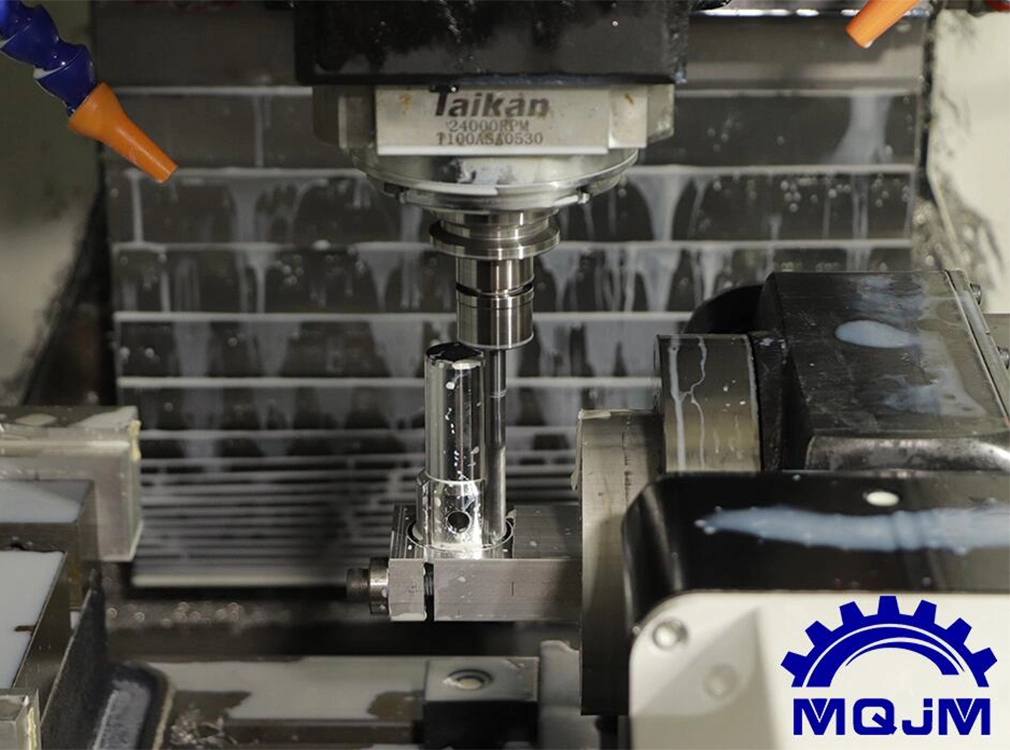

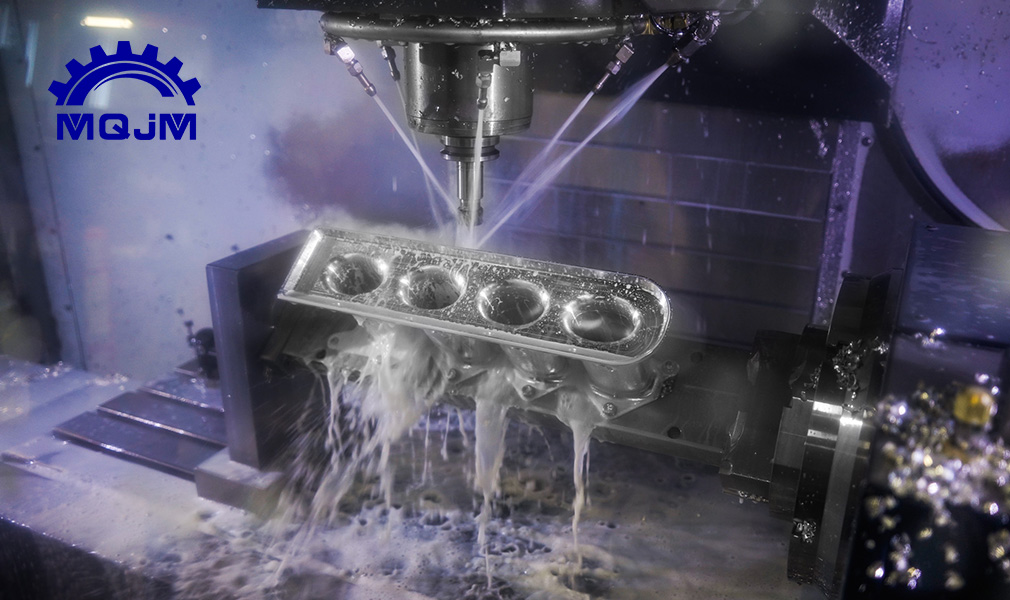

In Guangming District, Shenzhen, China, there is a CNC machining factory named MQJM. Since its founding in 2010, MQJM has grown under the leadership of its founder and senior engineer, Mr. Gu, from an initial setup of five machines to over 60 advanced pieces of equipment, becoming a shining star in the industry.

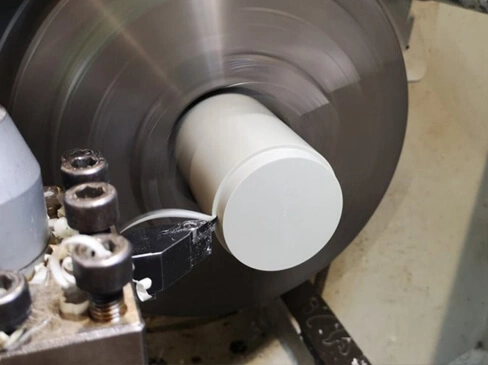

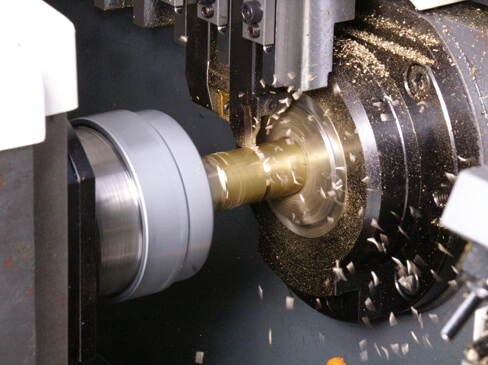

The Motivation Behind CNC Machining

Mr. Gu's passion for custom CNC machining services began when he first encountered the industry. He was deeply fascinated by the process of transforming raw materials into finished products and was immersed in the anticipation of seeing each part completed. This enthusiasm drove him to firmly establish himself in the CNC machining industry and create MQJM in 2010.

Extensive Industry Experience

Before founding MQJM, Mr. Gu worked as an engineer for many years at another CNC machining factory, where he accumulated a wealth of experience. This period allowed him to handle various CNC products with different requirements and materials, understanding the industry's production standards and laying a solid foundation for the creation of MQJM.

From 6 Employees to Over 30

MQJM has grown from its initial six employees to a team of over 30. This achievement is largely due to Mr. Gu's excellent management skills. He understands the nature and challenges of each position, which enables him to implement different incentive measures.

Flexible Reward System

Having worked in every position for 3-5 months, Mr. Gu provides different subsidies and bonuses tailored to each role. For instance, during the hot summer months, he offers cooling equipment, cold drinks, and high-temperature allowances to custom CNC milling machine operators to reduce their fatigue.

Team Building Activities

To enhance team cohesion, Mr. Gu plans production in advance and organizes trips to various cities, along with group activities during the trips. He also regularly hosts team dinners, allowing employees to bond in a relaxed atmosphere, fostering harmony in the workplace.

A Masterful Engineer

Mr. Gu is not only an excellent manager but also a highly skilled engineer who provides the most reasonable and cost-effective solutions for customers. His expertise has earned MQJM many long-term clients.

Expertise in CNC Programming and Machining

Mr. Gu's enthusiasm for challenging products led MQJM to equip itself with 10 five-axis CNC machines to meet diverse customer needs. Last month, he personally handled a complex yacht engine part made of aluminum, which required precision within ±0.0005mm. After days of research and processing, he successfully completed the part, and the client was extremely satisfied with the result.

Effective Cost Management

In his quotations, Mr. Gu always considers the customer's perspective to propose the best product solutions. For example, last week, he received an inquiry from a Japanese client about manufacturing chopsticks. He noticed that the squared design at the tip increased machining difficulty and cost. He suggested adding rounded corners, which reduced production costs. The client accepted his suggestion, achieving more economical production.

Mr. Gu consistently emphasizes that MQJM should not harm customers' interests for its own benefit. This sincerity and kindness enable MQJM to meet customers' needs comprehensively in solutions, CNC product machining, and part packaging.

Mr. Gu's professional spirit and care for his team have distinguished MQJM in the CNC machining industry. He is not only an outstanding engineer but also an exceptional leader. His story inspires everyone who loves technology and pursues their dreams.