In CNC milling from MQJM, handling complex shapes and surfaces is a challenging task that requires comprehensive consideration of various factors, including tool selection, programming methods, machine accuracy, and process parameters. Here is a detailed explanation:

1. Tool Selection

a. Ball End Mills

Ball end mills are ideal for machining complex surfaces as their rounded ends can smoothly move along the contours, reducing surface roughness caused by changes in tool contact angles. Their main advantages include:

- Reduced Tool Marks: Ball end mills evenly distribute cutting forces, reducing tool marks on the machined surface.

- Multi-Directional Machining: Suitable for multi-axis machining, allowing contact with the workpiece surface from different directions.

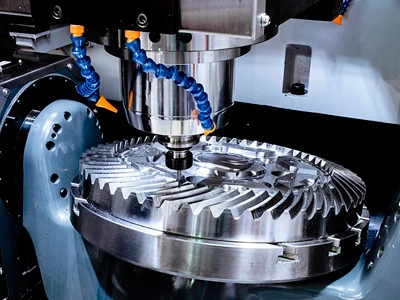

b. Milling Tools

Milling tools include end mills, face mills, and side mills, mainly used for roughing and semi-finishing to quickly remove large amounts of material, preparing for subsequent finishing. Their advantages include:

- High Material Removal Rate: Suitable for roughing operations, quickly removing excess material.

- Variety of Shapes and Sizes: Different types of milling tools can be selected based on the workpiece shape, improving machining efficiency.

2. Programming Methods

a. CAD/CAM Software

Using advanced CAD/CAM software (such as Mastercam, UG NX, and PowerMill) is key to handling complex shapes and surfaces. These software have the following features:

- Automatic Tool Path Generation: The software can automatically generate optimal tool paths, reducing the complexity of manual programming.

- Multi-Axis Support: Supports 3-axis, 4-axis, and 5-axis simultaneous machining, better handling complex geometries.

- Simulation Function: Allows for simulation before machining to verify tool paths and machining processes, reducing errors during actual machining.

b. Multi-Axis Machining

Multi-axis machining (such as 4-axis and 5-axis) offers significant advantages:

- Reduced Fixture Changes: Multi-axis machining can machine the workpiece from multiple directions in a single fixture setup, reducing the number of fixture changes and ensuring machining accuracy.

- Complex Geometry Machining: Capable of handling more complex geometries and surfaces with a wider range of machining capabilities.

c. Zoning Machining

Zoning machining divides complex surfaces into multiple controllable areas and machines each area individually:

- Precise Control: Each area’s machining parameters and tool paths can be controlled independently, improving machining quality.

- Increased Efficiency: Helps optimize tool paths and machining sequences, enhancing overall machining efficiency.

3. Machine Accuracy

a. Machine Selection

Choosing high-precision CNC machines is crucial as they typically have better rigidity and stability:

- High-Precision Linear Guides: Reduce friction and improve positioning and repeatability accuracy.

- High Rigidity Structure: Reduce vibration and deformation during machining, maintaining high-precision machining.

b. Calibration and Maintenance

Regular calibration and maintenance of the machine are key to ensuring accuracy:

- Axis Calibration: Regularly calibrate the straightness and perpendicularity of each axis to ensure movement accuracy.

- Tool Holder Inspection: Check and replace tool holders to ensure secure tool fixation and reduce errors.

- Lubrication Maintenance: Lubricate machine guides and screws to reduce wear and maintain smooth movement.

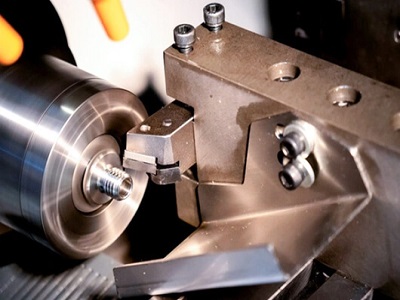

4. Process Parameters

a. Feed Rate and Spindle Speed

Select appropriate feed rate and spindle speed based on the material and tool:

- Finishing: Use lower feed rates and higher spindle speeds to reduce surface roughness and improve surface quality.

- Roughing: Use higher feed rates and lower spindle speeds to quickly remove material and improve efficiency.

b. Cutting Depth and Step Over

The selection of cutting depth and step over requires comprehensive consideration of machining efficiency and surface quality:

- Roughing: Larger cutting depth and step over can be chosen to increase material removal rate.

- Finishing: Smaller cutting depth and step over reduce cutting forces and improve surface smoothness.

c. Coolant and Lubrication

Coolants and lubricants play a critical role in the machining process:

- Cooling: Reduces cutting temperature, minimizing thermal deformation and tool wear.

- Lubrication: Reduces cutting friction, extending tool life and improving machining quality.

5. Surface Quality Control

a. Tool Path Optimization

Optimizing tool paths can improve surface quality:

- Reduced Contact Time: Avoid repeating machining in the same area, reducing tool-workpiece contact time.

- Uniform Cutting: Select appropriate cutting direction and path to ensure uniform cutting, reducing surface waves and tool marks.

b. Post-Processing

Post-processing can further improve surface quality:

- Polishing: Use polishing tools or equipment to remove fine tool marks and enhance surface finish.

- Grinding: Use fine grinding to improve surface flatness and gloss.

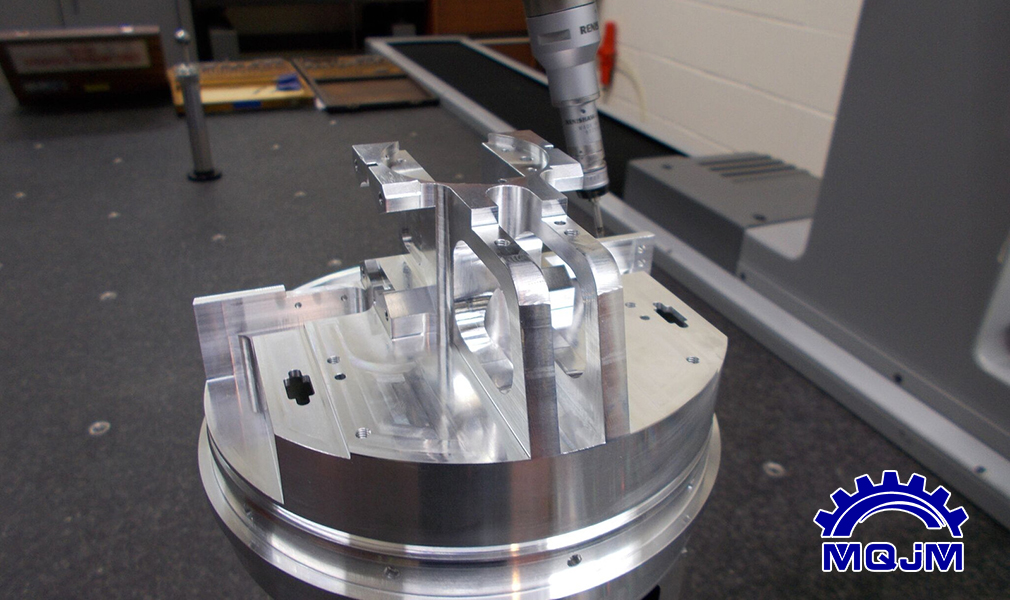

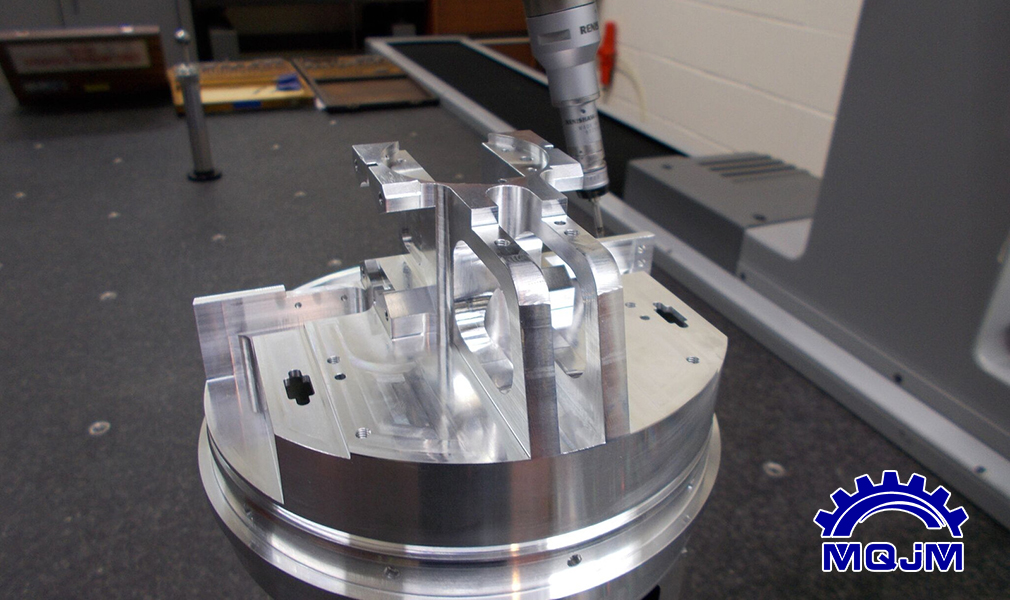

6. Inspection and Verification

a. In-Process Inspection

Use in-process inspection equipment to monitor the machining process in real-time:

- Probe Measurement Systems: Real-time measurement of workpiece dimensions and positions to ensure dimensional accuracy during machining.

- Laser Scanning: Scan the workpiece surface to detect surface quality and shape deviations, and adjust machining parameters timely.

b. Post-Process Inspection

Post-process inspection involves detailed measurement and verification of the machined workpiece:

- Coordinate Measuring Machine (CMM): High-precision measurement of workpiece geometric dimensions and shapes to ensure compliance with design requirements.

- Surface Roughness Tester: Measure the surface roughness of the workpiece to evaluate machining quality.

Summary

Handling complex shapes and surfaces in CNC milling requires comprehensive consideration of multiple factors, including tool selection, programming methods, machine accuracy, and process parameters. By optimizing tool paths, using coolants and lubricants, and implementing strict quality control and inspection measures, the final machining quality can be ensured efficiently and accurately. Continuous optimization of these aspects can significantly improve the efficiency and quality of machining complex shapes and surfaces to meet customer requirements.