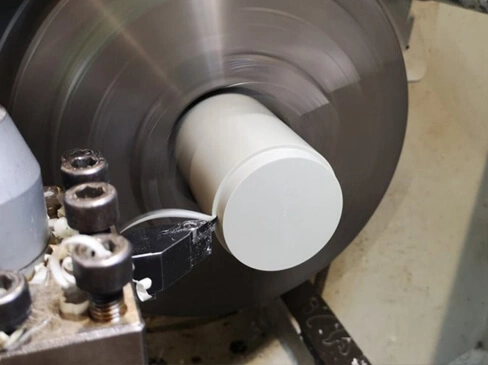

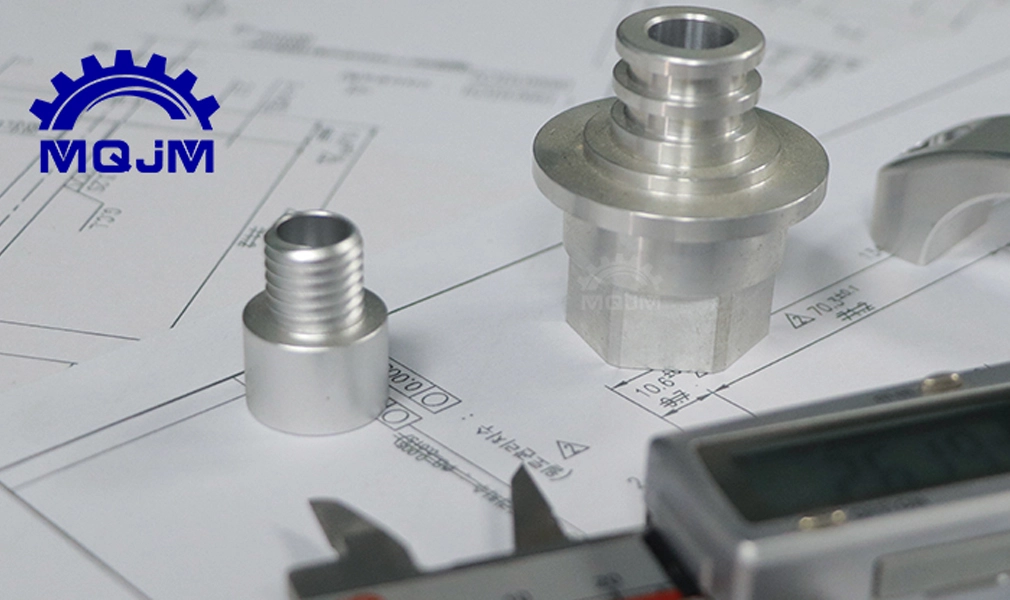

MQJM recently received a CNC online inquiry from a customer, who mentioned that the aluminum 7075 parts purchased from other suppliers had surface corrosion problems and had not been effectively resolved. After discussing with the engineer, we analyzed the causes of corrosion and proposed corresponding protective measures.

1. Causes of corrosion of aluminum 7075

①Oxidation corrosion: Aluminum 7075 is a high-strength aluminum alloy, but it is also more susceptible to oxidation corrosion, especially in humid environments.

②Electrochemical corrosion: When aluminum 7075 comes into contact with other metals, it is prone to electrochemical corrosion due to potential difference.

③Processing or cleaning residues: If acidic or alkaline substances remain on the surface after processing or cleaning, corrosion may also be aggravated.

④Lack of effective surface treatment: Surface protection (such as anodizing or anti-corrosion coating) that is not performed or improperly treated will accelerate corrosion.

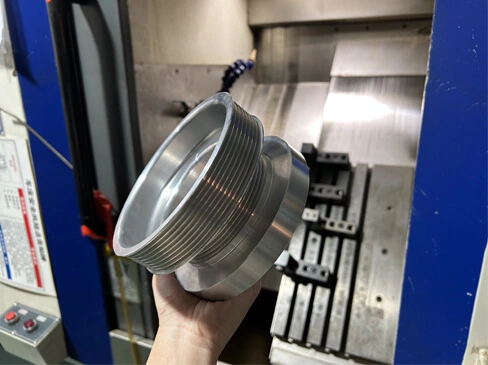

2. Measures to prevent corrosion of aluminum 7075

①Surface anodizing: Anodizing can form a protective film on the surface of aluminum alloy to enhance its corrosion resistance.

②Coating protection: Polymer coatings or other anti-corrosion materials can be used after anodizing to further protect the surface.

③Avoid contact between dissimilar metals: Each MQJM machine is dedicated to machining only one material, avoiding direct contact between aluminum 7075 and metals such as copper and steel to reduce the risk of electrochemical corrosion.

④Cleaning and drying: The surface of the processed aluminum parts should be kept clean and avoid humid environments.

⑤Control the environment: During the use or storage of parts, try to avoid long-term exposure to high humidity or marine environments.

These measures effectively prevented corrosion of the 7075 aluminum parts during CNC machining for this customer. We assure our customers that in future production, MQJM will strictly control the machining and surface treatment processes to ensure that the parts provided can maintain a good surface even when they are extremely susceptible to corrosion.