CNC machine tools offer higher productivity and efficiency to hobbyists, professional businessmen, manufacturers, and various other sectors. One of the most popular and effective applications of CNC machine tools is the machining of aluminum and brass (non-ferrous metals), where increased capacity and precision allow for the completion of complex tasks in the shortest possible time without sacrificing quality.

Why Choose Brass CNC Milling

Brass is inexpensive, durable, and corrosion-resistant, capable of withstanding extreme temperatures. It is easier to cut at higher speeds and feeds without adversely affecting tool wear, surface finish, and chip formation.

Additionally, it is 100% recyclable, minimizing waste and maximizing the use of materials. Brass is commonly used in the manufacture of musical instruments and electrical components because it is a highly conductive material.

The Brass CNC Milling Process

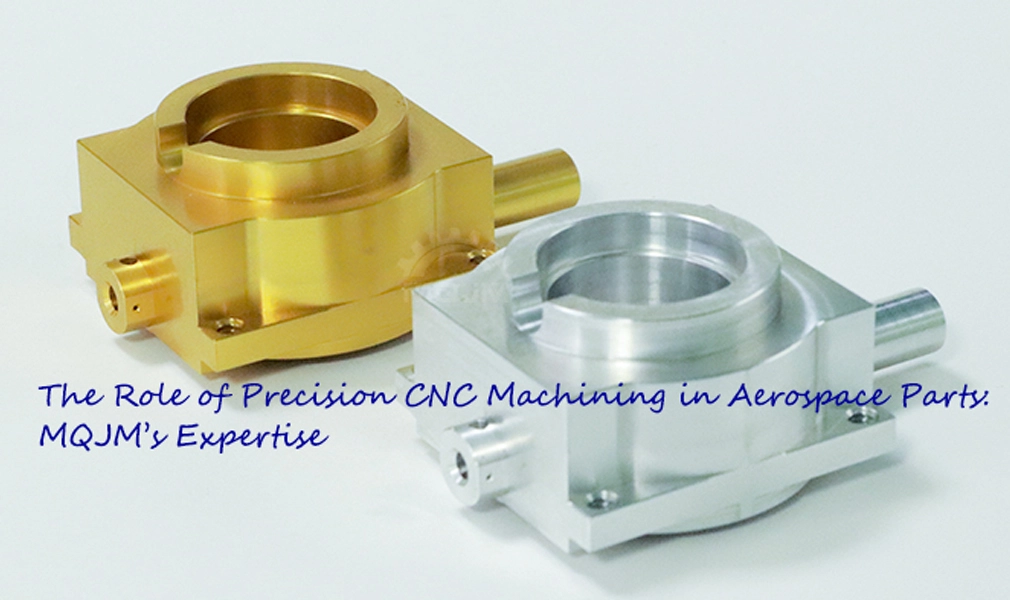

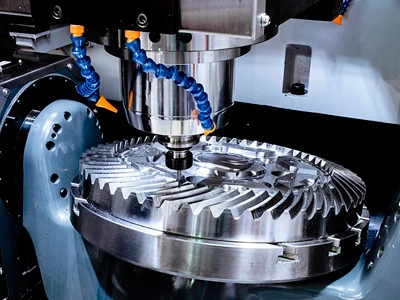

Brass is an alloy of copper and zinc, making it ideal for manufacturing CNC machined parts, including CNC milled parts. Brass CNC milling involves applying a block or sheet to the shape underneath a fixed tool spindle. This watch can rotate and pivot around two axes of movement. The cutting tool mounted on the rotating spindle removes material to form the shape.

After finishing various surface treatments such as electroplating, polishing, heat treating, nickel plating, galvanizing, tin plating, silver plating, and chromium, the final brass abrasive product can be obtained. Brass CNC milling parts are suitable for industrial equipment, smart homes, communications, and computer fields.

Characteristics of Brass CNC Milling Parts

Advantages of Brass CNC Milling

Brass has good mechanical properties, good thermoplasticity, good cold plasticity, good machinability, easy to weld and solder, and is corrosion resistant.

Brass CNC milling parts are machined using computer-controlled machine tool paths. When material shaping is required, high-speed rotating cutting tools are used. With increasing product size requirements, machining has gradually shifted from the original two-axis machining to three-axis, four-axis, and five-axis machining centers; precision can reach 3mm.

In summary, brass CNC milling technology occupies an important position in modern manufacturing. Its wide range of application fields and superior performance characteristics make it the preferred material processing method for many industrial projects. Whether it is small batch personalized customization pursued by hobbyists or large-scale efficient production pursued by professional manufacturers, brass CNC milling can provide unparalleled processing precision, efficiency, and flexibility.