There are many materials suitable for CNC turning, and finding the right material for a product is governed by many factors. When choosing CNC turning material, you can consider the following 5 aspects.

Rigidity of CNC Turning Material

Rigidity is the first factor to consider when choosing the material since the product needs a certain stability and wear resistance in the actual work. The rigidity of the material determines the feasibility of the product design. Non-standard tooling design usually choose 45 steel and aluminum alloy. For machining tooling design, 45 steel and alloy steel are used more; for automation industry tooling design, aluminum alloy is mostly chosen.

CNC Turning Material Stability

For a high-precision requirements of the product, if it is not stable enough, after assembly will occur a variety of deformation, or the use of the process of deformation again. In short, products will continue to deform in response to environmental changes such as temperature, humidity and vibration.

CNC Turning Material Processing Performance

The machinability of CNC turning material means whether the part is good to machine or not. Although stainless steel is rust-proof, stainless steel is not good for machining, its hardness is high, and it is easy to wear the tool during machining. Machining small holes in stainless steel, especially threaded holes, is easy to break the drill bit, but also easy to break the tap, which will lead to very high processing costs.

CNC Turning Material Cost

Cost is an important consideration in choosing a material. For example, titanium alloy is light in mass, high in specific strength and good in corrosion resistance, and is widely used in automobile engine systems, playing an immeasurable role in energy saving and consumption reduction.

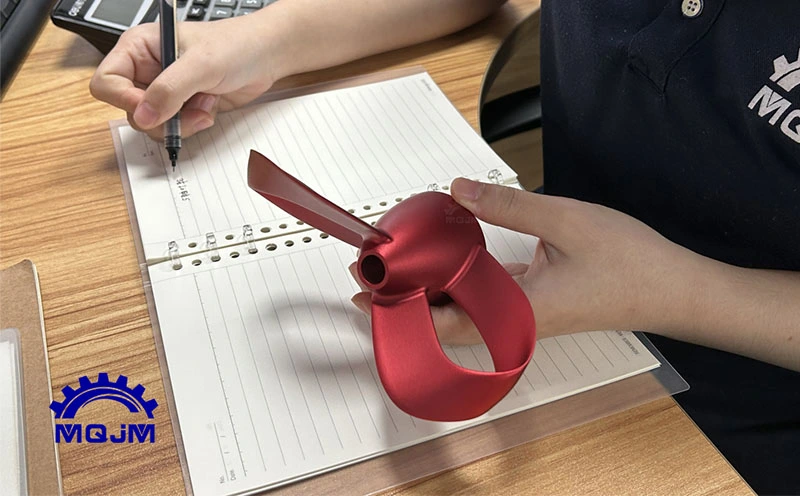

Shenzhen Mingqiang Precision Hardware Products Co., LTD., is a professional CNC machining manufacturer. MQJM specialises in CNC turning and milling and has more than 13 years of manufacturing experience. We keep adopting advanced production facilities to improve efficiency and ensure high and stable quality, and further reduce the production cost. The objective is to create reliable, viable and affordable product, CNC machining parts and fast sample service for every industry. If you are looking for CNC turning service, we will be your trustworthy choice.