Definition of High Precision CNC Milling

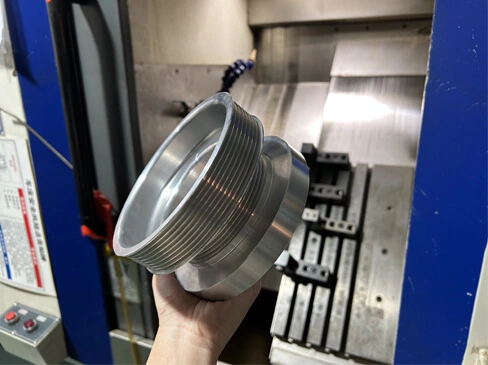

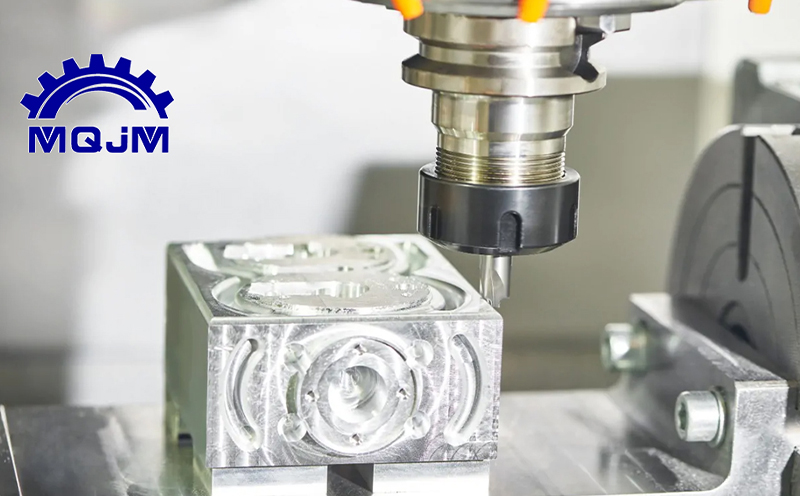

High precision CNC milling is a manufacturing process that uses computer-controlled machines to remove material from a workpiece. The process involves using a rotating cutting tool to cut out the desired shape from a solid block of material.

Milling machines are highly precise and capable of producing workpieces with complex shapes. They can also be programmed to produce multiple identical parts, making the milling process a cost-effective production solution.

Applications of High Precision CNC Milling

Medical

High precision CNC milling is used to manufacture parts for the healthcare and medical sectors, such as orthopedic implants and surgical instruments.

Electronics

Electronic hardware, housings, metal strips, panels, engraved parts, and other electronic components are all made using high precision CNC milling.

Military

High precision CNC milling can be used to produce CNC-milled parts for aircraft, vehicles, and weapons.

Aerospace

Aircraft components require high precision CNC milling services to manufacture parts such as aircraft engines, gearboxes, hydraulic manifolds, landing gear, electrical connectors, housings, and more.

Automotive

High precision CNC milling is used to manufacture custom automotive parts, including engine components, battery housings, and interior parts, all of which require CNC-milled parts.

Food

High precision CNC milling technology is used to design components for food processing machinery, mixers, grinders, pulverizers, and cleaning equipment.

Machinery

The machine tool industry requires parts such as fasteners, fittings, shafts, hydraulic and machine components, all of which are designed using high precision CNC milling technology.

Advantages of Aluminum CNC Milling Services

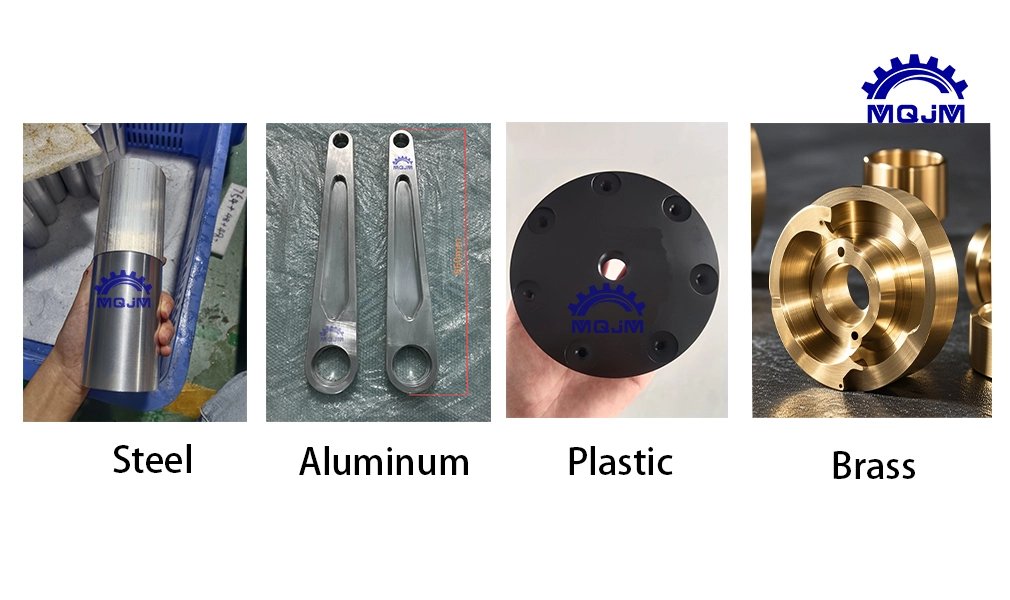

Parts processed with aluminum CNC milling service have high dimensional stability, high machining accuracy, and high repeatability.

Aluminum CNC milling services are among the most versatile CNC machining processes, with strong adaptability and flexibility for part processing.

Aluminum CNC milling parts can undergo multiple operations after a single setup and positioning.

Aluminum CNC milling services can process parts with complex contour shapes or strict dimensional tolerances, such as mold parts, housing parts, etc.

Aluminum CNC milling services from reliable custom cnc precision machining suppliers have a high degree of automation, high production efficiency, and can run continuously 24 hours a day, facilitating automated production management.