With the rapid development of modern industry, aluminum alloy, as a lightweight and high-strength material, has been widely used in various fields. As CNC machining technology continues to advance, the machining of aluminum alloy parts becomes more precise and efficient. However, ensuring the quality and efficiency of CNC machining of aluminum alloy parts requires attention to a series of key techniques and considerations. Here, we will elaborate on various factors that need to be considered, drawing on the experience of MQJM, a professional factory specializing in CNC machining of aluminum alloy parts.

I. Characteristics of Aluminum Alloy Materials

Aluminum alloy, as a common metal material, possesses several main characteristics:

1. Low density and high strength: Aluminum alloy has a low density and high specific strength, making it widely used in fields such as aerospace and automotive manufacturing.

2. Good thermal and electrical conductivity: Aluminum alloy exhibits good thermal and electrical conductivity, making it an ideal material for manufacturing heat sinks and electrical components.

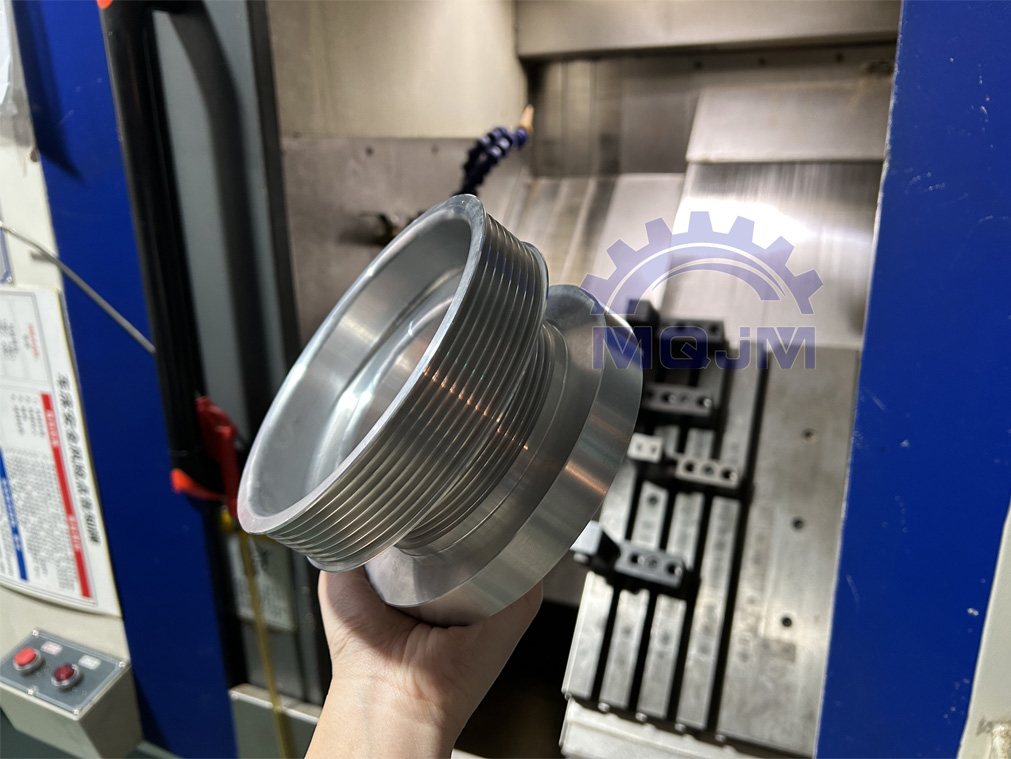

3. Ease of machining: Aluminum alloy has good machinability and can be formed using various machining processes such as milling, turning, and punching.

4. Susceptibility to oxidation: Aluminum alloy is prone to oxidation in the air, forming an oxide film that affects its surface quality and corrosion resistance.

Considering these characteristics, CNC machining of aluminum alloy parts requires corresponding adjustments and treatments to ensure machining quality and efficiency.

II. Technological Techniques and Equipment Selection

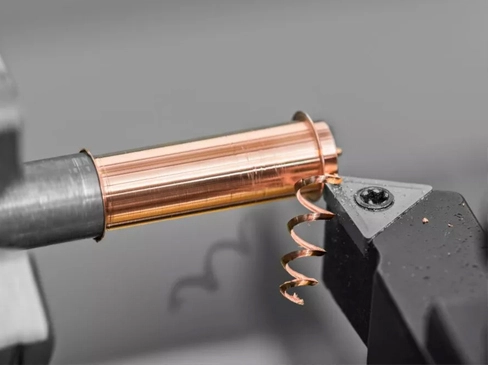

1. Tool selection and cutting parameter adjustment: When machining aluminum alloy parts, it is necessary to choose suitable cutting tools and adjust cutting parameters according to specific machining requirements. For example, selecting appropriate tool types (such as carbide tools), and controlling cutting speed and feed rate.

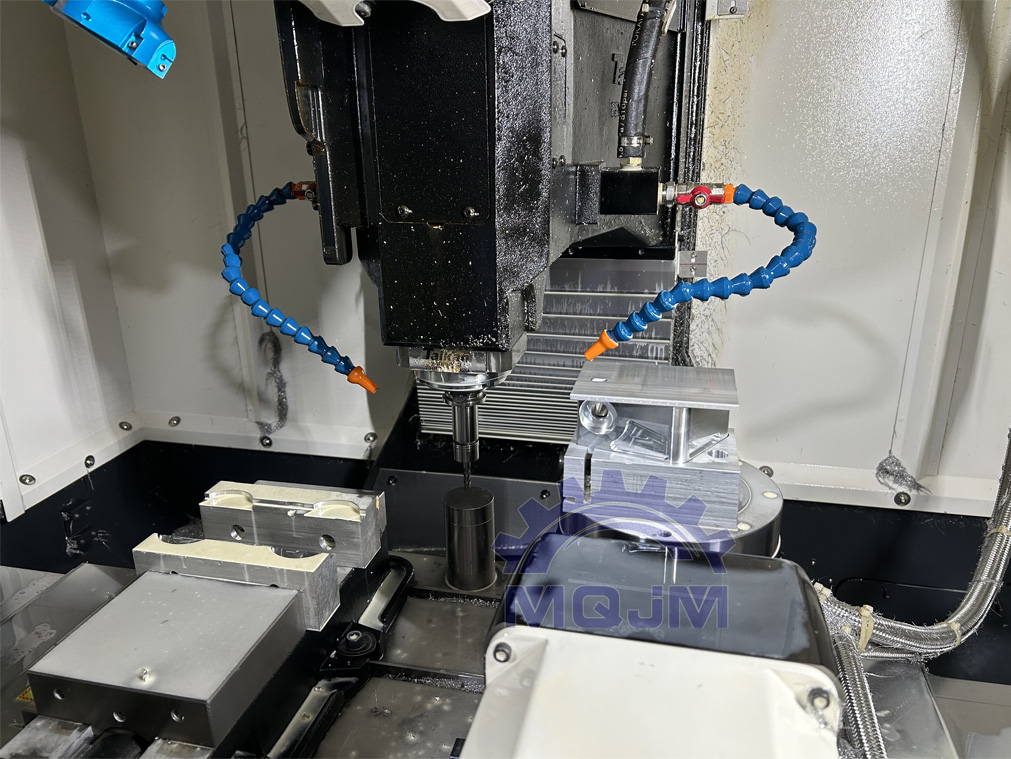

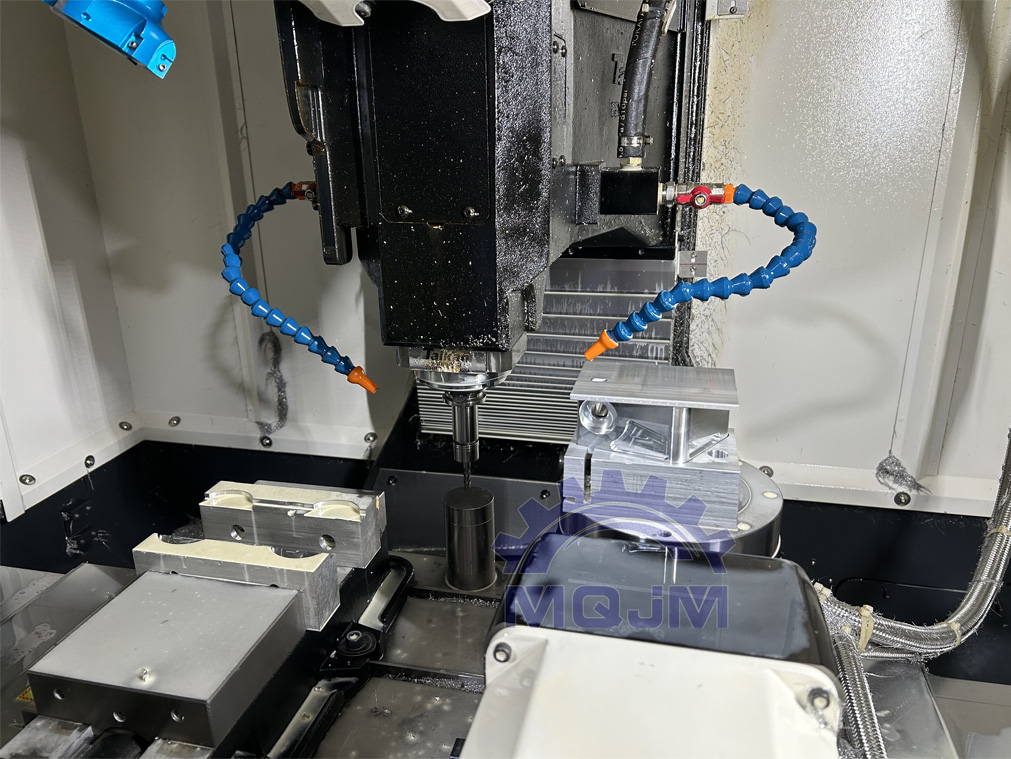

2. Fixture design and machining route planning: Fixture design and machining route planning are critical factors affecting machining efficiency and precision. It is essential to design rational fixtures and plan efficient machining routes to reduce machining time and improve production efficiency.

3. Equipment selection and maintenance: CNC machine tools are crucial equipment for machining aluminum alloy parts. It is necessary to select CNC machine tools with high precision, rigidity, and stability, and strengthen equipment maintenance to ensure normal operation.

4. Cooling and lubrication technology: Proper cooling and lubrication technology can effectively reduce cutting temperature, decrease cutting force and friction, prevent surface oxidation, and extend tool life. Methods such as using cutting fluids or air cooling can be employed for cooling and lubrication treatment.

III. Quality Control and Safety Environmental Protection

1. Quality control system: Establish a comprehensive quality control system, including quality inspection procedures before, during, and after machining, to ensure that the dimensions and surface quality of parts meet requirements.

2. Safety production and environmental protection measures: Strengthen employee safety awareness training, strictly implement safety operating procedures, and take necessary safety protection measures. At the same time, enhance environmental protection awareness, implement energy conservation and emission reduction measures, and reduce environmental pollution.

IV. Talent Cultivation and Team Building

1. Technical training and experience inheritance: Provide systematic technical training and job training for machining personnel to improve their machining skills and capabilities. Strengthen communication and exchange with senior technical personnel to inherit experience.

2. Team building and incentive mechanisms: Build teamwork awareness, enhance team cohesion and execution. Establish reasonable incentive mechanisms to inspire employees' enthusiasm and creativity.

V. Common Problems and Solutions in CNC Machining of Aluminum Alloy

1. Machining deformation problem: Due to the large plasticity of aluminum alloy, machining may easily cause cutting deformation, affecting machining accuracy. Solutions include optimizing tool geometry, controlling cutting parameters, and increasing rigid clamping to reduce cutting deformation.

2. Surface quality problem: Aluminum alloy surfaces are prone to oxidation and scratches, affecting the appearance and performance of products. Solutions include selecting appropriate cutting fluids for cooling and lubrication, adjusting cutting speed and feed rate, and improving tool edge quality to improve machining surface quality.

3. Tool wear problem: Aluminum alloy's good plasticity and thermal conductivity make it susceptible to tool wear. Solutions include selecting tool materials with good wear resistance, optimizing tool geometry, and controlling cutting parameters to extend tool life.

4. Low machining efficiency problem: Aluminum alloy's characteristics and machining requirements may lead to low machining efficiency. Solutions include optimizing machining process flow, improving equipment operating stability, and arranging production plans reasonably to enhance machining efficiency and production capacity.

VI. Case Analysis and Experience Summary

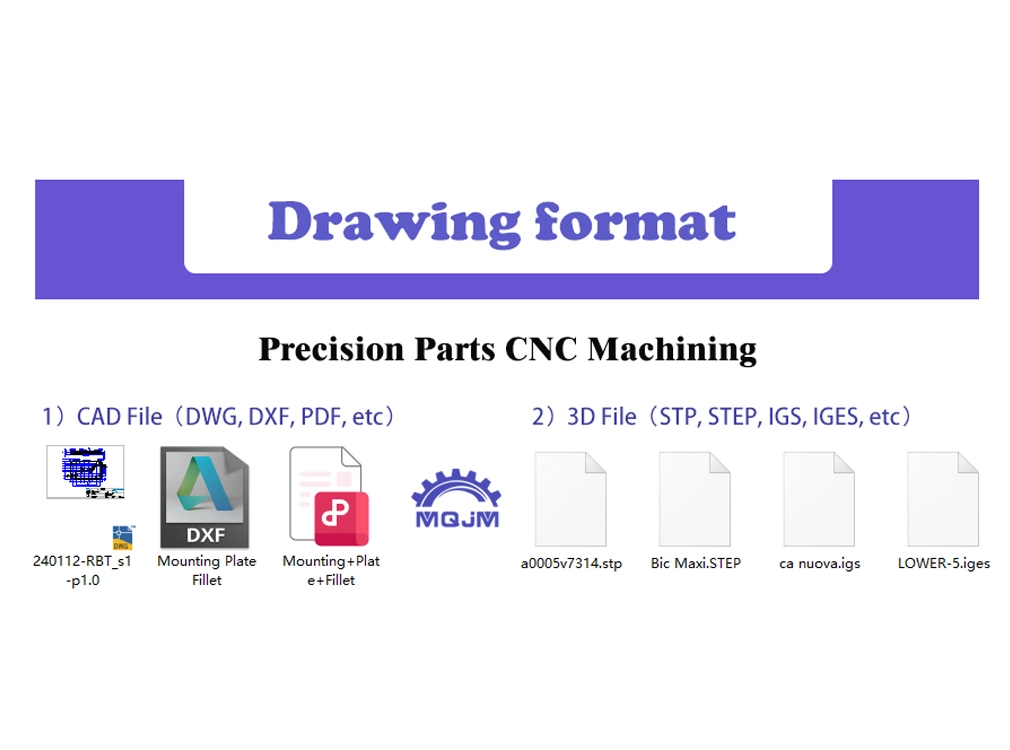

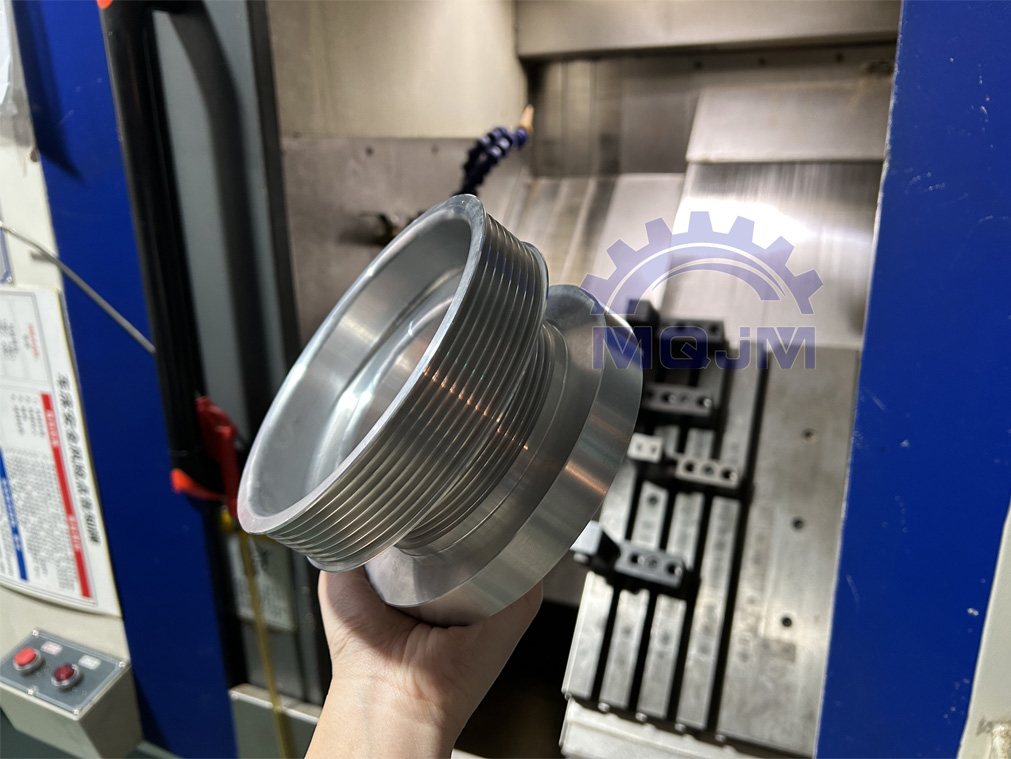

Taking a customer order as an example, the customer required customization of a batch of aluminum alloy parts with high dimensional accuracy and good surface finish. In response to this demand, MQJM, a professional manufacturer of aluminum alloy CNC machining, took the following measures:

1. Optimizing process flow: Designed a reasonable machining process flow based on the shape and machining requirements of the parts, including selecting cutting parameters, optimizing tools, and designing fixtures, to ensure machining quality and efficiency.

2. Precision machining control: Strengthened monitoring and control of the machining process, strictly controlling cutting parameters and machining environment to ensure that each step meets the requirements of precision machining and ensures dimensional accuracy and surface quality of parts.

3. Quality inspection and feedback: Conducted multiple quality inspections and evaluations during the machining process, promptly identifying problems and taking measures to solve them to ensure that the quality of parts meets customer requirements.

Through the above measures and methods, the customer's order was successfully completed, and received unanimous praise from the customer. This experience not only improves the professional level of MQJM in the field of aluminum alloy machining but also provides valuable experience and reference for future production and operation.

VII. Conclusion

CNC machining of aluminum alloy, as a high-precision and efficient machining technology, plays an increasingly important role in modern industrial production. However, to ensure machining quality and efficiency, machining manufacturers need to have an in-depth understanding of the characteristics and machining requirements of aluminum alloy materials, reasonably select process technology and equipment, and continuously summarize experience to improve technical level. Only in this way can we better meet market demand, promote the development and progress of the industry. Let us work together to make greater contributions to the development of the aluminum alloy CNC machining industry!