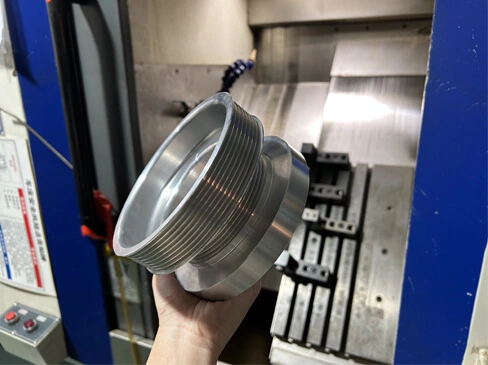

It is very important to control the machined surface quality in aluminum CNC machining. Here are some common control methods and techniques:

Tool selection and maintenance:

Tool material: Select the tool material suitable for aluminum machining (e.g., carbide, high-speed steel, etc.).

Tool Geometry: Use proper tool geometry, such as larger rake and rake angles, to reduce cutting forces and cutting temperatures.

Tool Sharpness: Keep the tool sharp and regularly inspect and replace worn tools.

Cutting parameters:

Cutting speed: Appropriate increase in cutting speed can reduce surface roughness, but need to be careful not to be too high to avoid rapid tool wear.

Feed speed: feed speed is too high will lead to increased surface roughness, should be based on the specific circumstances of the selection of the appropriate feed speed.

Depth of cut: the depth of cut should not be too large to avoid deformation of the tool and workpiece.

Cooling and lubrication:

The use of appropriate cutting fluid or lubricant can effectively reduce the cutting temperature, reduce thermal deformation and tool wear, thus improving surface quality.

Keep the cutting fluid clean and at the proper flow rate to ensure adequate cooling and lubrication.

Clamping and support:

Choose appropriate clamps to ensure that the workpiece is stable and motionless during machining, reducing vibration and deformation.

For longer or thinner workpieces, auxiliary supports can be used to minimize distortion.

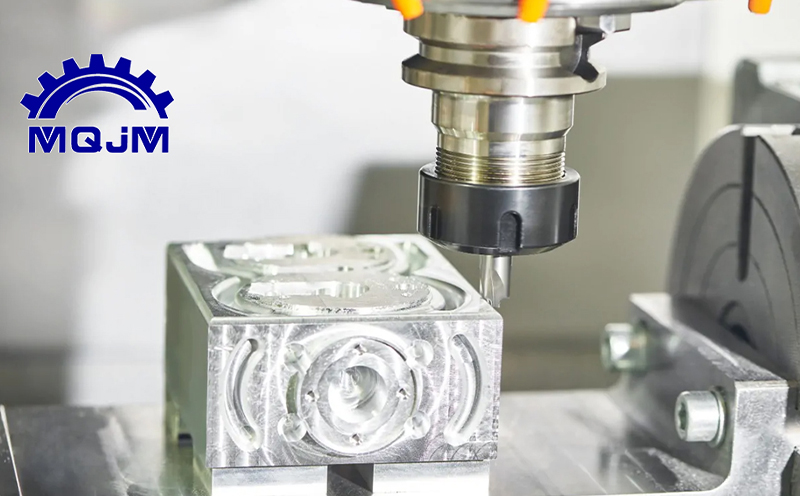

Machine Tools and Programming:

Machine tool accuracy: Choose high-precision CNC machine tools, and regularly maintain and calibrate them to ensure their accuracy.

Machining path: Reasonable planning of the machining path, avoid unnecessary tool change and feed/release to minimize surface scratches and roughness.

Machining environment:

Keep the temperature and humidity of the machining environment stable to avoid thermal deformation of the workpiece and machine tool due to environmental changes.

Through the above methods, the surface quality of aluminum CNC machining can be effectively controlled to improve the precision and appearance quality of the product. If you have specific machining cases or problems, welcome to describe them in detail, MQJM can provide more targeted advice.