufacturing CNC milled aluminum parts and products. Since its establishment in 2010, we have successfully produced over 2,000 types of aluminum milled parts. We are proud to provide customized aluminum CNC milling services to numerous companies worldwide, fostering long-term and fruitful partnerships. So, how does MQJM ensure the quality of CNC milled aluminum products?

1. Strict Control Over Material Quality

Material quality is the foundation of high-precision aluminum CNC milled parts. To guarantee this, we have a dedicated incoming material inspection department that tests each batch of materials and requires suppliers to provide detailed inspection reports. Only aluminum materials with high purity and performance that meet customer requirements proceed to production.

We offer CNC milling services for various premium aluminum alloys, including 6061 aluminum, 6063 aluminum, 6082 aluminum, and 7075 aluminum, ensuring flexibility in meeting diverse customer needs for 6061 aluminum CNC milling and 7075 aluminum milled parts. We also recommend the most suitable materials based on the specific application, ensuring optimal performance.

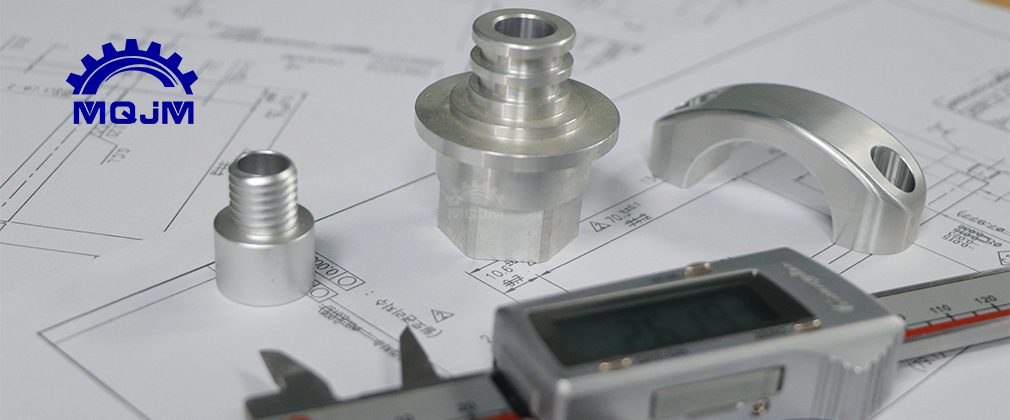

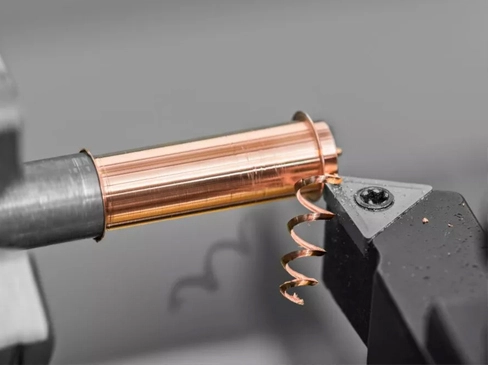

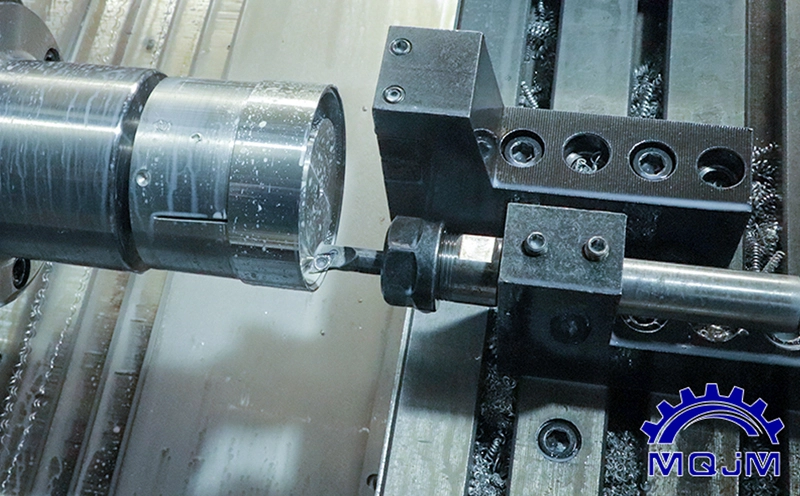

2. Precision in the Milling Process

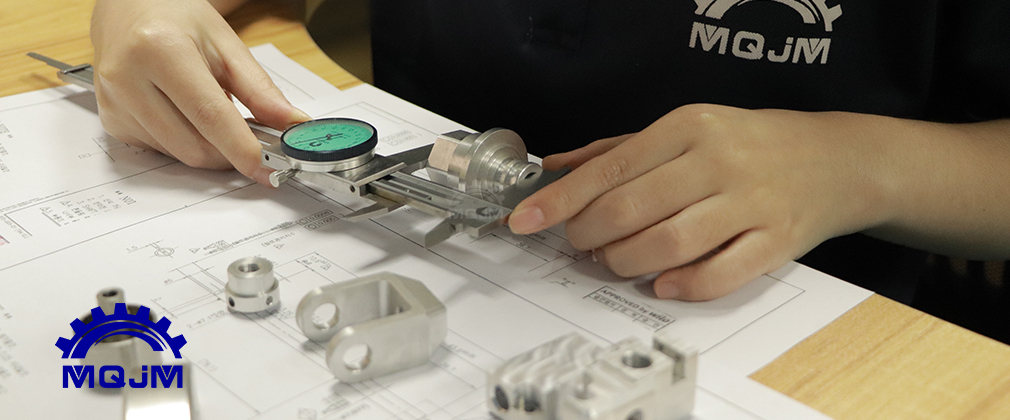

The machining process is one of the most critical steps in ensuring product quality. MQJM's production team comprises experienced professionals who are dedicated to producing high-quality aluminum CNC milled products.

Accurate Programming and Fixture Design: Our programmers design fixtures to secure parts firmly while avoiding damage, scratches, or dents during machining.

Rigorous In-Process Inspection: During production, operators conduct regular inspections of surface finishes, hole locations, and threading to promptly address any issues.

Attention to Detail: We meticulously control tolerances, ensuring that each aluminum alloy CNC milled part meets the exact specifications provided by the client.

3. High-Standard Surface Treatments

Surface treatment is essential for CNC milled aluminum products. It enhances not only the appearance but also the durability and performance. At MQJM, we follow strict standards to ensure surface treatments meet customer requirements:

Anodizing: Provides corrosion resistance and high-strength surface protection while offering aesthetic color options.

Sandblasting: Creates a uniform finish, enhancing the tactile feel and visual quality of the product.

Other Custom Finishes: Services such as polishing and plating are available to ensure aluminum CNC milled parts meet your exact specifications before delivery.

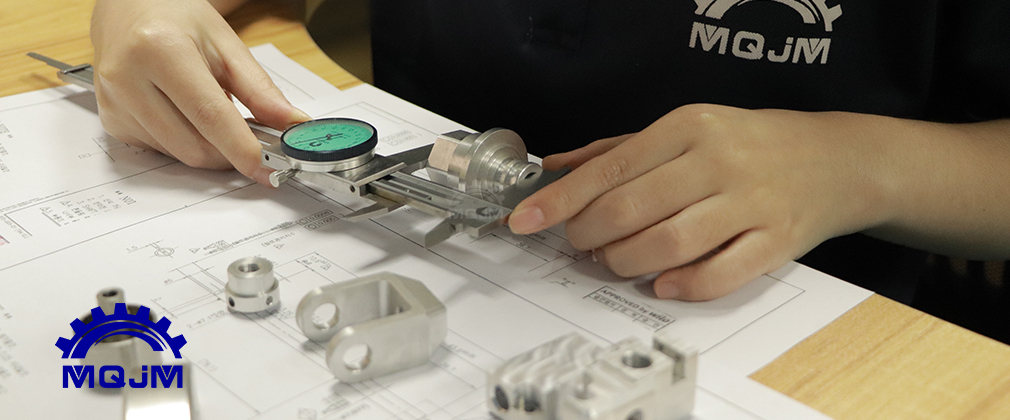

4. Comprehensive Quality Inspections

Inspection is an integral part of our aluminum CNC milling process.

Marking Critical Areas: Before production, we mark key areas on the blueprint for focused quality checks.

Regular In-Process Inspections: During production, we perform inspections every 30 minutes to 1 hour, checking dimensions and surface quality to maintain consistency.

Post-Processing Inspections: For unfinished parts, we conduct random checks with a sampling rate of 5%-10% to ensure accuracy.

Final Full Inspection: Before shipment, every part undergoes a 100% full inspection, ensuring that aluminum CNC milled products meet the highest quality standards.

From material selection to machining, surface treatment, and final inspection, MQJM upholds strict quality control standards to deliver exceptional aluminum CNC milled parts. Whether you need 6061 aluminum milling or 7075 aluminum milled parts, our commitment to quality and professional service ensures customer satisfaction. If you're seeking a reliable partner for China cnc milling service, MQJM is the right choice for you!

.jpg)