Custom CNC aluminum refers to the manufacturing of aluminum parts or components according to specific designs and requirements using Computer Numerical Control (CNC) machining technology. CNC aluminum processing is widely used in various industries such as automotive, aerospace, electronic devices, medical instruments, etc. Its main advantages lie in high precision, strong repeatability, and the ability to produce parts with complex shapes.

Common Processes of Custom CNC Machined Aluminum

Design and Drawing

According to customer needs, a 3D model or drawing is first created, usually using CAD software to design the parts.

Programming

Once the design drawing is completed, a programming engineer converts it into G-codes that a CNC machine can recognize. This process uses CAM software for planning tool paths and cutting parameters.

Material Selection

Common types of aluminum include 6061, 7075, and 5052. Different aluminum alloys have different mechanical properties suitable for various applications.

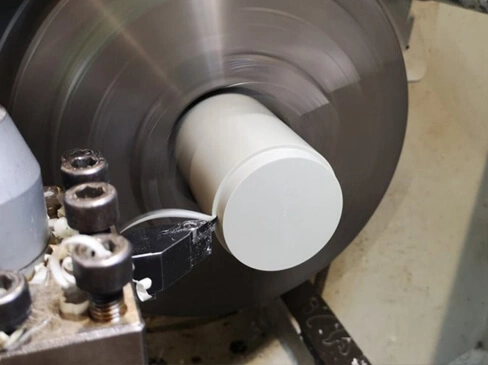

CNC Machining

Place the aluminum alloy into the CNC machine, which performs cutting, milling, drilling, and other machining steps according to the pre-programmed path. Common CNC machining methods include:

CNC Milling: Uses a rotating tool for cutting, primarily for plane and shape machining.

CNC Turning: Suitable for machining symmetrical parts, with the tool rotating relative to the workpiece.

CNC Drilling: Performs precise drilling operations.

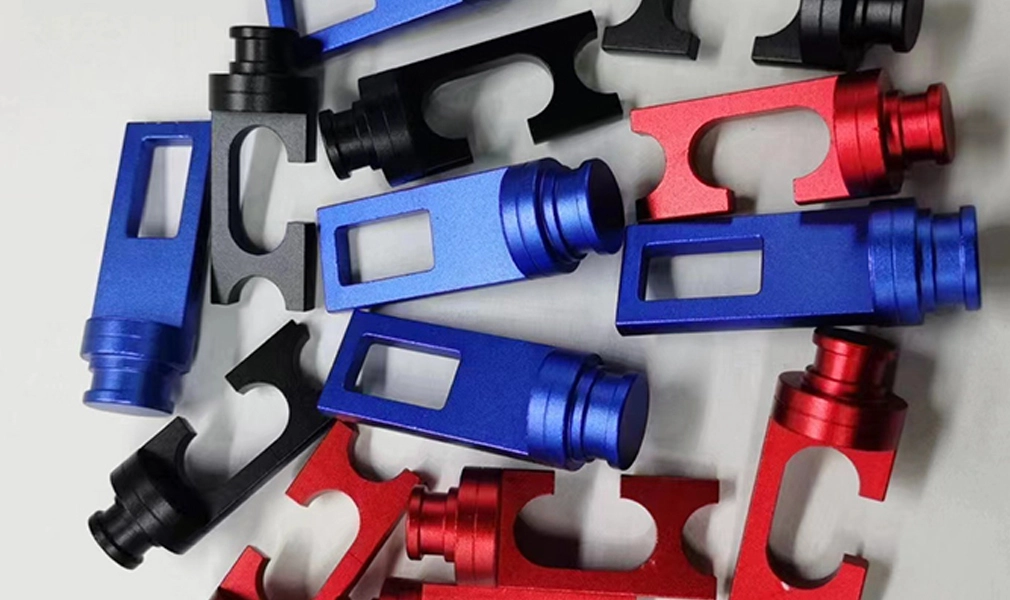

Surface Treatment

Depending on the requirements, the finished product undergoes surface treatments such as polishing, anodizing, plating, etc., to enhance aesthetics and corrosion resistance.

Quality Inspection

Utilize precision instruments to measure the dimensions of the machined parts to ensure they meet design specifications.

Advantages of Custom CNC Aluminum

High Precision: CNC machining can achieve micron-level precision, making it particularly suitable for complex and high-demand parts.

Flexibility: Designs and production can be flexibly adjusted according to customer requirements without the need for substantial mold investments.

Fast Speed: Compared to traditional manual or mold production methods, CNC machining is fast, suitable for small batch or custom production.

Excellent Performance of Aluminum: Aluminum is light, highly corrosion-resistant, and has good electrical and thermal conductivity, making it very suitable for various industrial applications.

If you need custom CNC aluminum parts services, you can provide the drawings and requirements. MQJM, a professional CNC machined aluminum parts manufacturer, can produce according to your needs.