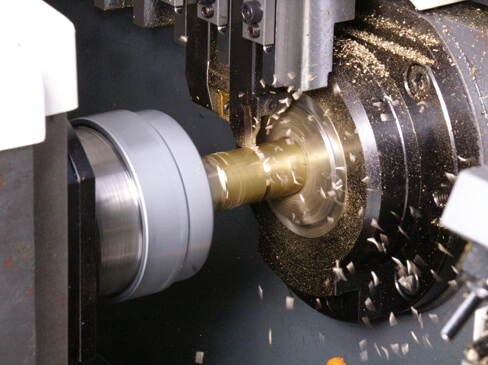

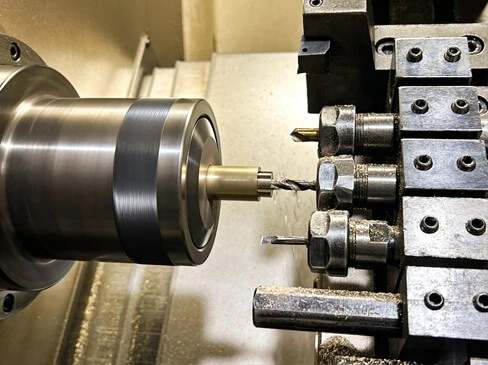

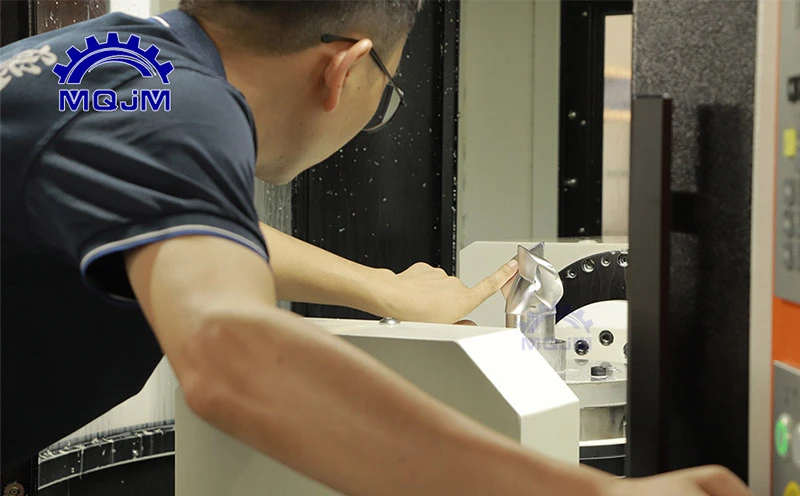

In the field of CNC custom machining, MQJM is dedicated to exceeding customer expectations. From small batch trial production to large-scale manufacturing, we solve machining challenges for global clients through advanced equipment, an efficient team, and professional CNC services. Whether improving part quality or shortening lead times, MQJM offers reliable solutions for your needs.

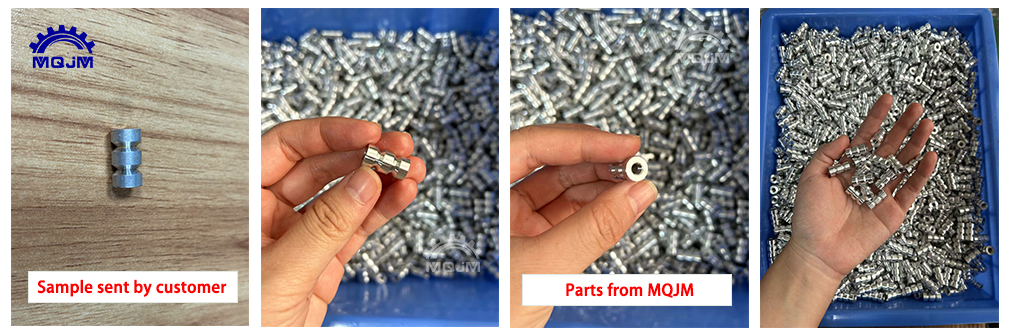

Case 1: High-Quality Aluminum Turned Parts

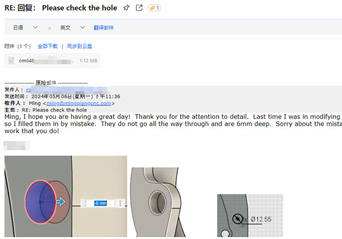

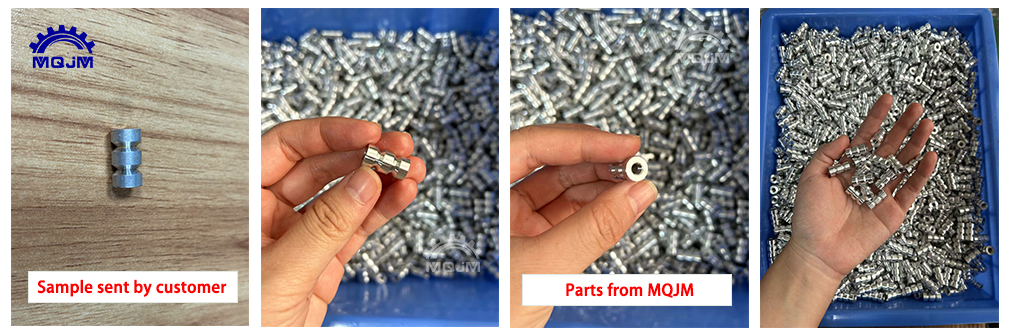

A customer from the United States sought our aluminum CNC machining service after struggling with his previous supplier. The supplier failed to meet his surface finish and inner diameter tolerance requirements and couldn't handle large-batch production, leading to long delivery times. The customer contacted us online and sent an aluminum turning part for evaluation.

Upon receiving the sample, our engineering team quickly assessed it. This was a straightforward aluminum 6061 CNC-turned part, and we confirmed we could meet the surface finish and tolerance requirements. We also promised to deliver 30,000 pieces within 20 days.

After discussing with the customer, we began a trial production of 100 pieces. The surface finish of the trial parts far exceeded the sample's quality. Our inspection team measured the hole positions, and all parts met the required tolerances. Impressed by the results, the customer ordered a batch of 30,000 pieces. After 19 days of efficient production, we delivered the order on time. The customer was delighted with the quality and efficiency and placed additional orders for OEM machined parts.

Case 2: Custom Automotive Parts

In August 2024, we received a sample from a European customer – a set of aluminum spacers for modified vehicles. The customer wanted an exact replica of the product with their company logo engraved.

Upon inspecting the sample, we found significant burrs and scratches on the surface, resulting in poor finish quality and a rough texture. We assured the customer that MQJM could replicate the part and deliver a higher-quality product.

During production, we optimized the machining process for these custom aluminum milled parts, ensuring a smooth, burr-free, and scratch-free surface. Additionally, we used laser engraving with a filled finish for the logo, making it more prominent and refined. In just 15 days, the customer received the order. They were amazed by the quick lead time and superior quality, praising our expertise in CNC machining.

Case 3: Anodized Fishing Equipment Assembly Parts

A customer from the United States left an inquiry on our website, explaining his difficulties finding a supplier that met his quality, lead time, and cost requirements. He sent us a sample of a fishing component, requesting not only CNC machining but also custom packaging and assembly services.

Our engineering team held a dedicated meeting to discuss ways to produce the fishing component faster and more cost-effectively while ensuring quality. After thorough research, we provided a comprehensive CNC service solution that covered cost control, production efficiency, and quality assurance.

Ultimately, we offered a competitive aluminum CNC machining quote, free custom packaging design, and pre-training for our assembly staff to speed up the assembly and packing process. The customer was impressed by our professionalism, service, and high-quality machining and immediately placed an order, initiating a successful partnership.

If your current supplier struggles to meet quality, lead time, or service requirements, MQJM is here to offer professional solutions. We specialize in aluminum CNC machining and can 100% replicate your samples, providing high-quality CNC turning and custom aluminum milled parts. Additionally, we offer laser marking, custom assembly, and packaging services. Choosing MQJM means choosing efficient, high-quality, and professional China CNC milling service for your OEM machined parts needs. Let’s collaborate to create greater value together!