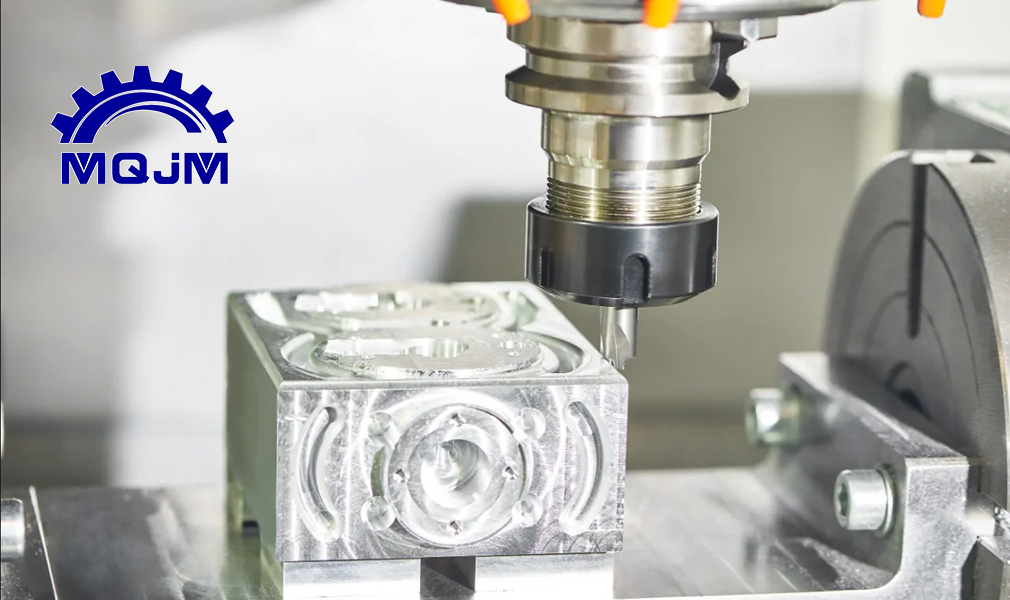

CNC machining is one of the key technologies in modern manufacturing, using computer numerical control (CNC) technology to achieve high-precision machining of various materials. Compared to traditional manual operations or mechanically driven machining methods, CNC machining has many advantages.

Firstly, CNC machining features a high degree of automation. Through pre-written CNC programs, operators only need to set machining parameters and load the workpiece, and the machine tool can automatically complete the machining process. This automated machining method not only saves labor costs but also improves machining efficiency.

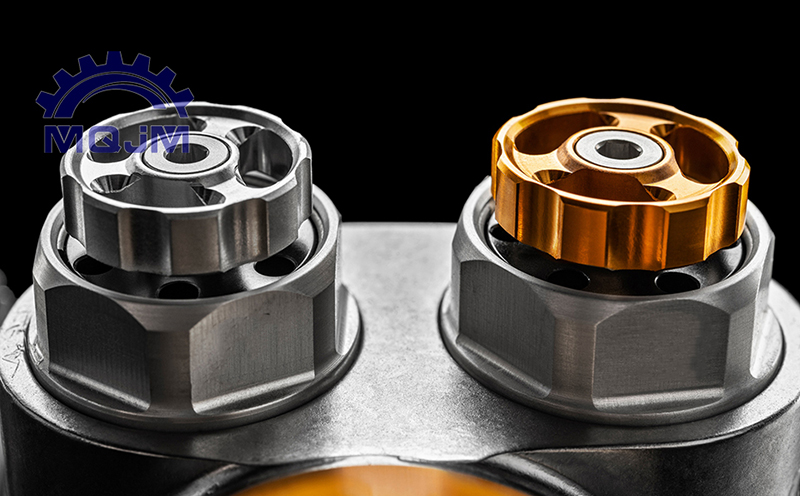

Secondly, CNC machining offers higher machining accuracy. Because the machining paths and parameters are controlled by the computer, CNC machine tools can execute machining operations more precisely, achieving precise control over the dimensions, shapes, and surface quality of the workpiece. This makes CNC machining widely used in industries with high precision requirements, such as aerospace and automotive manufacturing.

Additionally, CNC machining also demonstrates good repeatability and stability. Once a CNC program is well-written, the same workpiece can be machined repeatedly without deviation, ensuring consistency in machining results. This is particularly important for large-scale production and batch machining.

MQJM specializes in providing CNC machining services. With extensive experience and advanced equipment, we have successfully completed over 3000 CNC teaching tool parts. If you have any CNC machining needs, please feel free to contact us, and we will provide you with high-quality machining solutions and attentive service.