MQJM CNC Machining Shop has over 14 years of experience in CNC precision machining and is equipped with more than 60 advanced CNC machining centers. We specialize in CNC turning, CNC milling, and 5-axis CNC machining, particularly in the customization of racing, automotive, and motorcycle components. In this article, we’ll detail some of the custom CNC parts we’ve successfully manufactured, showcasing our capabilities in the automotive CNC machining field.

1. Custom CNC Machined Oil Cap

The oil cap is a critical component that protects the engine and fuel system. It not only needs to ensure a secure seal but also must function reliably under extreme conditions. Common materials used for oil caps include aluminum and stainless steel, known for their excellent corrosion resistance and pressure durability.

In the customization of oil caps, MQJM employs CNC precision machining techniques to achieve high-accuracy threading and sealing groove machining, ensuring a perfect fit with the fuel tank. Clients can also choose from various surface treatments, such as anodizing or polishing, to enhance both durability and aesthetics. Additionally, many clients request branding options, such as engraved logos, to personalize their oil caps. Our customization services ensure that oil caps meet functional requirements while enhancing the overall style of racing and automotive applications.

2. Custom CNC Machined Caliper Adapter

Caliper adapters are vital components in racing and high-performance vehicles, responsible for securing the brake caliper in place to ensure precise alignment with the rotor, thus providing optimal braking performance. CNC precision machining is crucial in producing caliper adapters, as the size and tolerances directly impact the performance of the entire braking system.

Typically made from aluminum or high-strength steel, these materials are both lightweight and robust, capable of withstanding the enormous forces generated during heavy braking. Using CNC milling technology, we ensure that every caliper adapter meets stringent size and tolerance specifications, allowing for reliable performance even under high-speed and high-temperature conditions.

Moreover, many racers and custom car owners often require multiple types of caliper adapters for different vehicles or track conditions. Therefore, MQJM provides a unique part numbering system for easy identification of each adapter, enhancing usability and simplifying maintenance and upgrades for our clients.

3. Custom CNC Machined Rotor Hat

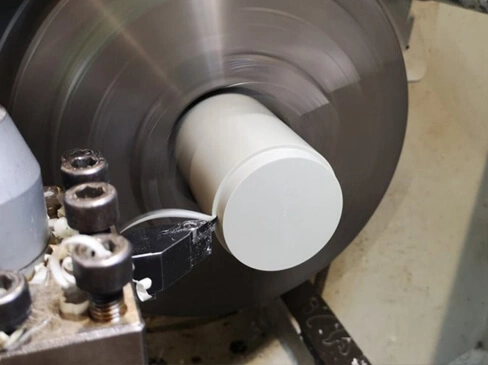

The rotor hat is another critical component of a high-performance braking system, typically paired with the caliper adapter. It must not only provide a stable connection to the brake rotor but also withstand the high centrifugal forces and extreme temperatures associated with racing. Consequently, the material and machining precision of the rotor hat are of utmost importance.

We commonly use high-strength aluminum or specialized steel for machining rotor hats, ensuring they can perform reliably in demanding racing environments. MQJM employs CNC milling and turning techniques to achieve tolerances within ±0.01mm, as stringent tolerance control ensures that the rotor hat remains balanced at high speeds, avoiding unnecessary vibrations or wear.

The design of the rotor hat must also perfectly fit the braking system. We often optimize the cooling design to meet client requirements, enhancing corrosion resistance through various surface treatments. Additionally, customers can customize the color and texture of the rotor hat’s surface, aligning it with the overall aesthetic of their vehicle, thereby enhancing both functionality and appearance.

4. Custom CNC Machined Shift Knob

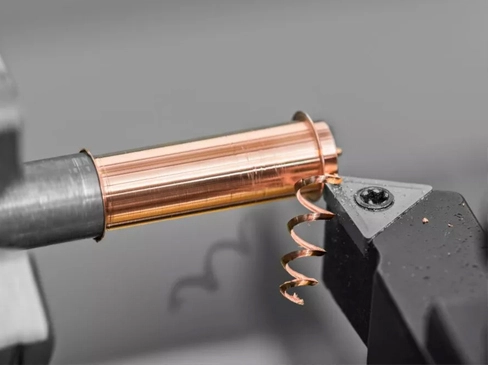

Shift knobs are not only frequently used components but also important parts of a vehicle's interior design. The comfort and aesthetics of a shift knob directly impact the driving experience. Typically made from aluminum, stainless steel, or high-performance plastics, shift knobs are primarily produced using CNC turning processes to achieve precise shapes and dimensions.

At MQJM, we use CNC turning technology to ensure the symmetry and accuracy of shift knobs. After the primary machining process, clients can select from various surface treatments, such as anodizing, plating, or painting, to enhance aesthetics and durability. We also provide custom engraving and logo design services, allowing each shift knob to be a unique piece.

Some customers prefer adding special textures or patterns to the shift knobs to improve grip and tactile feel, enhancing control precision. Racers and performance car enthusiasts often favor lightweight materials, making aluminum and carbon fiber shift knobs particularly popular. MQJM focuses on every detail of the machining quality while striving to provide personalized customization experiences that meet the needs of different vehicles and driving styles.

MQJM: A Comprehensive CNC Precision Machining Service

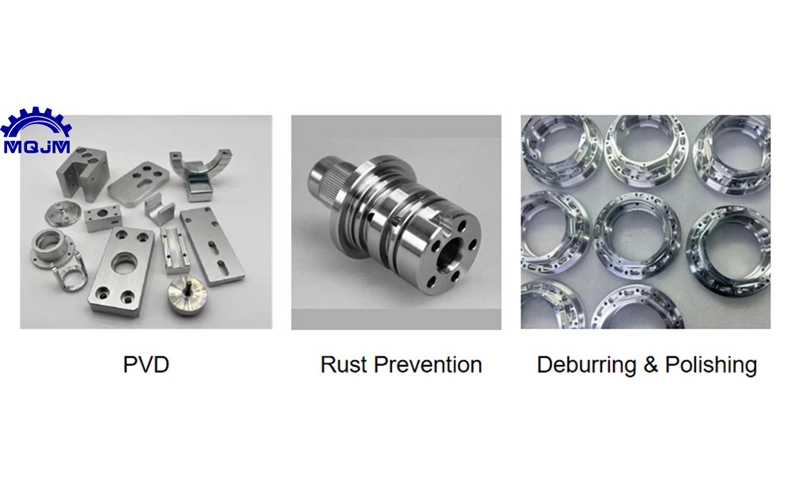

At MQJM, we offer a full-service approach, handling everything from raw material sourcing to production, QC inspection, and final packaging. Our in-house factory is equipped with advanced inspection equipment to ensure that every custom part undergoes rigorous quality checks before leaving our facility. With years of experience, we can quickly respond to unique client needs and provide professional technical support.

We understand the performance requirements of every racing and automotive part, which is why our CNC machining services prioritize not only precision but also the durability and functionality of each component. If you require custom racing, motorcycle, or automotive parts, MQJM is your trusted partner for high-quality, precision machining solutions. Feel free to contact us for more details on our custom CNC precision machining services.