In the aerospace industry, the quality and precision of parts are of utmost importance. Aircraft components demand extremely high standards, making **precision CNC machining** essential. With years of expertise and advanced equipment, MQJM has provided reliable machining services to various aerospace clients. From high-tolerance aluminum parts to durable plastic housings, MQJM meets the specialized needs of aerospace manufacturing. This article delves into how MQJM uses **precision CNC aerospace machining** to produce components that meet stringent aerospace requirements.

1. High-Tolerance 7075 Aerospace Aluminum CNC Milled Part

Aerospace parts require exceptionally tight tolerances, especially in critical areas. One of our clients specified 7075 aerospace aluminum for production, with certain areas requiring tolerances as tight as ±0.005mm. Using 5-axis CNC machinery for precision CNC aerospace machining, MQJM ensured the necessary precision for this part. By fully understanding the client’s requirements during the programming and fixture design stages, we minimized production errors, achieving a remarkable 98.7% yield rate. This part also features an anti-oxidation anodized layer, controlled between 10-20 microns, enhancing surface protection and durability in harsh aerospace environments.

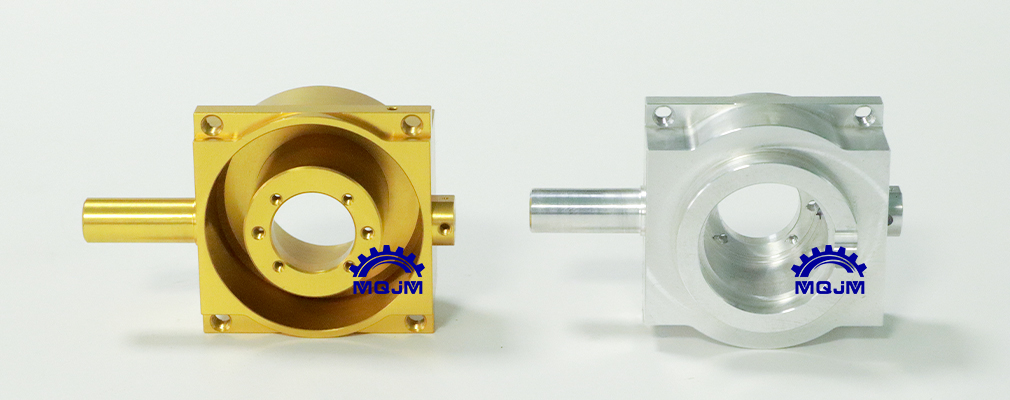

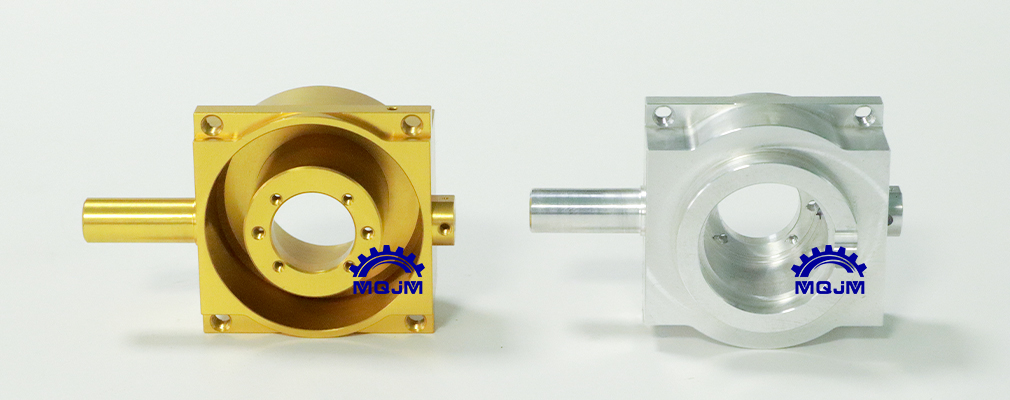

2. Small Aircraft Component: Anodized Gold Aluminum Part

This component, crafted from 6061 T6 aluminum, was anodized in gold and designed for use in small aircraft. The middle section requires precise thickness control to fit tightly with other aircraft parts. Our engineering team overcame challenges in controlling the middle circular section’s thickness by using a two-step process: rough machining followed by fine machining. This approach, though time-intensive, allowed us to meet the client’s precise specifications, ensuring the part’s compatibility with aerospace standards.

3. Lightweight POM Plastic Housing for Commercial Aircraft

In addition to metal parts, MQJM manufactures plastic components for aircraft. This black POM plastic housing, designed for commercial aircraft, required high precision CNC machining services to ensure accurate dimensions. POM material offers high strength, excellent wear resistance, and heat resistance, meeting the stringent requirements for aerospace use. We measured all dimensions of the part using coordinate measuring equipment and provided the client with detailed material and inspection reports. The client was very satisfied with the testing results and proceeded with a bulk order.

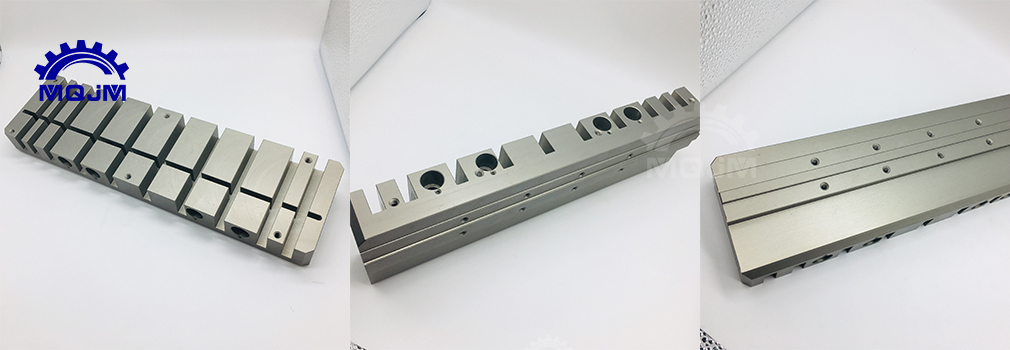

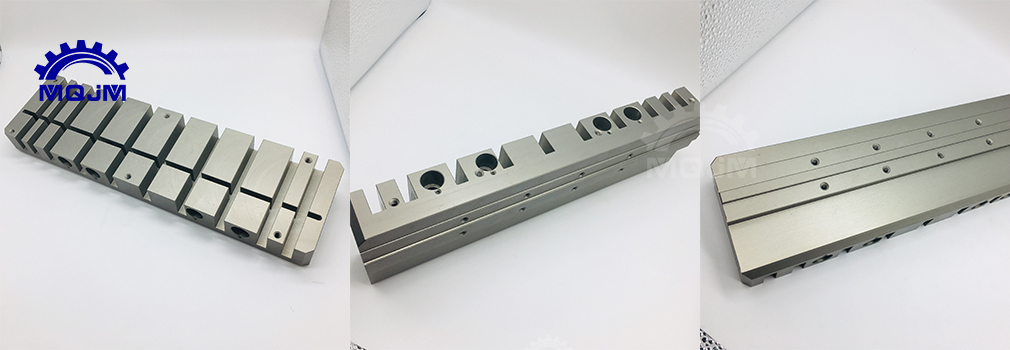

4. 7075 Aluminum Hard-Anodized Silver CNC Milled Part

7075 aluminum is ideal for aerospace components due to its superior properties. We manufactured a small component (60*15*10cm) for a U.S. client using 7075 aluminum, utilizing 4-axis aluminum CNC milling service for production. The surface underwent hard anodizing in silver, enhancing durability in high-stress environments. Despite its small size, this part meets stringent aerospace standards for precision and corrosion resistance.

With extensive experience in aerospace precision machining, MQJM provides top-notch solutions for aerospace clients. Through high-precision CNC machining and a skilled technical team, MQJM consistently delivers precision aerospace products that meet the demanding standards of the aerospace industry. From complex aluminum parts to high-performance plastic housings, MQJM is dedicated to helping clients achieve their aerospace goals with superior quality and reliability.