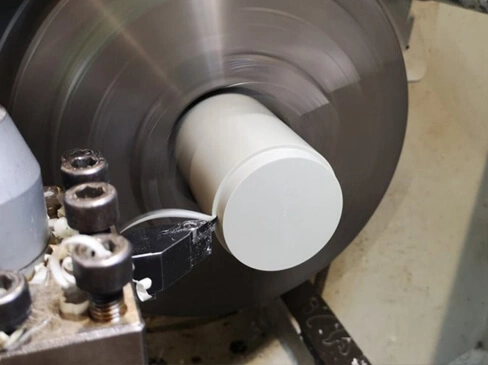

Stainless steel CNC machining is a process of high-precision and high-efficiency machining of stainless steel materials using numerical control machines (CNC), especially suitable for manufacturing precision stainless steel parts. This machining method has become the preferred method for producing stainless steel parts due to its superior precision, repeatability, and efficiency.

Why choose CNC machining for stainless steel?

High Precision

CNC machining can achieve extremely high precision by controlling the tool path via computer, satisfying the strict requirements for dimensions and shapes of stainless steel parts. It is suitable for producing various complex and highly precise parts.

Automation and Efficiency

CNC machining is fully automated, reducing human intervention and errors, thus improving production efficiency and consistency. Particularly in mass production, CNC machining can maintain the precision consistency of each part.

Machining of Complex Geometries

CNC machining technologies, including turning, milling, drilling, and grinding, can easily handle complex geometries and detailed features of stainless steel parts such as threading and fine edges. This is especially critical for high-demand industries such as precision instruments or medical devices.

Challenges of Stainless Steel CNC Machining

Material Hardness

Stainless steel's high hardness brings significant wear and heat to the tools, so choosing the appropriate tool material (such as carbide tools) is crucial.

Heat Dissipation

Stainless steel generates a lot of heat during the machining process, which can easily cause workpiece deformation or affect surface quality. Therefore, using appropriate cooling liquids or cutting fluids to control machining temperature is critical.

Machining Speed

Stainless steel's cutting speed cannot be too fast; otherwise, it can cause overheating of the workpiece and tool wear. It is necessary to control the feed rate and cutting depth properly.

Stainless Steel CNC Machining: Applications of Precision Stainless Steel Parts

Medical Equipment

Stainless steel CNC machining is used to manufacture precision medical instruments such as surgical tools, implants, and dental instruments, which require extremely high dimensional accuracy and surface finish.

Automotive Parts

The application of stainless steel in automotive manufacturing is becoming increasingly widespread, such as engine parts, exhaust systems, and precision components within steering systems.

Aerospace

In the aerospace field, stainless steel materials are used to manufacture precision parts like aircraft engine components due to their high-temperature resistance and high strength characteristics.

Electronic Equipment

Precision stainless steel parts are used in high-end electronic devices, such as metal casings in smartphones, micro connectors, and heat sinks.

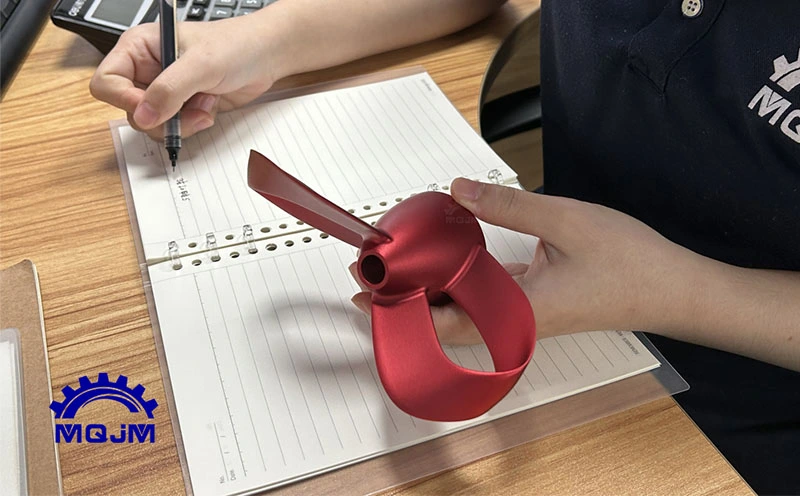

Stainless steel CNC machining is the preferred method for producing precision stainless steel parts due to its high precision, high efficiency, and adaptability to complex geometries. The strength and corrosion resistance of stainless steel make it widely used in fields ranging from medical equipment and automotive parts to aerospace. By selecting the right tools, cooling techniques, and precise CNC machining processes, it can ensure that the machined stainless steel parts meet high standards.

MQJM has been offering stainless steel CNC machining services for 13 years, rich in experience and technology, dedicated to providing high-quality and cost-effective products to customers. You are welcome to consult and learn more!