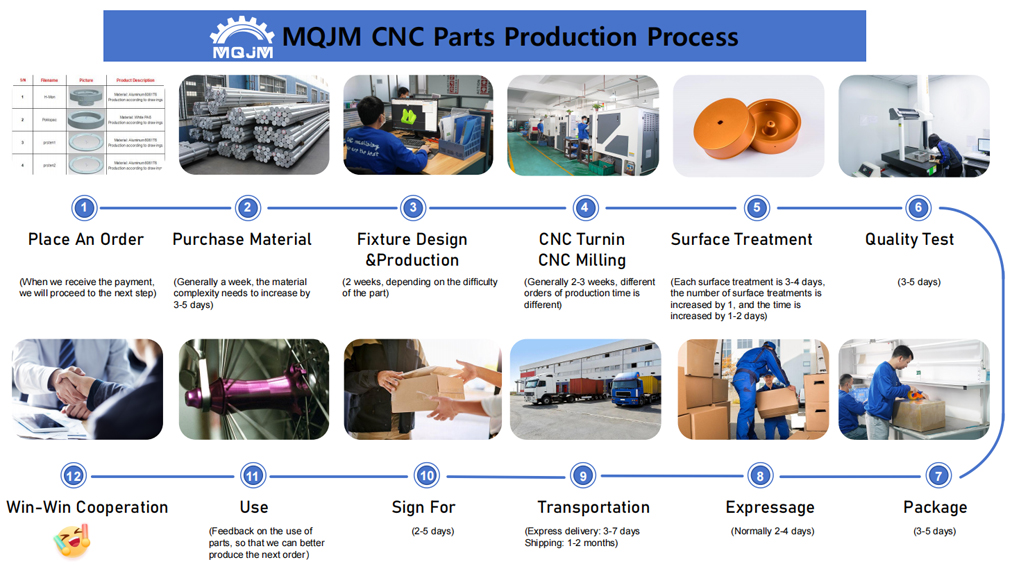

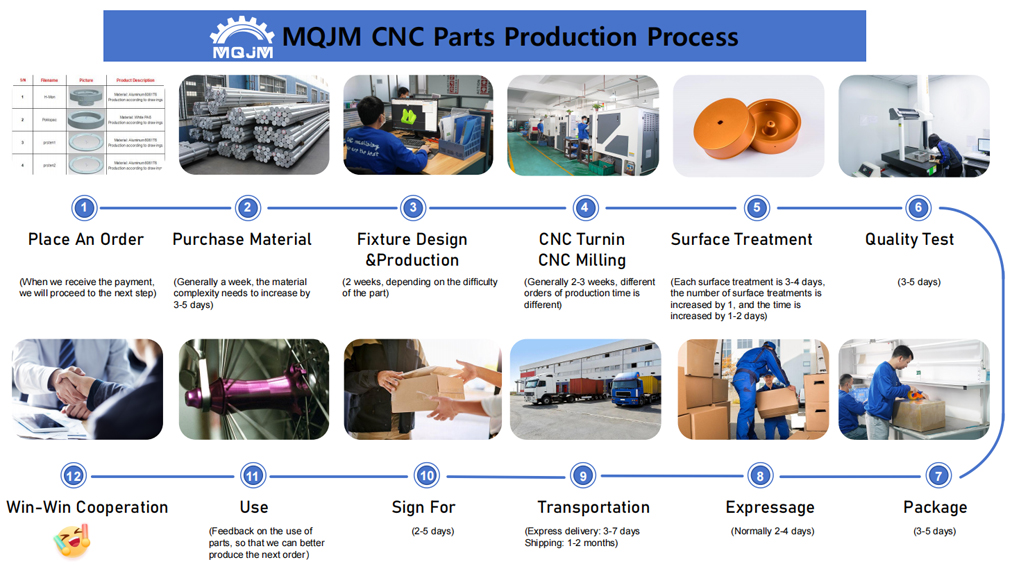

When you place an order with MQJM, how do we organize the production? How long will you receive your customized CNC machined parts? Since its establishment in 2010, MQJM has gradually built up a set of perfect production process and system, covering multiple specialized departments. Each department cooperates with each other to ensure quality CNC machining service for each customer. Below is the detailed process of MQJM from order confirmation to final delivery.

1. Arrange production after order confirmation

When a customer places an order, our finance department will be the first to check the amount and details of the order. After confirming the receipt of the payment and checking that it is correct, the finance department will issue a production order and allocate the funds to the purchasing department. At this point, the order formally enters the production process.

2. Material Purchasing

The purchasing department is responsible for purchasing materials with the appropriate specifications from suppliers according to the requirements of the order. For example, if your custom aluminum part size is 43*82*275mm, we usually purchase material with a size of 45*85*280mm. This allows for sufficient machining allowance, which ensures flexibility in machining and improves the yield of the finished product. Common materials include aluminum 6061-T6, 7075-T6, C110 copper, 304 stainless steel, free cutting steel and so on. If we encounter special materials such as 316S stainless steel, which are more difficult to procure, the procurement time may be extended by 3 days. Normally, the procurement cycle for regular materials is 3-5 working days, which also includes the transportation time.

For regular orders, we usually purchase 1-3 extra units of material at the time of purchasing to cope with any special circumstances that may arise during production; for new orders, we will prepare 5 extra units of material, not only to keep samples for possible future repetitions, but also to avoid mistakes during the first production. For regular customers, we will reserve the right amount of material in stock in order to start the production quickly and shorten the delivery time.

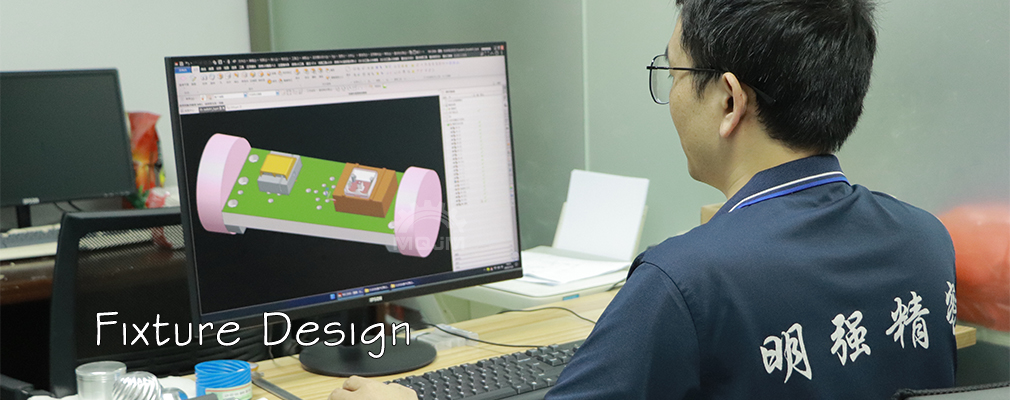

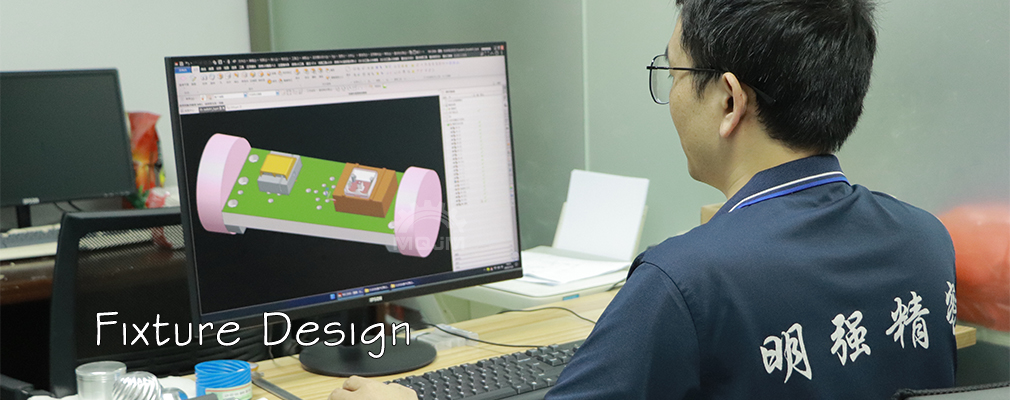

3. Fixture design and production

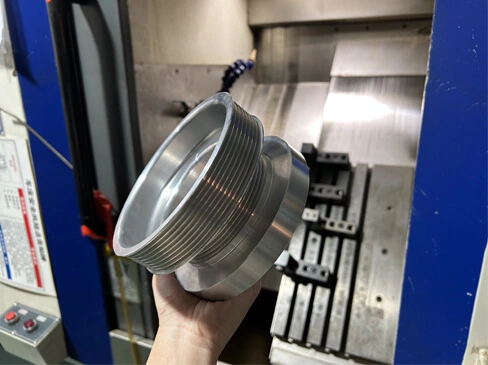

After the material arrives, the production department will arrange programming, jig production, CNC machining and surface treatment according to the order scheduling.MQJM's production department is divided into CNC turning, CNC milling, 5 Axis CNC machining. Each department has corresponding programming masters, machine tuning technicians and operators to ensure that the parts of each order can be processed in the right department.

Taking a part that requires turning and milling as an example, Ming, the production supervisor, would first evaluate the order in which the part is to be processed, whether it is to be CNC turned first or whether the surface texture and structure is to be dealt with through the CNC milling service first. In this example, we would use CNC turning to complete the basic shape and threads before handing over to the 3/4-axis milling department for surface preparation.

The accuracy of the programming is directly related to whether the finished product meets the customer's requirements.MQJM has a number of experienced programmers, three of whom have over 20 years of CNC programming experience. They design the fixtures, program the parts and simulate production for each product. A moderately difficult CNC part usually takes 2-4 working days to program. If the part is more complex or has tight tolerances, the programming time may increase by 3-4 days.

Once the fixture design is complete, we will begin production of the fixture. To ensure the quality of the fixture, MQJM's technical staff will fine-tune the machine to ensure that every step is accurate. Unlike other CNC factories, we don't go straight into mass production, but rather do a trial run of 1-2 parts to check for problems with the fixtures and programming. This method can greatly improve the yield rate and avoid batch errors.

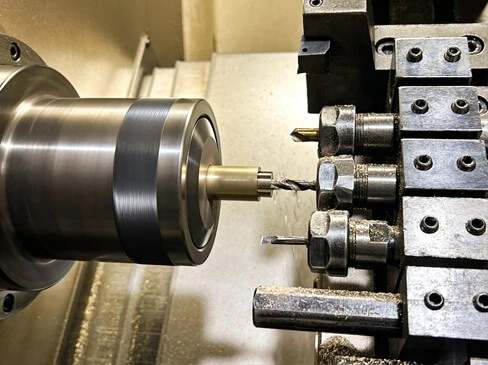

4. CNC parts machining

Formal part production will begin when the fixture trial production has been verified. Our operators will follow the following steps to execute the production:

1. Pick up the appropriate material from the warehouse and transport it to the designated machine tool.

2. Attach drawings, production notes and quantity requirements to each machine.

3. prepare suitable plastic frames and protective mats for each part to avoid damage to the parts during handling and machining.

During the production process, our quality inspectors conduct spot checks every 20-30 minutes, randomly selecting 2-5 parts at a time. In addition to this, every 2 hours we use specialized testing equipment to fully measure the size and quality of the parts. The production lead time is usually 1 week for small orders and 2-3 weeks for large orders. It is worth noting that aluminum parts are usually processed 2-3 days faster than other materials because it is softer and easier to work with.

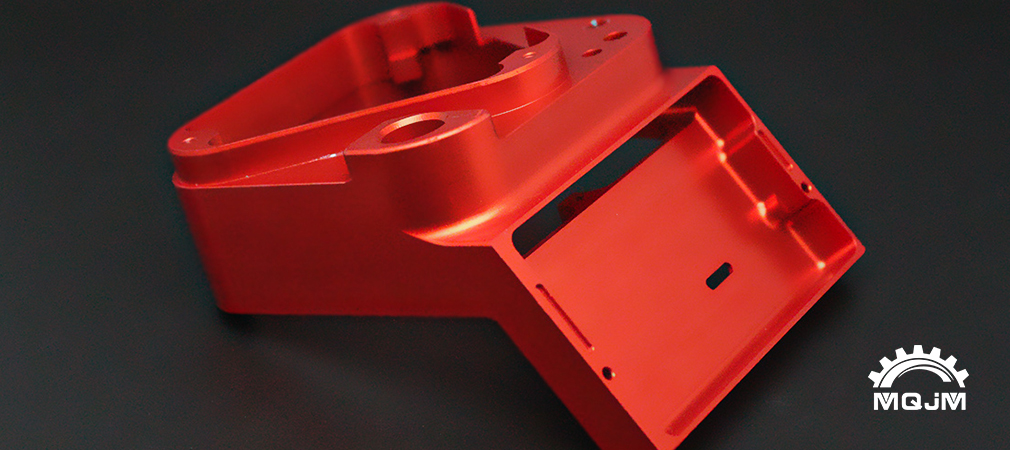

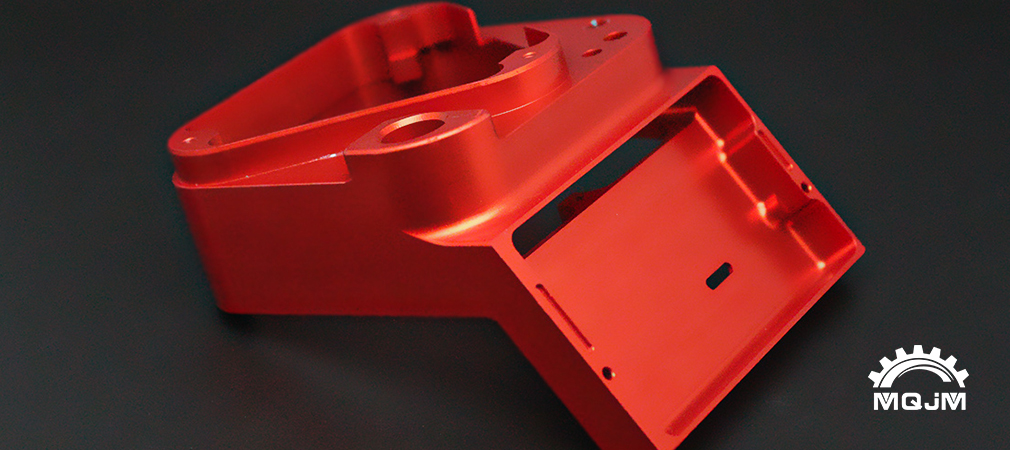

5. Surface Finishing

After CNC machining, the part enters the surface treatment stage. Common surface treatment methods include sandblasting, anodizing, polishing, plating, blackening, QPQ, etc. The time for common surface treatment is usually 2 days. The time for common surface treatment is usually 2-3 days, depending on the number of orders and the complexity of the parts.

For example, the aluminum CNC parts that needs to be anodized and overlaid with a brushed effect, the surface treatment time may extend to about a week. Anodizing takes 3 days and brushing takes 2 days. In addition, if the customer requires marking on the part, an additional 1-2 days are required to confirm the font and marking process.

6. Quality Control (QC)

High quality CNC parts are the key to MQJM's long-term cooperation with global customers. We have a professional QC team equipped with advanced testing equipment. Before each batch of parts is shipped, we conduct 100% quality inspection, including dimensions, threads and surface finish. Usually, the QC team can finish the quality inspection within 1-3 days. If the customer needs a detailed inspection report, the report production will take an additional 1-2 days.

7. Packing

After all the parts pass the quality inspection, they will enter the packing process. Generally speaking, it takes about 3 days for packing. For small orders of 10-50 pieces, packing can usually be done on the same day of QC and shipped on the same day. We also offer customized packaging and parts assembly services, which may add 2-5 days to the packing time.

8. Shipping

The choice of shipping method directly affects the final delivery time. If you choose express shipping (air freight), the parts will usually arrive within 2-7 days; while if you choose ocean freight, it may take 1-2 months.

9. Delivery time

For urgent orders, we will speed up the process by 2-3 days at each stage, and the fastest delivery can be within 20 working days. Under normal circumstances, the delivery time is 30-35 working days.

MQJM is committed to providing customers with high quality CNC machining services. From order confirmation, material procurement to part production, surface treatment, to final quality inspection and packing for shipment, we strive for excellence in every step of the process to ensure that each customer's order is delivered on time and to the customer's satisfaction. Through our perfect machining service system and experienced team, customers can rest assured that they can choose MQJM to enjoy efficient and reliable customized CNC parts machining services.