In modern manufacturing, Computer Numerical Control (CNC) machining technology has become an indispensable aspect. Utilizing precision machines controlled by computers, it efficiently cuts, shapes, and processes various materials including metals, plastics, and woods. This article delves into the different types and features of CNC machining, while also introducing MQJM as a highly experienced CNC service factory.

Types of CNC Machining

CNC machining encompasses various types, each with its unique method and application.

Milling: Utilizes rotating cutters to remove material from the workpiece surface, commonly used for creating flat surfaces, protrusions, and recesses.

Drilling: Creates holes or slots on the workpiece using rotating drill bits.

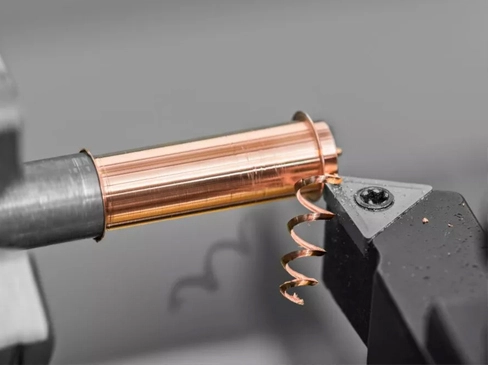

Turning: The workpiece is fixed on a rotating spindle, and the tool removes material as it moves across the workpiece, suitable for producing rotationally symmetric parts like shafts.

Grinding: Utilizes grinding wheels to remove material to achieve higher surface quality and precision.

Electrical Discharge Machining (EDM): Material is removed from the workpiece by applying high-voltage pulses between the workpiece and electrode, often used for processing hard and difficult-to-machine materials.

Laser Cutting: Cuts materials into desired shapes using a laser beam, suitable for both metals and non-metals.

Features of CNC Machining

CNC machining is renowned for its unique characteristics, revolutionizing the manufacturing industry.

Automation: CNC systems automatically execute pre-programmed machining operations, reducing manual intervention and enhancing production efficiency.

Precision: With precise control of CNC systems, high-precision machining can be achieved, ensuring product quality and accuracy.

Flexibility: Machining processes can be quickly altered through reprogramming or tool changes to adapt to different product requirements.

Mass Production: CNC systems are suitable for large-scale production, improving production efficiency and consistency.

Complexity: CNC systems can handle various complex shapes, including curves, surfaces, and three-dimensional structures.

Traceability: Parameters and operations during CNC machining can be recorded, facilitating quality control and issue identification.

Time and Cost Savings: Compared to traditional manual machining, CNC machining is typically faster and more precise, reducing labor costs and machining time.

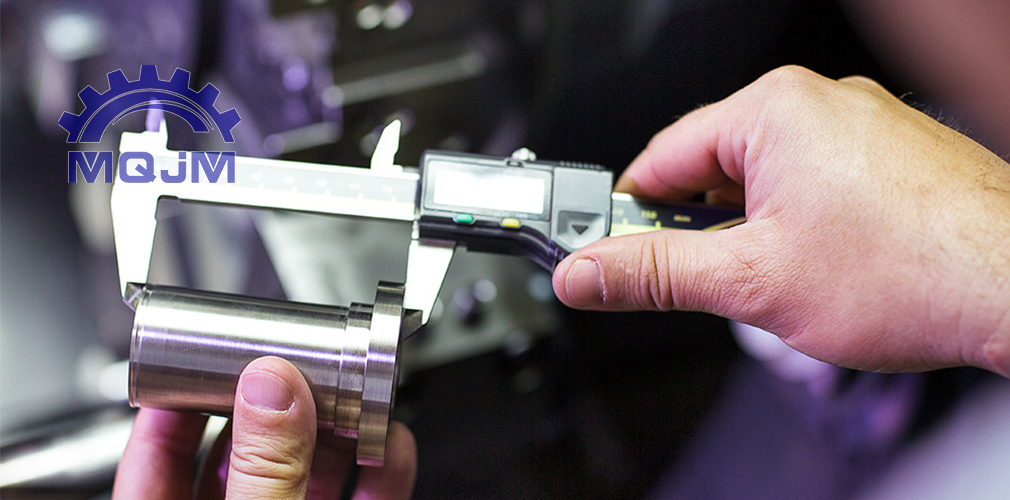

MQJM is a leading enterprise with 13 years of experience in CNC machining, offering professional services and advanced facilities.

Rich Experience: MQJM Factory boasts extensive experience in CNC machining, catering to diverse customer needs.

High-Quality Equipment: With over 60 CNC machining devices, including milling machines, lathes, and laser cutting machines, the factory provides comprehensive production services.

Independent Testing Department: MQJM Factory has a dedicated testing department, committed to ensuring product quality and precision.

Technical Support: The factory has a professional technical team capable of providing technical support and consultation services to customers.

In conclusion, CNC machining technology, with its diverse types and unique features, plays a crucial role in modern manufacturing. MQJM, as a CNC facility with rich experience and expertise, is dedicated to providing high-quality and diversified CNC machining services, becoming a trusted partner for customer success.