Materials and Features of CNC Bicycle Parts

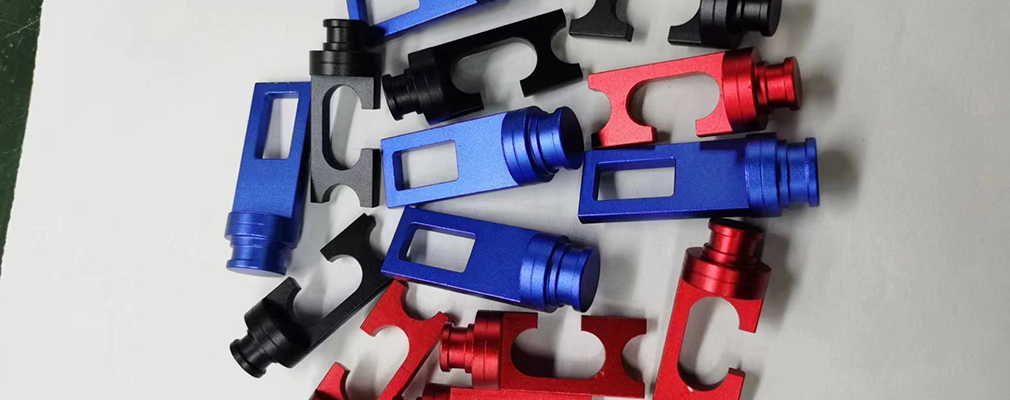

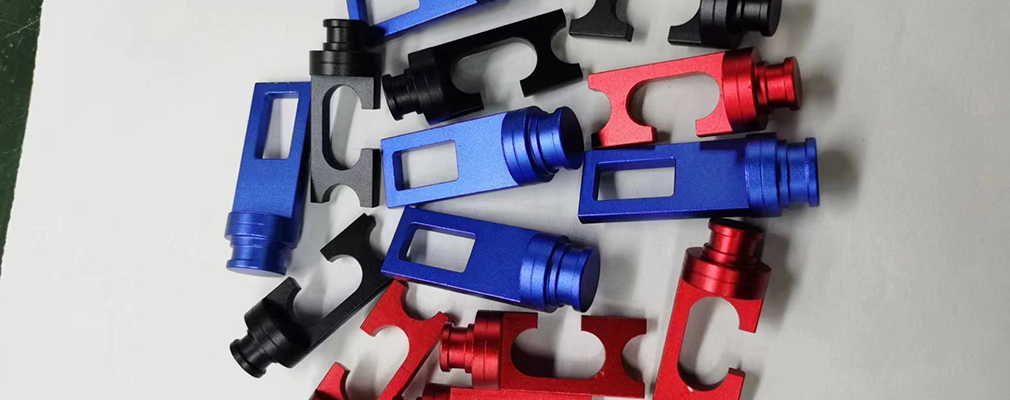

CNC Bicycle parts come in a wide variety, ranging from riding gear to professional accessories, each with unique requirements for strength, lightweight design, and aesthetics. Common parts include top caps, light mounts, bicycle grips, bicycle spacers, bar end plugs, chain keeper*, bicycle headsets, bottom brackets, valve stem caps, and bicycle clamps.

Aluminum (especially 6061 and 7075 alloys) is a popular choice for parts like headsets and handlebars due to its lightweight and corrosion-resistant properties. Stainless steel, on the other hand, is often used for critical load-bearing components like cranks, thanks to its high strength and wear resistance. Additionally, brass parts are favored for high-end bicycle modifications because of their excellent oxidation resistance and decorative appeal.

The manufacturing process mainly involves CNC turning and milling, complemented by surface treatments such as anodizing and plating, ensuring the parts meet both functional requirements and the aesthetic preferences of cycling enthusiasts.

Examples of CNC Bicycle Parts Machined by MQJM

1. Aluminum Headset Tubes

MQJM recently delivered 200 custom aluminum headset tubes to a client in Australia. Made from 6061 aluminum, these parts underwent anodizing for a shiny surface finish as per the client’s request, skipping the sandblasting process. This client, who has been working with MQJM for over three years, has also ordered other parts such as brake levers, aluminum spacers, and handlebars. This long-term partnership highlights MQJM’s commitment to quality and service.

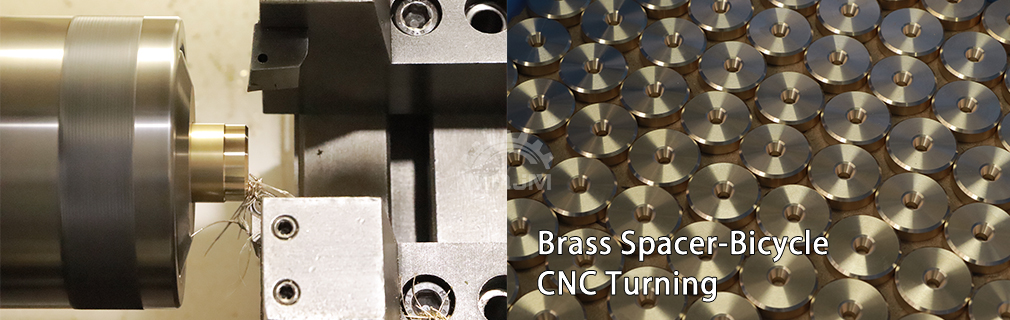

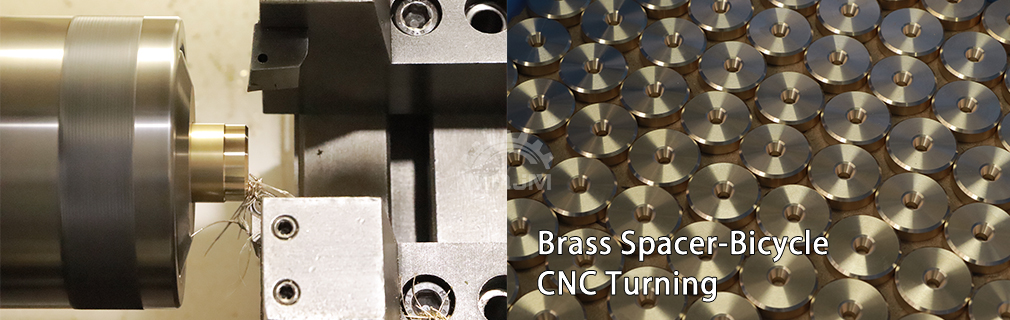

2. Custom Brass Spacer

We have produced numerous custom brass washers for bicycle and mountain bike modifications. These small CNC-turned parts are often ordered in batches of thousands or even tens of thousands. Some clients also request additional services, such as attaching plastic rings to the washers. With 20 CNC turning machines, MQJM efficiently handles large-volume orders while maintaining excellent attention to detail.

3. Aluminum Cranks

Cranks are essential components of a bicycle’s drivetrain, typically made from aluminum alloy or stainless steel. While their structure is relatively simple, they require high precision and strength. MQJM’s aluminum cranks meet the stringent quality standards of the bicycle industry, balancing lightweight design with durability, earning the trust of our clients.

4. Aluminum Valve Stem Caps

As small yet impactful decorative components, aluminum valve stem caps enhance the overall appearance of bicycles. MQJM has established a long-term partnership with a mountain bike equipment company in central Italy. They frequently send samples, and MQJM manufactures custom CNC parts based on their specific ideas and designs.

Global Demand for CNC Bicycle Parts

The leading countries for CNC bicycle parts demand include the USA, Germany, Italy, Japan, and the Netherlands. Customers in these countries often seek highly customized parts, particularly in Italy, where a deep cycling culture drives demand for premium modification components like precision-anodized mountain bike parts and aluminum decorative accessories. With extensive experience and excellent service, MQJM has built stable partnerships with clients worldwide.

Conclusion and Call to Action

With years of expertise in high precision CNC machining services for CNC bicycle parts, MQJM provides custom, high-quality solutions tailored to your needs. Whether you require CNC bicycle parts, mountain bike CNC machined components, or other riding gear, MQJM is your ideal partner. Our team is professional, service-oriented, and delivers superior products at competitive prices.

Visit www.mqjmcnc.com (http://www.mqjmcnc.com) to explore more custom cases and experience MQJM's exceptional quality and service.