What is CNC Milling?

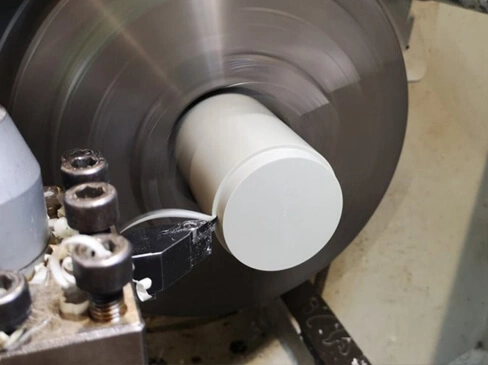

CNC milling is a subtractive manufacturing process where computer-controlled cutting tools gradually remove material from a workpiece to create the desired shape or object. This process is achieved using a CNC milling machine or CNC mill. CNC milling is a widely used machining process, alongside other machining processes like CNC turning and CNC drilling.

Aluminum is one of the most commonly used materials in current machining processes. In fact, custom CNC machining services of aluminum is second only to steel in terms of usage. The chemical element aluminum, in its high-purity form, is soft, ductile, non-magnetic, and has a silver-white appearance. However, the element is not only used in its pure aluminum state. Aluminum is often alloyed with various elements, such as manganese, copper, and magnesium, to form various aluminum alloys that possess significantly improved properties.

What is Aluminum CNC Milling?

Aluminum CNC milling is the most commonly used process when machining aluminum parts. These processes involve multi-point cutting along the axis while the workpiece remains stationary along the axis. Cutting actions and subsequent material removal are achieved by feed motions, which can be either from the workpiece, the cutting tool, or a combination of both. This motion can occur along multiple axes.

What are the principles of Aluminum CNC Milling?

Aluminum CNC milling utilizes milling principles. Commonly used tool diameters for aluminum CNC milling are typically between 6-40 millimeters. One modern successful method of aluminum CNC milling is known as high-speed machining. The primary difference compared to traditional milling is that high-speed milling occurs at much higher speeds, allowing operators to increase feed rates during cutting.

Advantages of Aluminum CNC Milling Services

High Precision

Aluminum CNC milling provides precise control over the position coordinates of the aluminum alloy workpiece, tool feed speed, spindle speed, etc., via numerical control machining language. This enables precise milling and machining of aluminum profiles, with accuracy reaching micron levels.

High Efficiency

Aluminum CNC milling achieves automated production through computer program-controlled machining equipment, significantly improving production efficiency. Compared to traditional manual and conventional machining, aluminum CNCmilling can complete milling, drilling, tapping, and other processes more quickly and accurately, reducing production cycles.

Machining Complex Shapes

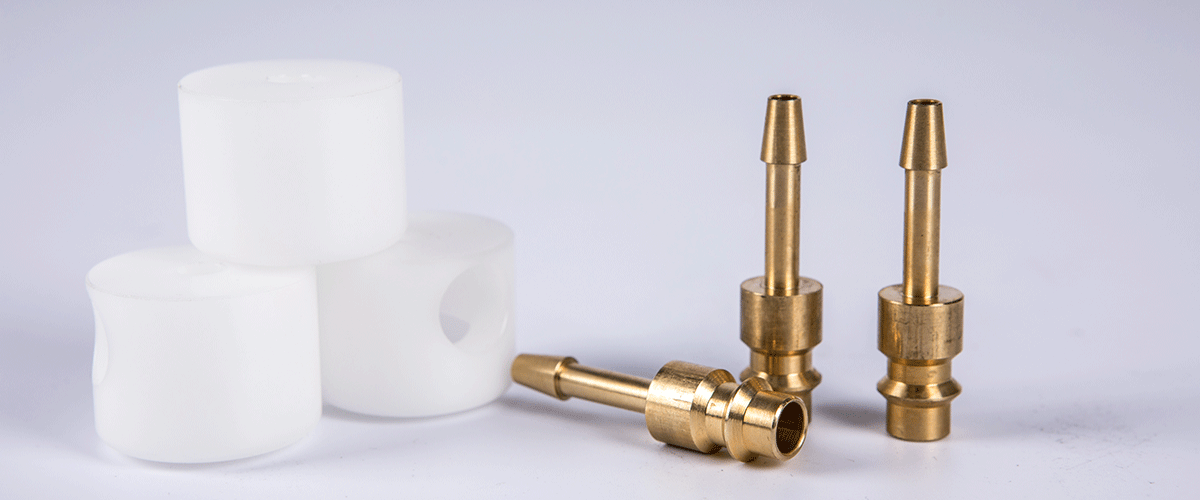

Aluminum CNC milling has powerful machining capabilities, enabling the machining of various complex shapes of aluminum profile workpieces. Whether it's curves, hollowed-out designs, or irregular workpieces, aluminum CNC milling can handle them easily, meeting diverse design requirements.

Stability

Aluminum alloys and their alloys possess high strength, which can be further enhanced through cold working or heat treatment. Therefore, the aluminum CNC milling process is stable, avoiding manual machining deviations and ensuring the consistency of each aluminum alloy workpiece.

In summary, aluminum CNC milling services offer high precision, high efficiency, the ability to machine complex shapes, and stability in the manufacturing industry. These advantages have led to the extensive application of aluminum CNC milling services, providing significant economic and social benefits to enterprises.

Why Choose MQJM's Aluminum CNC Milling Services?

As one of leading custom CNC precision machining suppliers, MQJM is dedicated to providing high-quality aluminum CNC milling service to customers. With 13 years of experience, MQJM has consistently focused on aluminum CNC milling services, continuously improving technology to ensure the highest quality of aluminum CNC milling services. MQJM's outstanding expertise allows it to machine all types of aluminum CNC milling parts for clients. Whether you need simple or complex components, MQJM has the capability to deliver. Custom machining of aluminum parts is also a part of MQJM's custom aluminum CNC milling services, meeting various order sizes and providing high-quality aluminum milling products from small to large batch production.