China's CNC machining industry plays a crucial role in global manufacturing. With continuous technological advancements, Chinese CNC machining factories are capable of processing various steel materials, including many types of stainless steel and carbon steel. This article will introduce several common steel types used in CNC machining in China, such as 316 stainless steel, 304 stainless steel, 440C stainless steel, Q235 carbon steel, 40Cr alloy steel, tool steel, and spring steel, and discuss their applications in different CNC machining contexts.

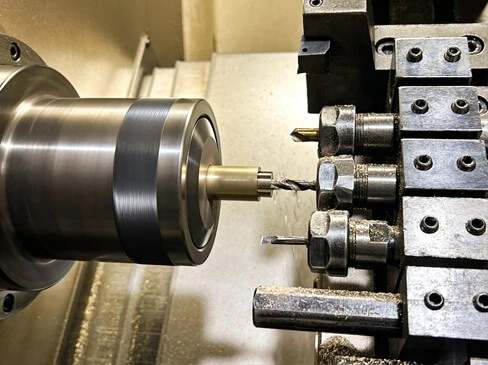

1. Carbon Steel CNC Machining

Material Overview: Carbon steel is one of the most widely used materials in CNC machining, especially in carbon steel CNC milling. With its strength and toughness, carbon steel offers great flexibility for manufacturing various industrial components.

Common Grades: Q235 carbon steel, 45 steel.

Application Scenarios: Q235 carbon steel CNC machining is commonly used to produce automotive parts, construction structures, and other components. Q235 is popular for its good machinability and economic efficiency.

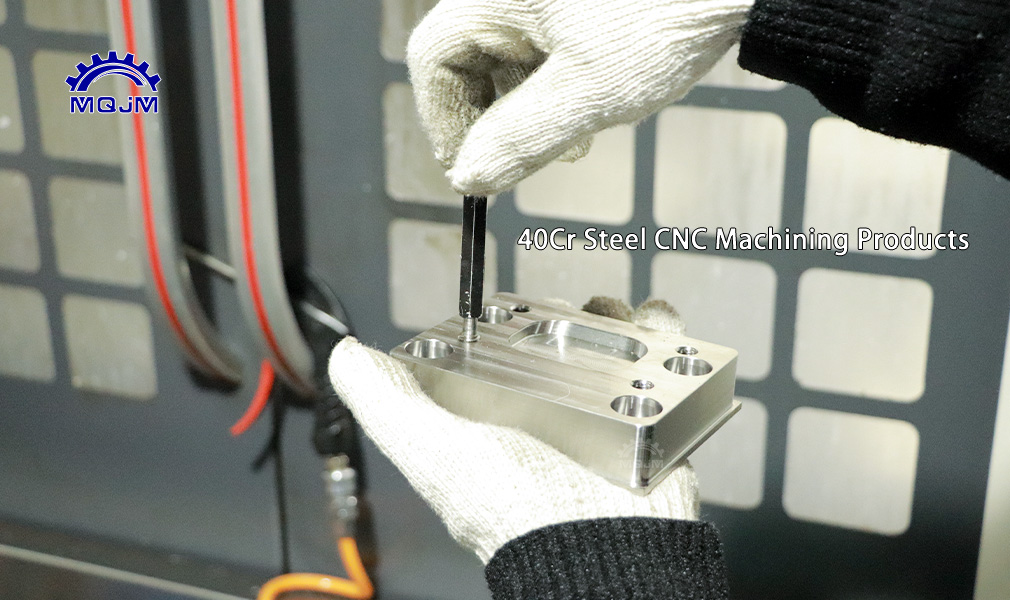

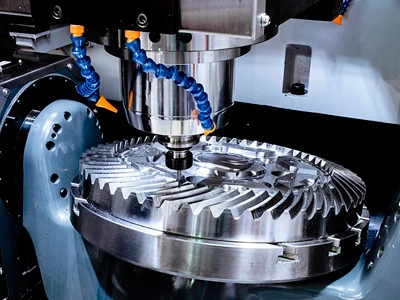

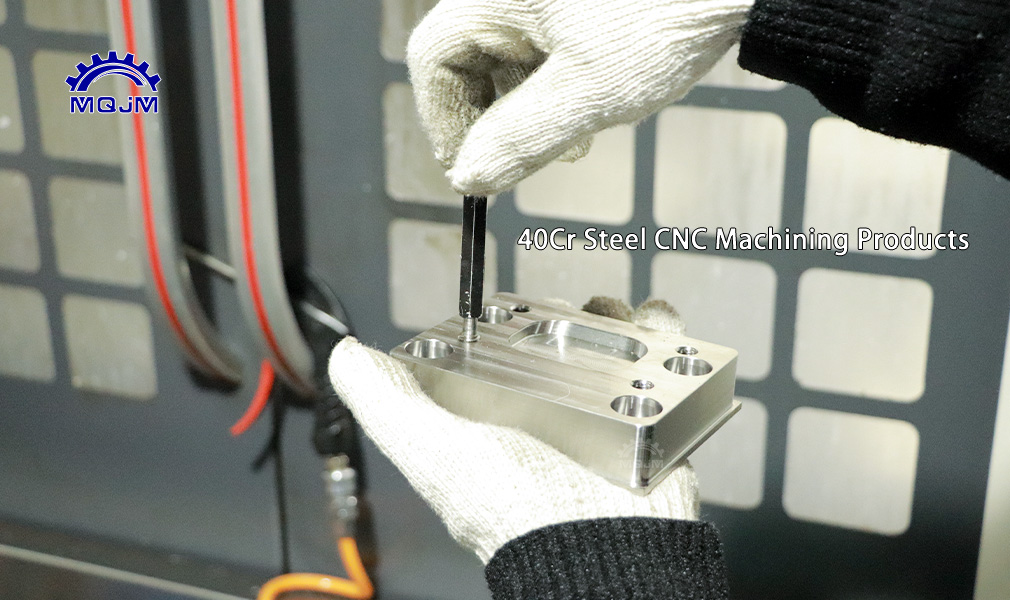

2. Alloy Steel CNC Machining

Material Overview: Alloy steel is enhanced by adding different alloying elements (such as chromium, nickel, and molybdenum) to improve its performance, particularly in high-strength and wear-resistant applications. 40Cr alloy steel CNC machining is especially common in such scenarios.

Common Grades: 40Cr, 42CrMo.

Application Scenarios: 40Cr alloy steel CNC machining is suitable for high-load mechanical parts such as gears, shafts, and more.

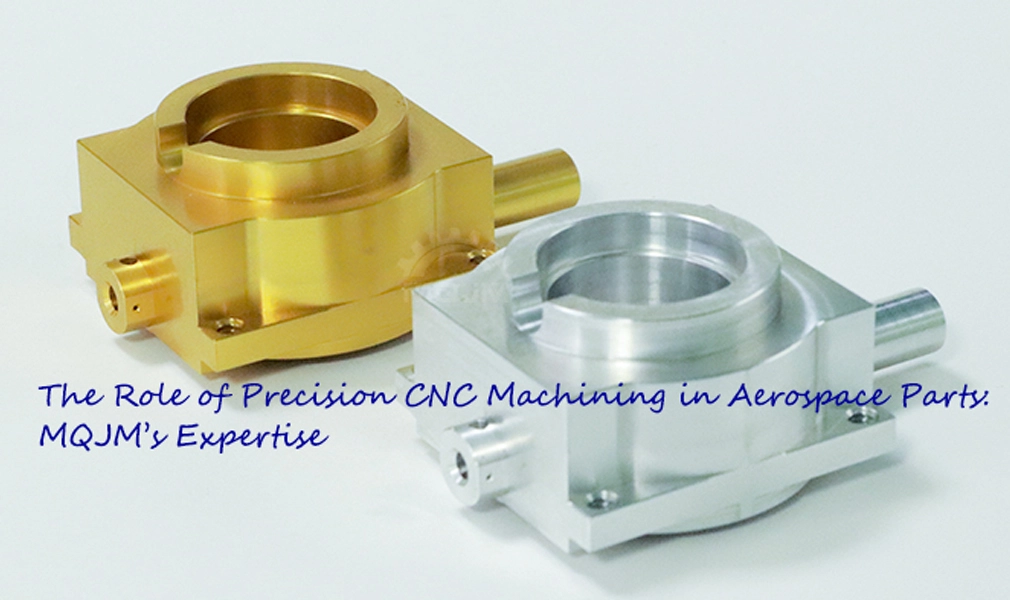

3. Stainless Steel CNC Machining

Material Overview: Stainless steel is a critical material in CNC machining, known for its exceptional corrosion resistance, particularly in precision and high-demand environments.

Common Grades: 304, 316, 440C.

Application Scenarios:

304 stainless steel CNC machining is widely used in food processing equipment, medical instruments, and other fields due to its excellent formability and corrosion resistance.

316 stainless steel CNC machining is more suitable for environments that demand higher corrosion resistance, such as chemical equipment, marine engineering, and medical devices.

CNC machining 440C stainless steel is ideal for parts requiring high hardness and wear resistance, such as knives, bearings, and precision tools. 440C is known for its high carbon content and excellent hardness.

4. Tool Steel CNC Machining

Material Overview: Tool steel is known for its high hardness, wear resistance, and performance under extreme conditions. CNC machining tool steel requires precise equipment and advanced processes.

Common Grades: D2, H13, SKD11.

Application Scenarios: Tool steel is often used for cutting tools, stamping dies, and plastic molds, where wear resistance is critical.

5. Spring Steel CNC Machining

Material Overview: Spring steel is characterized by its high strength and elasticity, making it suitable for handling impact and high mechanical loads.

Common Grades: 65Mn, 60Si2Mn.

Application Scenarios: Spring steel is used in the production of springs, elastic components, and impact-resistant parts. In CNC machining, careful consideration of its machinability is necessary to retain its elasticity and durability in practical applications.

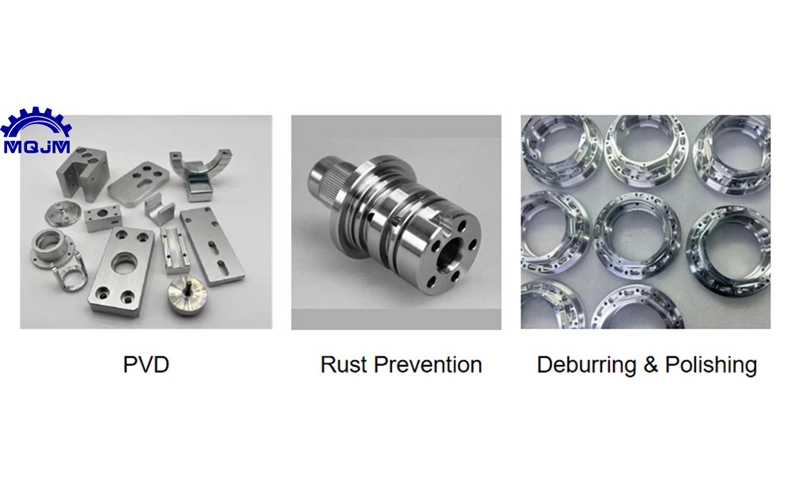

Chinese CNC machining factories have extensive capabilities, handling everything from carbon steel CNC machining to complex alloy steel CNC machining, as well as high-demand stainless steel CNC machining (including 304 stainless steel CNC machining, 316 stainless steel CNC machining, and 440C stainless steel CNC machining). Additionally, factories are equipped to process specialized materials like tool steel and spring steel. Choosing the right material is critical to enhancing product performance and longevity. Understanding the properties and applications of each material helps manufacturers make better decisions.