Engraving a logo on CNC machined parts not only enhances brand image but also increases CNC product recognition and professionalism. Selecting the appropriate logo engraving method is crucial, as it impacts the logo's appearance, durability, production cost, and efficiency. This article will detail several common logo engraving methods, including laser engraving and CNC machining, and discuss their pros and cons to help businesses make an informed choice.

I. Laser Engraving for CNC Machined Parts

Principle:

Laser engraving uses a laser beam to ablate the material's surface at high temperatures, creating a permanent mark.

Advantages:

1. High Precision: Laser engraving can achieve very fine details and intricate patterns.

2. Durability: The engraved logo is resistant to wear and corrosion and does not fade easily.

3. Non-contact Process: It does not apply mechanical stress or damage to the part, making it suitable for various materials.

Disadvantages:

1. Higher Cost: The initial investment in laser equipment is relatively high, especially for high-power lasers.

2. Slower Speed: For mass production, laser engraving might be slower.

Suitable Scenarios:

Ideal for parts requiring high precision and durability, such as electronic components, medical devices, and high-end mechanical parts.

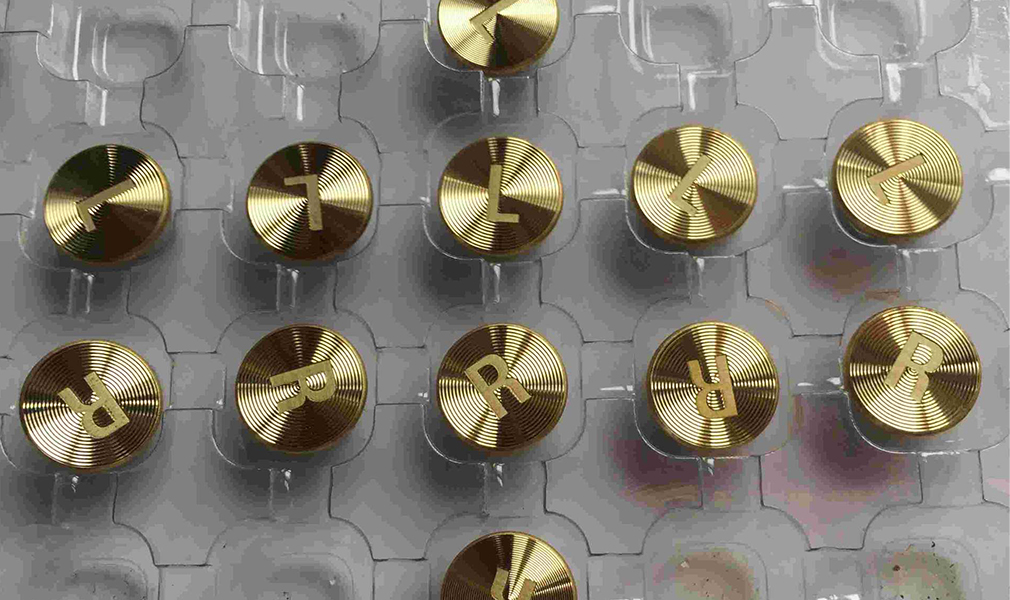

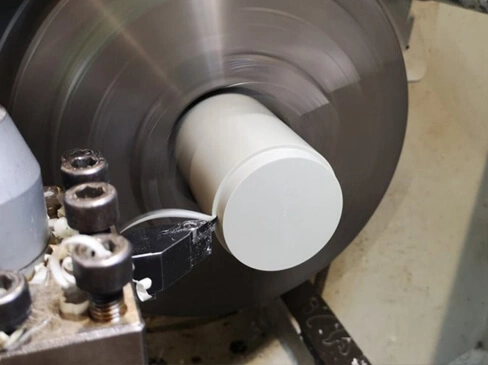

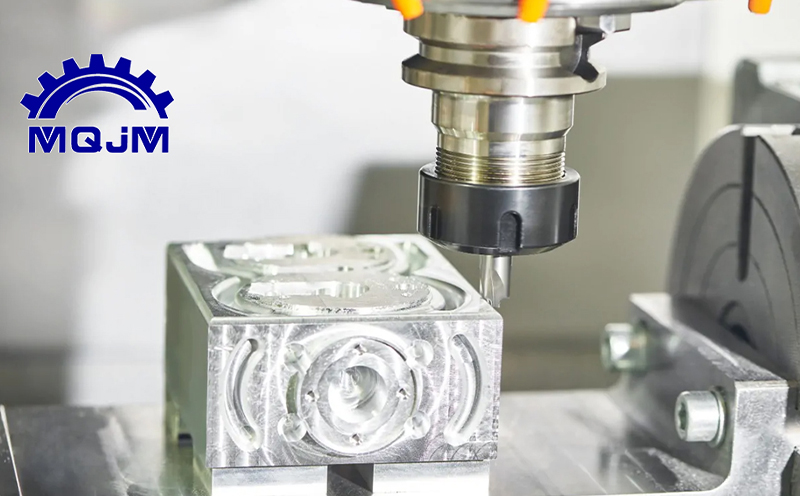

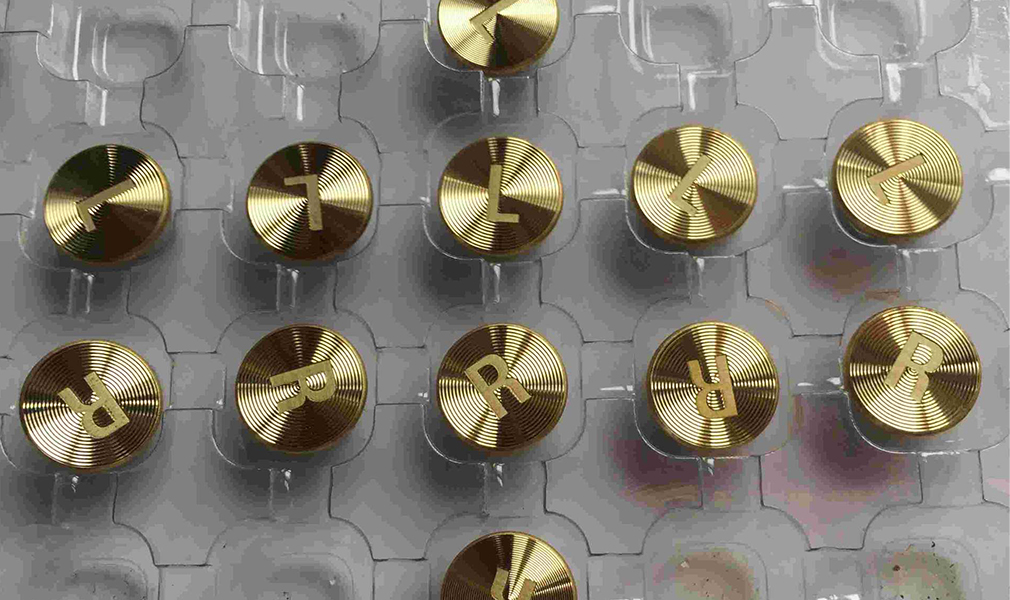

II. CNC Machining

Principle:

CNC machining uses machine tools to mechanically engrave the logo on the part's surface.

Advantages:

1. High Precision: CNC machining can achieve high-precision logo engraving.

2. Versatile Materials: Suitable for a wide range of materials, including metals and plastics.

3. Integrated Production: The logo can be engraved during the part machining process, saving time and cost.

Disadvantages:

1. Surface Requirements: The part surface must be smooth to ensure quality engraving.

2. Tool Wear: Prolonged use can lead to tool wear, requiring regular replacement.

Suitable Scenarios:

Ideal for mechanical parts, metal products, and items requiring high-precision logo engraving.

Conclusion

When engraving a logo on CNC machined parts, choosing the right method involves considering factors such as material properties, precision requirements, durability, and cost. Laser engraving is suitable for parts requiring high precision and durability, while CNC machining is ideal for integrated production and high-precision metal parts. By selecting the appropriate precision cnc services, businesses can enhance their product's brand image and market competitiveness.