Customer Inquiry and Initial Communication

Recently, a customer inquired if MQJM could produce CNC knobs with CD textures. Confidently, we assured the customer that MQJM not only possesses this capability but also has extensive experience in this area.

MQJM's Professional Background

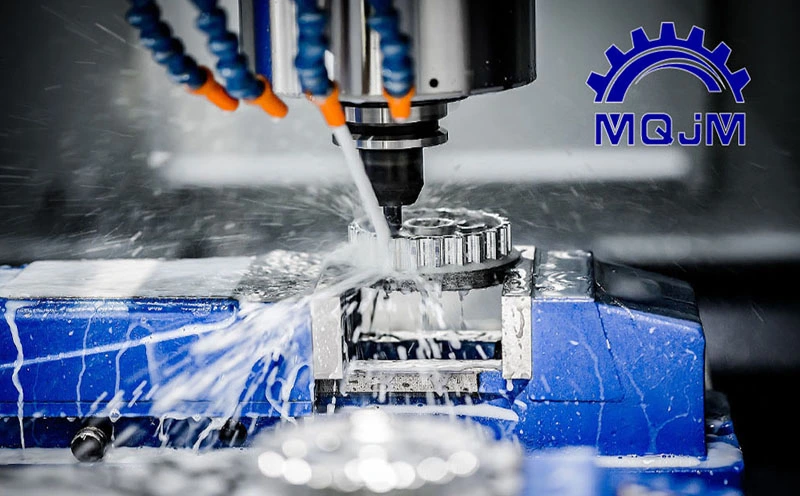

Since its establishment in 2010, MQJM has specialized in CNC machining for over 13 years. Our factory, located in Guangming District, Shenzhen, China, is equipped with multiple advanced CNC machining machines, including cnc lathes and cnc milling machines. These machines enable us to handle various complex machining requirements and ensure high precision and quality in our machined products.

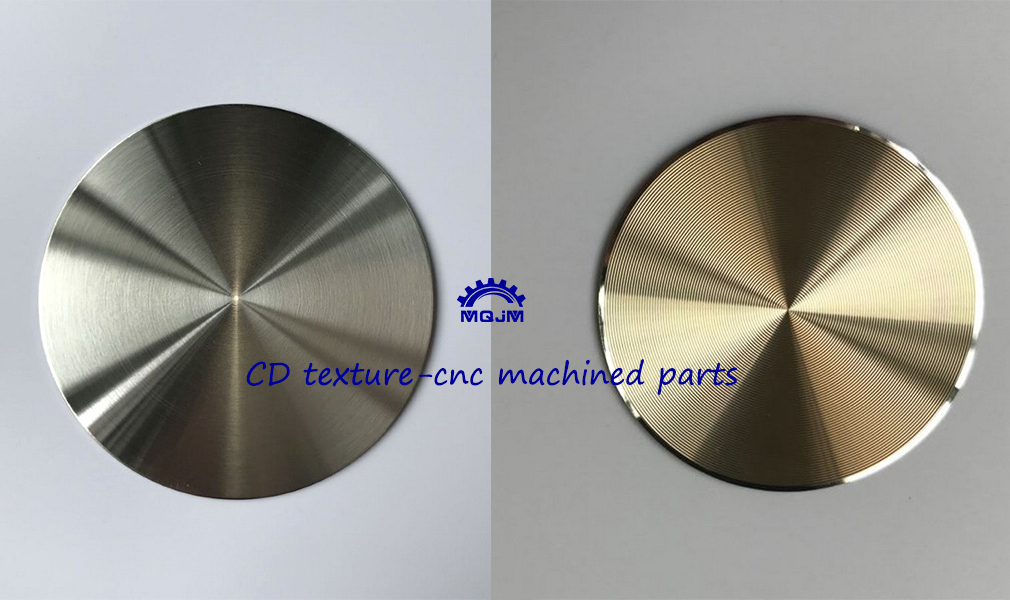

CD Texture Machining Process and Quality

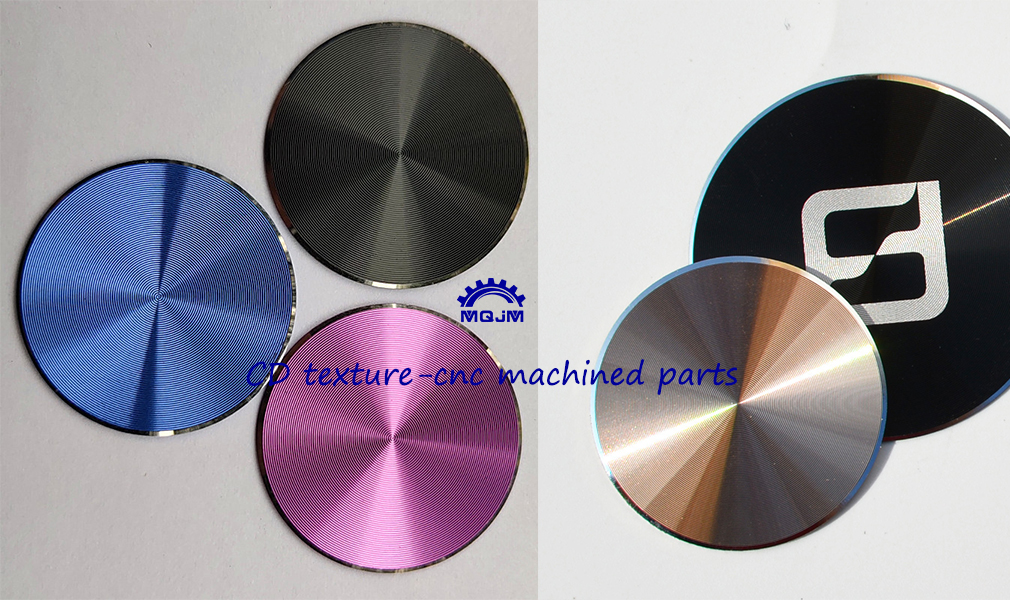

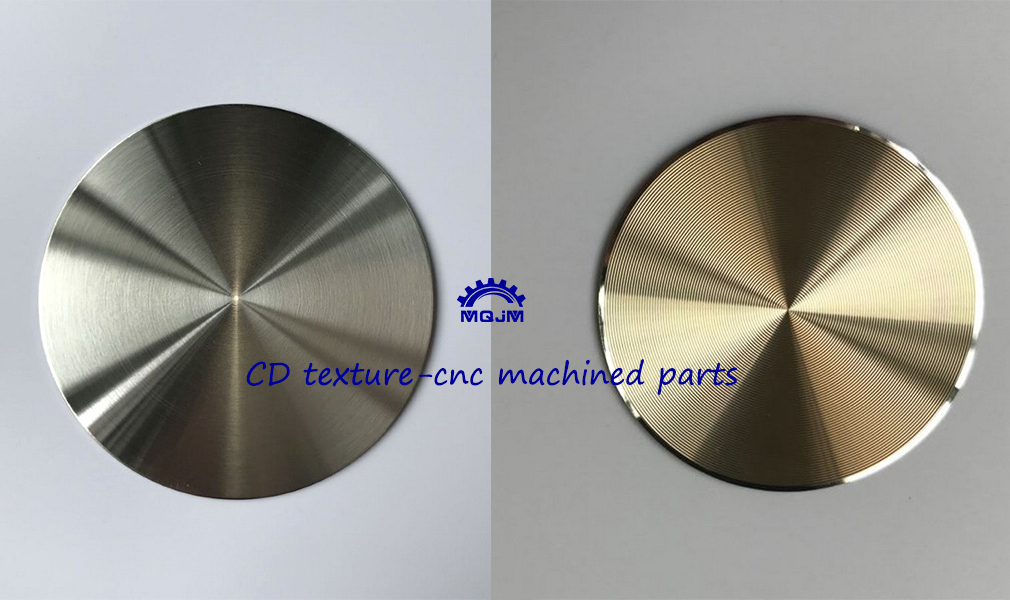

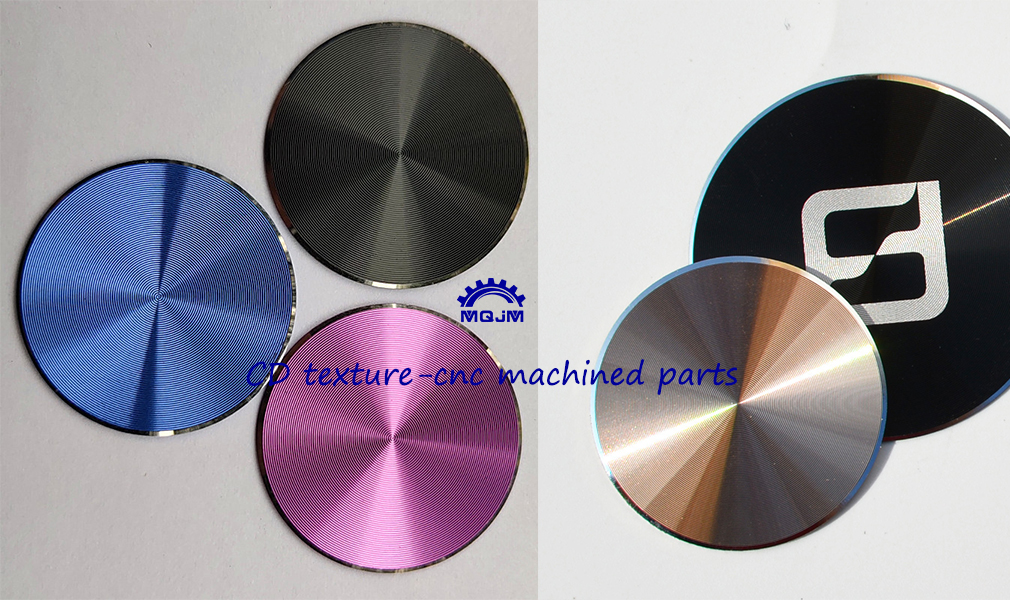

To demonstrate our capabilities, we showcased some previously produced CD textured parts. CD textures are circular patterns formed on metal surfaces through rotary machining. These patterns are not only aesthetically pleasing but also enhance grip and friction. Utilizing precise CNC technology during the machining process, we ensure that the spacing and depth of each CD texture meet customer specifications. Through high-precision control, we produce knobs with uniform, smooth, and high-quality CD textures.

Various Surface Treatment Services for CNC Machining Parts

In addition to CD texture machining, we offer a variety of other surface treatment services, such as high-gloss edge and knurling treatments. High-gloss edge treatment makes the edges of the parts smooth and shiny, while knurling treatment increases friction by engraving fine patterns on the surface. These treatments not only enhance the appearance of the parts but also improve their functionality.

Reaching Cooperation with the Customer

After thoroughly understanding our CNC machining capabilities and past successful cases, the customer decided to collaborate with us. They requested us to produce samples first to check the product quality. We promptly initiated the sampling process, ensuring the provided samples fully meet the customer's expectations.

Through this collaboration, MQJM once again demonstrated our professional level in CNC machining and high standards of customer service. We look forward to working with more customers in the future to develop more high-quality CNC machined parts together.