The introduction of automobiles changed entire civilizations, providing fast personal transportation for the majority of the population. Today, the automobile industry spans the globe.

Since the development of the first automobile, manufacturing processes have undergone significant changes. During the mass production of the Ford Model T, a large labor force was united to manually assemble parts. Post-1960, robots briefly became the mainstream for performing part assembly and welding. Apart from assembly and welding, the production of automotive parts also requires other operations such as milling, drilling, boring, and turning.

In today's automotive market, competition is becoming increasingly fierce. To stand out, manufacturers must quickly redesign vehicle models, which requires the production of extremely complex and specialized shapes. As a result, CNC has become one of the essential processes for producing automotive parts (CNC machined car parts).

The Importance of CNC Automotive Parts Processing

Maintaining the integrity of materials and achieving the strict tolerances required by manufacturers for automotive parts is a daunting task. Therefore, CNC machined products have come to dominate the automotive industry.

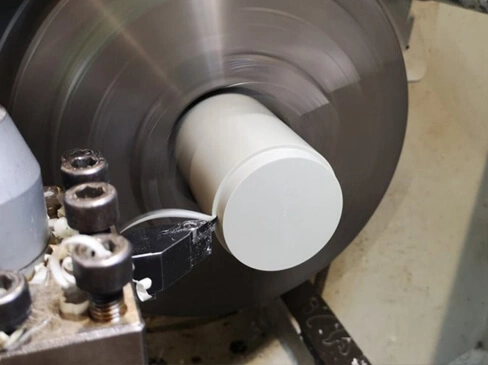

Automated CNC machine tools take G and M codes as inputs and convert them into a series of operations. Electric tools like drills, lathes, or milling machines then perform the corresponding operations. Compared to traditional parts machining, CNC machined car parts offer higher accuracy and better meets the standards required by automotive manufacturers.

By mass-producing similar parts to meet market demands, CNC machine tools have transformed the entire automotive industry.

Applications of CNC in the Automotive Industry

The engine is the most complex and primary component of any system that keeps the vehicle running.

Because of its complexity and the variety of materials used, CNC machining is an excellent method for creating this component.

Programming CNC machine tools is a daunting and time-consuming task that requires a high level of skill. Once set up, the machine can produce many engine blocks with the same precision and tolerance without any help or additional labor.

Many parts related to the engine block, such as cylinder heads, intake manifolds, and parts surrounding the cylinders and the block, are commonly produced using CNC machine tools.

Adapters made of aluminum and steel in various thread configurations require high precision and strict tolerances. Thus, CNC turning and CNC milling have become one of the best options for mass-producing these adapters. Reflectors made of PMMA and acrylic glass also require high precision and strict tolerances, making CNC machining the optimal choice for mass production.

The starter motor, which makes the internal combustion engine work on its own, has a complex design and requires a manufacturing process with very high accuracy, precision, and strict tolerances.

CNC machining is the ideal solution to meet these constraints and helps manufacturers produce parts that meet the required precision, accuracy, and tolerances.

CNC machining can also properly optimize essential car components as per design requirements.

The two half-shafts of the drive bridge are connected to the wheels via constant velocity joints. This critical component ensures the smooth operation of the wheels, thus requiring high precision and accuracy.

CNC machining is beneficial for producing parts like the quasi-hypoid gears and bevel gears of the drive bridge mechanism.

The design of a gearbox is complex and requires very strict tolerances to fit into small spaces.

Any slight error in tolerance during manufacturing can lead to misalignment, gear wear, and gear failure.

Many automotive manufacturing companies are minimizing the use of traditional gear manufacturing processes, such as gear hobbing, in favor of CNC machining.

CNC machining can produce high-quality gears with high precision, accuracy, and strict tolerances without additional post-processing operations.

Body panels are light in weight but twice as thick as steel.

CNC machining is used to produce these panels with high precision and surface finish.

Dashboard frames, speedometers, and fuel gauges are primarily produced using polypropylene (PP) blocks via CNC machine tools.

This ensures that the cuts in these parts are perfectly aligned, eliminating the need for any other connecting mechanisms.

Car Wheels and Other Accessories

Using CNC machining, several other parts of a car can be produced, such as suspension components, exhaust parts, carburetor housings, fluid system parts, bushings, retainers, rotors, and brakes.

CNC machining also helps in producing custom parts for specific vehicles by altering part designs through CAD.

Advantages of CNC Machining in the Automotive Industry

CNC machining operations can be performed quickly with minimal labor intervention as it relies on computer instructions.

This machining process has significantly increased productivity for manufacturers, especially since computer instructions can be repeated multiple times.

In CNC machining, automation is an advantage, shortening production time compared to traditional processes.

Automation simplifies part manufacturing. Once a part is complete, robotic arms assist in removing it from the machine.

Over longer periods, CNC machines can quickly repeat their functions without any discrepancies.

This computer-controlled machine can produce parts multiple times without losing consistency between parts. Automotive manufacturers heavily rely on this machining process for batch production of individual parts.

With minimal labor intervention, mass production using CNC is more cost-effective. This is one of the best advantages of CNC machines in the automotive industry.

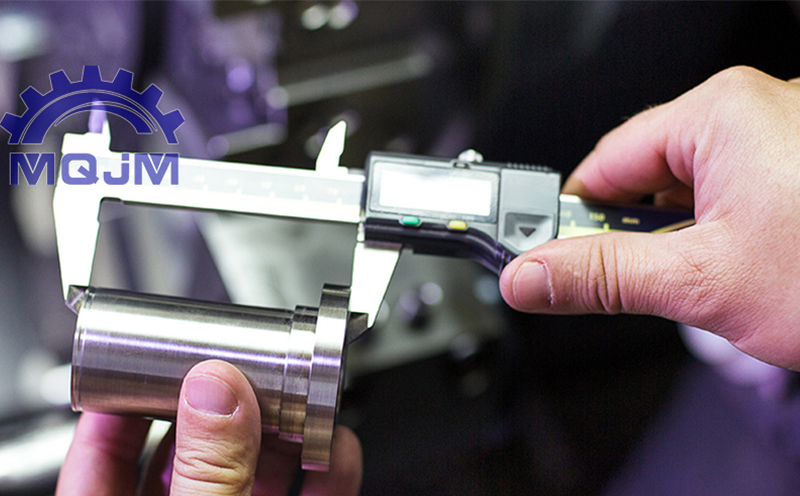

The computer control and automation features of CNC machining do not allow for any errors and can provide tolerances of ±0.001.

The automotive industry requires these fine tolerances, as failure of any critical vehicle component can have severe consequences for the end-user.

CNC machines can produce complex automotive parts with high precision, high accuracy, and strict tolerances.

MQJM is a CNC machining factory with 14 years of experience, specializing in providing machining services for CNC automotive parts and other components. We look forward to cooperating with you!