MQJM has extensive experience in customizing wireless charger housings, ensuring high quality and precision in every project. Our expertise in CNC machining allows us to deliver products that meet our clients' exact specifications and aesthetic requirements. Over the years, we have worked on numerous custom projects, honing our skills and perfecting our processes to produce superior wireless charger housings.

For CNC machining 6061 aluminum wireless charger housings, several surface treatment options are suitable:

1. Anodizing:

Process: Forms a thick oxide layer on the aluminum surface through an electrochemical reaction.

Advantages:

1)Enhances corrosion resistance and wear resistance.

2)Offers various color options, enhancing aesthetics.

3)Does not affect electrical conductivity (suitable for electronic products).

Suitable Scenarios: Ideal for wireless charger housings used in outdoor and humid environments.

2. Powder Coating or Liquid Coating:

Process: Applies powder or liquid paint uniformly on the aluminum surface, then cures it through heating.

Advantages:

1)Provides a wide range of colors and surface effects.

2)Offers good corrosion resistance and weather resistance.

3)High surface hardness and scratch resistance.

Suitable Scenarios: Suitable for products with high aesthetic requirements.

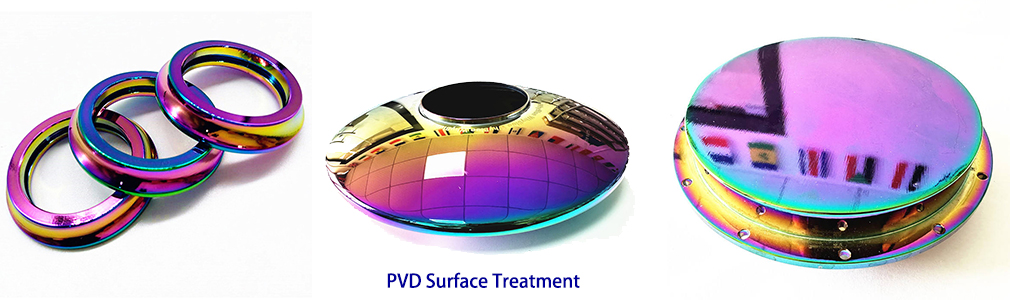

3. Electroplating:

Process: Uses electrochemical reactions to plate a layer of metal, such as nickel or chrome, on the aluminum surface.

Advantages:

1)Enhances surface gloss and aesthetics.

2)Provides some corrosion protection.

Suitable Scenarios: Suitable for wireless charger housings requiring both appearance and corrosion resistance.

4. Mechanical Polishing:

Process: Utilizes mechanical methods (such as sanding and polishing) to treat the aluminum surface.

Advantages:

1)Achieves a smooth, shiny surface.

2)Enhances the product's appearance and feel.

Suitable Scenarios: Ideal for high-end products that emphasize visual effects.

5. Chemical Plating:

Process: Uses chemical reactions to deposit a layer of metal plating on the aluminum surface.

Advantages

1)Improves corrosion resistance and surface hardness.

2)Forms a uniform plating layer, suitable for complex-shaped cnc parts.

Suitable Scenarios: Suitable for products with specific requirements for corrosion resistance and appearance.

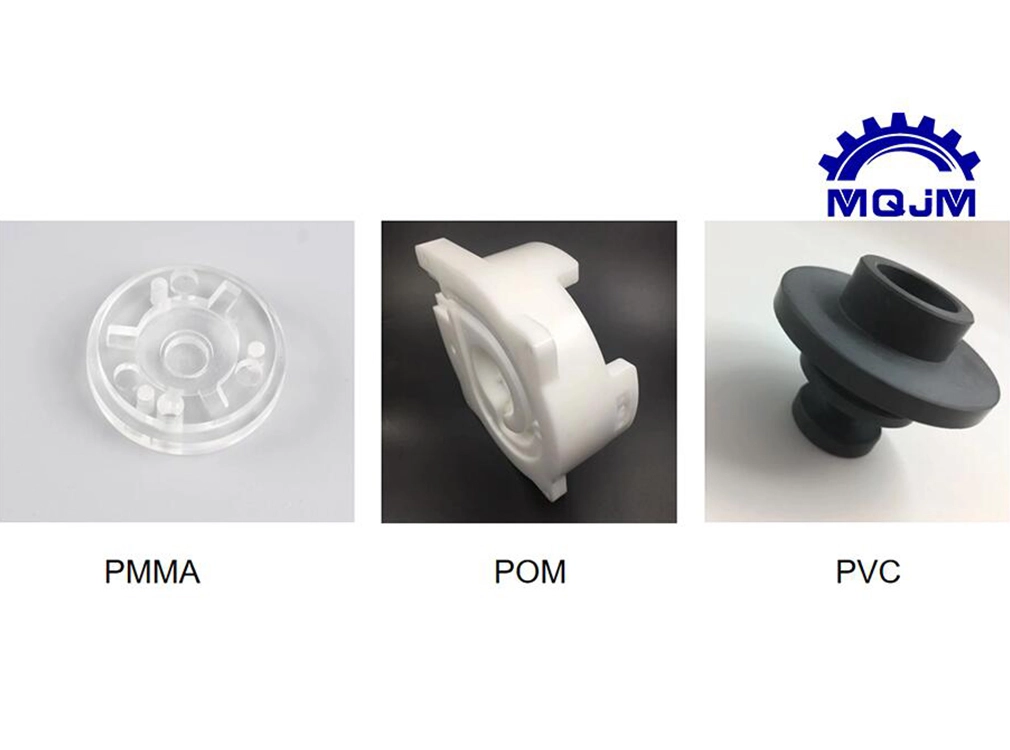

Choosing the appropriate surface treatment method involves considering factors like the product's usage environment, aesthetic requirements, and cost. Based on specific needs, MQJM can provide professional cnc machining advice and solutions for customers.