For parts that require precision at their core, controlling dimensional stability has always been a point of interest for metal manufacturers. Compared to other commonly used metals, the thermal expansion coefficient of aluminum alloys is much higher. Therefore, major deformation issues arise in various machining operations, such as thin-walled machining and forging. Apart from the internal stress and cutting forces in the material blank causing deformation, heat dissipation issues in the cutting operation and the clamping force during the machining process can also result in deformation. Therefore, controlling these deformations and optimizing the dimensional stability of aluminum CNC machining is crucial.

Aluminum CNC Machining: Eliminate Internal Stress in Materials

Common methods for eliminating internal stress in aluminum parts include natural or artificial aging and vibration treatment. Natural aging involves placing the workpiece under natural conditions such as outdoors, allowing the internal stress to be naturally released so that residual stress is eliminated or reduced. Artificial aging is a human-made method, generally involving heating or freezing treatment to eliminate or reduce micro-stresses within the workpiece after quenching, or residual mechanical processing stresses, to prevent deformation and cracking.

According to the ASM Handbook, three methods can be used to relieve stress.

The first involves using compressive or tensile loads to plastically deform the material in a controlled manner. This method is only suitable for free forgings. The second method involves heat treatment, such as sub-zero treatment or cold stabilization, during which the material is exposed to cyclical temperatures between -73 degrees Celsius and 100 degrees Celsius. This helps reduce internal stress by up to 25%. The final recommended method is to use uphill quenching, where the blank is cooled to -273 degrees Celsius and then quickly heated by hot steam.

In addition, cutting off excess parts in advance, and continuing machining after 1-2 hours of natural aging can also eliminate deformation caused by internal stress.

Aluminum CNC Machining: Improve Workpiece Clamping Methods

If a three-jaw self-centering chuck or collet is used for radial clamping of thin-walled CNC machined bushing parts, once released after machining, the workpiece will undoubtedly deform. Therefore, an axial end-face clamping method with good rigidity should be used. According to the position of the inner hole of the part, a threaded mandrel should be made to find the inner hole of the part. It should be inserted into the inner hole of the part, the end face should be pressed tightly with the cover plate, and the nut should be tightened backward. This prevents the outer circle from loosening and deforming during machining, thus achieving machining accuracy.

For milling thin-walled aluminum parts with poor rigidity, the following clamping methods can be used to improve machining accuracy: use a vacuum chuck to clamp the workpiece to achieve evenly distributed clamping force; another method is to fill the workpiece with liquid medium internally to improve the rigidity of the workpiece, reducing deformation during clamping and cutting. For example, molten urea containing 3% to 6% potassium nitrate can be poured into the workpiece. Alcohol or water can be used to flush the final part to ensure the liquid medium is completely washed away.

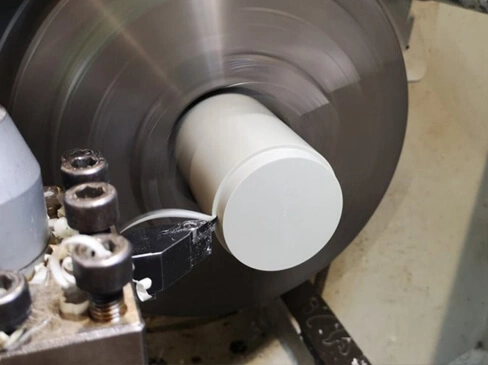

Aluminum CNC Machining: Improve Cutting Performance of Tools

Proper selection of tool parameters directly affects the quality of cutting force and heat dissipation. The material, geometry, and structure of the tool significantly impact cutting performance, and the correct selection of tools is essential to improve dimensional stability.

Tools for processing aluminum alloys should be properly ground for larger back rake and side rake angles. Tools used for finishing should employ larger front rake angles. Additionally, larger front rake angles are also beneficial for machining softer aluminum alloys because they result in sharper cutting edges. Smaller front rake angles are beneficial for rough machining, deep machining, and high feed rates. Front rake angles range from 0 to 40 degrees and should never be negative.

The back rake angle should always be large because it directly affects the wear of the back tool surface and the quality of surface finishing. The back rake angle depends on the feed rate and cutting depth. For rough machining and high feed rates, the back rake angle should be smaller. However, in aluminum CNC machining, it is necessary to reduce elastic deformation and friction between the tool and the workpiece surface to achieve high surface finish. Therefore, the back rake angle should be as large as possible.

Moreover, the clearance angle is also critical for the normal operation of the tool. If the clearance angle is too small, the back (side) of the tool will rub against the workpiece, causing heat dissipation. Conversely, if the clearance angle is too large, the tool will penetrate the workpiece too deeply, causing chatter. Therefore, the optimal clearance angle must be selected. In most applications, the optimal angle is between 6 and 10 degrees.

Finally, to ensure smooth milling and reduce the milling force required for applications, the helix angle should be as large as possible.

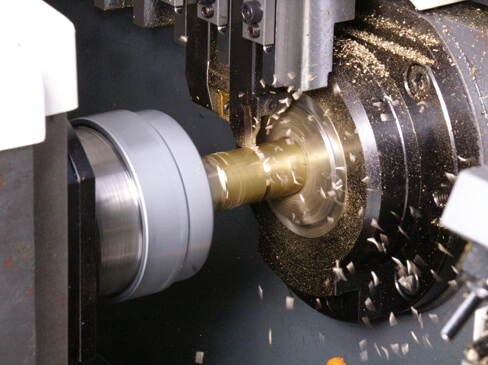

Aluminum CNC Machining: Improve Tool Structure

Reducing the number of milling cutter teeth is important for aluminum machining as aluminum has high plasticity, resulting in significant deformation during machining. Aluminum chips are sticky, affecting the production of finely-toleranced parts. Increasing the spacing between cutting edges allows for the discharge of larger chips.

The roughness of the cutting edge must be maintained below 0.4 µm, and cutting edges should be processed through appropriate grinding operations. This will eliminate all unnecessary burrs, ultimately reducing heat dissipation and cutting deformation.

Tools should be replaced or refurbished according to standards. Therefore, when surface roughness values exceed 0.2 mm and cutting temperature values exceed 100 degrees Celsius, tools must be replaced or supplemented.

Aluminum CNC Machining: Use Appropriate Operating Methods

Choose the right feed rate, spindle speed, and cutting depth; use symmetrical machining methods on both sides of the workpiece to avoid concentrated machining which is not conducive to heat dissipation;

Use layered multiple machining methods for all cavities of the workpiece to make the force on the part uniform and reduce deformation;

In the machining of deep-cavity parts, use the method of drilling before milling to avoid poor chip removal, causing workpiece overheating, tool breakage, and chipping.

Reasonably arrange the machining process; the CNC high-speed cutting process generally includes: rough machining - semi-finish machining - clear corner machining - finish machining. For parts with high precision requirements, increase the frequency of semi-finish machining and maintain uniform machining allowance.

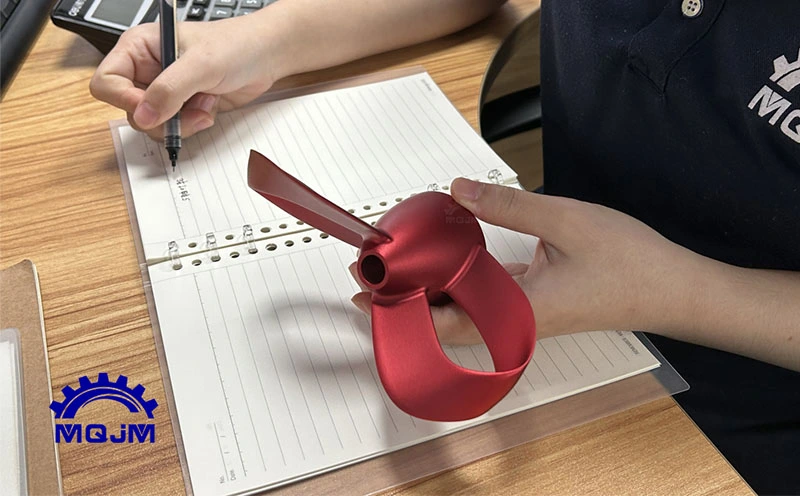

MQJM has been focusing on custom aluminum CNC machining services for 13 years, continuously pioneering and advancing in the field of aluminum CNC machining. Whether you need machined aluminum prototypes or custom aluminum parts for automotive, aerospace applications, or medical device components, we can easily assist you. Leveraging MQJM's expertise in aluminum CNC machining and its ability to integrate external combination processes, we can ensure your aluminum CNC machining project achieves optimal performance.