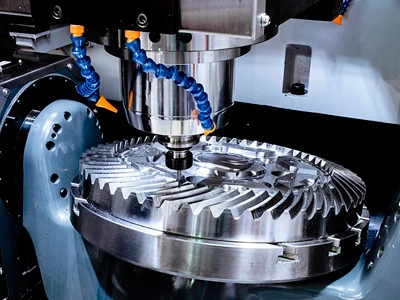

Why Choose Aluminum Material for Aluminum CNC Machining?

Aluminum material, as one of the most commonly used materials in the current field of machining, has such a wide range of applications and superior performance that aluminum CNC machining technology has become an indispensable part of modern manufacturing. The reason aluminum is favored so much is not only because of its excellent properties in its pure aluminum form but also due to the diverse and outstanding properties it exhibits after alloying treatment.

Detailed Advantages of Aluminum CNC Machining

Excellent Machinability

In various machining processes, aluminum exhibits extremely high adaptability, whether it is cutting, milling, or drilling, it can be completed quickly and accurately. Its characteristic of being soft and ductile makes aluminum easy to form under CNC machine tools, greatly improving production efficiency and processing precision.

Outstanding Specific Strength

The density of aluminum is far lower than that of steel, only about one-third of steel, which allows aluminum to achieve significant weight reduction while maintaining high strength. This unique specific strength characteristic makes aluminum the preferred material for lightweight designs in industries such as aerospace, automotive manufacturing, and electronic equipment.

Excellent Corrosion Resistance

In natural environments, especially in marine and atmospheric environments, aluminum exhibits good corrosion resistance. Through anodizing treatment, a dense oxide film can form on the surface of aluminum, further enhancing its corrosion resistance and extending its service life.

Stability at Low Temperatures

Even under very low temperature conditions, aluminum can still maintain its good softness, ductility, and strength, which makes aluminum have unique application value in low-temperature engineering and refrigeration equipment fields.

Excellent Electrical Conductivity

Pure aluminum has excellent electrical conductivity, with a conductivity of up to 37.7 million siemens per meter at room temperature. Although the electrical conductivity of aluminum alloys is slightly inferior to pure aluminum, it still meets the application scenarios requiring high electrical conductivity, such as electronic components.

High Recyclability

Aluminum waste generated during CNC machining can be reused after simple processing due to the high recyclability of aluminum. This process not only reduces resource waste but also lowers production costs, aligning with the concept of green and sustainable development in modern industry.

Diverse Applications of Anodizing

Anodizing technology not only enhances the surface hardness and corrosion resistance of aluminum but also provides a rich selection of colors for aluminum parts. This technology allows aluminum to showcase unique artistic appeal and practical value in fields such as architectural decoration and artwork production.

In summary, aluminum CNC machining has occupied a significant position in the manufacturing industry due to its numerous advantages. With continuous technological advancements and expanding applications, aluminum CNC machining is bound to play an important role in more fields, promoting the development of modern manufacturing towards higher efficiency, environmental friendliness, and greater intelligence.