In modern manufacturing, CNC Curved Surface Machining have become an important mode of production. With its high precision, high efficiency, and high flexibility, it provides infinite possibilities for all industries. Below, as a professional CNC precision machining manufacturer, we will delve into the charm of CNC Curved Surface Machining.

I. Precision Manufacturing of CNC Curved Surface Machining

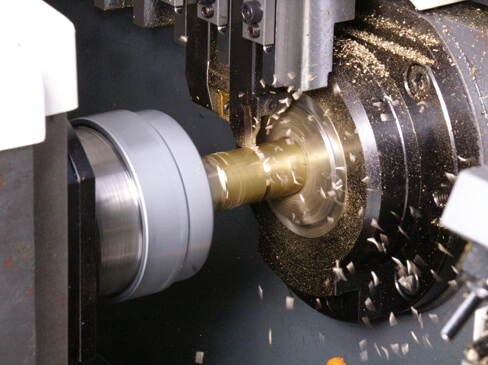

CNC Curved Surface Machining are precisely processed on complex three-dimensional surfaces through computer numerical control technology. This processing method can achieve high-precision, high-quality parts manufacturing, meeting the needs of various high-end equipment. Whether it's aerospace, automotive manufacturing, medical equipment, or precision instruments, they all rely on the support of CNC Curved Surface Machining.

The precision of CNC Curved Surface Machining can reach the micron level, which is incomparable to traditional manual processing. Moreover, the repeatability and consistency of CNC Curved Surface Machining are also very high, greatly improving production efficiency and product quality.

II. High-Efficiency Production of CNC Curved Surface Machining

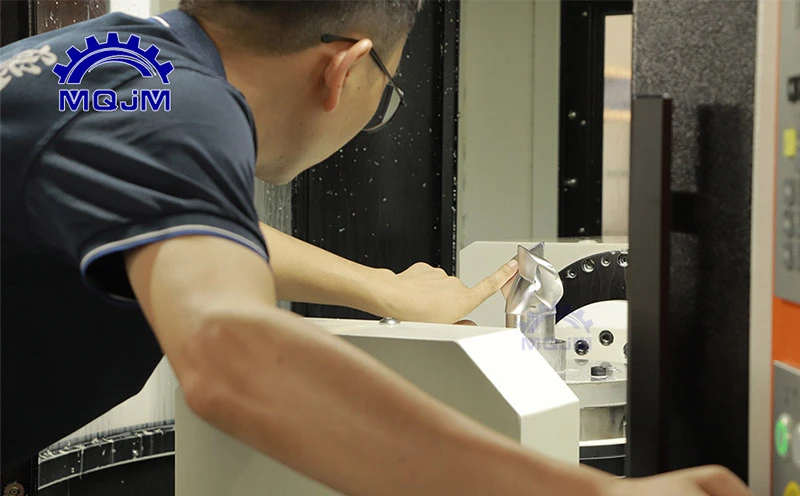

Another advantage of CNC Curved Surface Machining is high efficiency. Through computer programming, automated production can be achieved, greatly reducing the time and errors of manual operations, realize rapid CNC machining. At the same time, the processing speed of CNC Curved Surface Machining is also very fast, which can meet the needs of mass production.

In addition, the flexibility of CNC Curved Surface Machining is also very high. By simply changing the program, different shapes and sizes of parts can be processed without changing tools and equipment, greatly saving production costs.

III. Wide Application of CNC Curved Surface Machining

The application of CNC Curved Surface Machining is very wide. In the aerospace field, CNC Curved Surface Machining can be used to manufacture complex engine parts and spacecraft parts. In the automotive manufacturing field, CNC Curved Surface Machining can be used to manufacture high-precision engine parts and body parts. In the field of medical equipment, CNC Curved Surface Machining can be used to manufacture precision medical instruments and human implants.

Conclusion

CNC Curved Surface Machining, with their high precision, high efficiency, and high flexibility, are changing the way humans produce and live. It is the future of precision manufacturing and an important tool for humans to move towards a high-quality life. Let's look forward to more innovations and breakthroughs brought by CNC Curved Surface Machining.