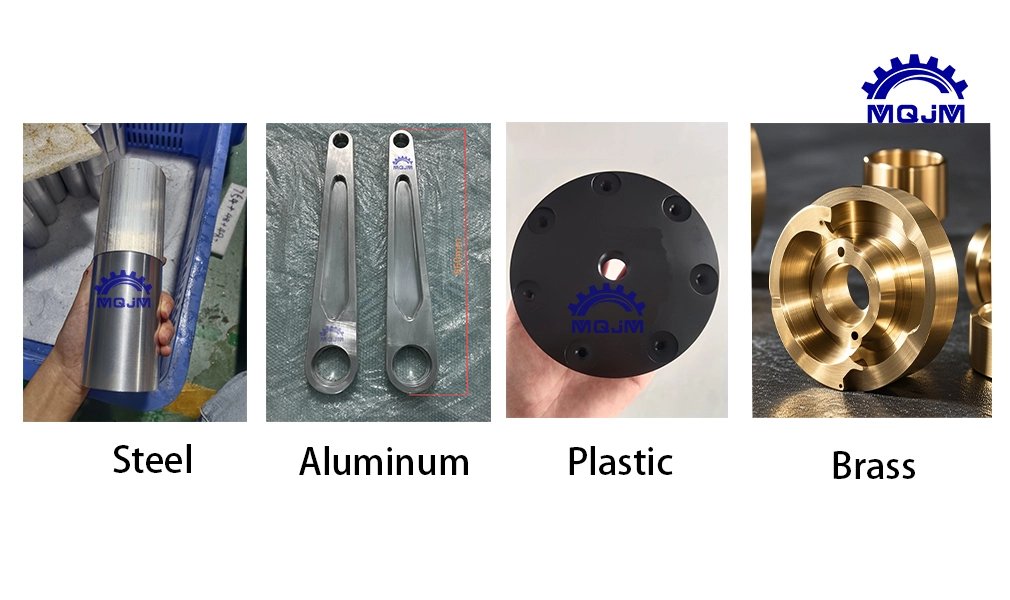

In our daily lives, many common aluminum products are actually manufactured using CNC (Computer Numerical Control) machining technology. These aluminum parts are not only visually appealing but also feature excellent durability and high precision. Today, let's take a look at some of the most common CNC aluminum parts in everyday life, which play important roles in various fields.

1. Bluetooth Speakers and Accessories

Many Bluetooth speaker housings and volume control knobs are made from aluminum alloy through CNC machining. These parts are typically treated with single-color or two-tone anodizing, enhancing their appearance and texture, while also improving the overall product's lifespan. CNC machining ensures that the precision and quality of aluminum parts are guaranteed, making Bluetooth speakers not only visually attractive but also more comfortable and durable to use.

2. Compact Cameras

You might not realize that most compact cameras' housings and accessories are actually made from anodized aluminum CNC parts. The lightweight nature of aluminum makes it the material of choice for cameras and camcorders, while the CNC machining process ensures superior precision and assembly fit. Anodized aluminum is not only corrosion-resistant but also provides a longer lifespan, offering a high-end, refined appearance that further increases consumer appeal.

3. Automotive Parts

Common automotive parts, such as handles, brake levers, and adjustment knobs, are often CNC-machined from aluminum alloy. Aluminum alloys are not only lightweight but, when processed using CNC techniques, these parts achieve high precision in structure. Whether it’s the grip of a handle, the feel of a brake lever, or the tactile sensation of an adjustment knob, CNC-machined aluminum parts offer exceptional precision and reliability, enhancing both comfort and safety while driving.

4. Fitness Equipment

Fitness equipment typically includes CNC-machined aluminum parts, especially for components that require friction. For example, anodized pink aluminum knurled handles for jump ropes and aluminum grips for resistance training are precisely manufactured aluminum alloy components. The knurling process increases friction and improves grip, providing better stability and enhancing the user's workout experience.

5. Lighting Fixtures

In modern lighting fixtures, aluminum alloy machined parts and components are widely used. Aluminum is lightweight and offers excellent heat dissipation, making it ideal for use as the housing or heat sinks of light fixtures. CNC machining allows these parts to be precisely shaped into complex structures, while also providing a refined finish that meets the aesthetic demands of modern home decor.

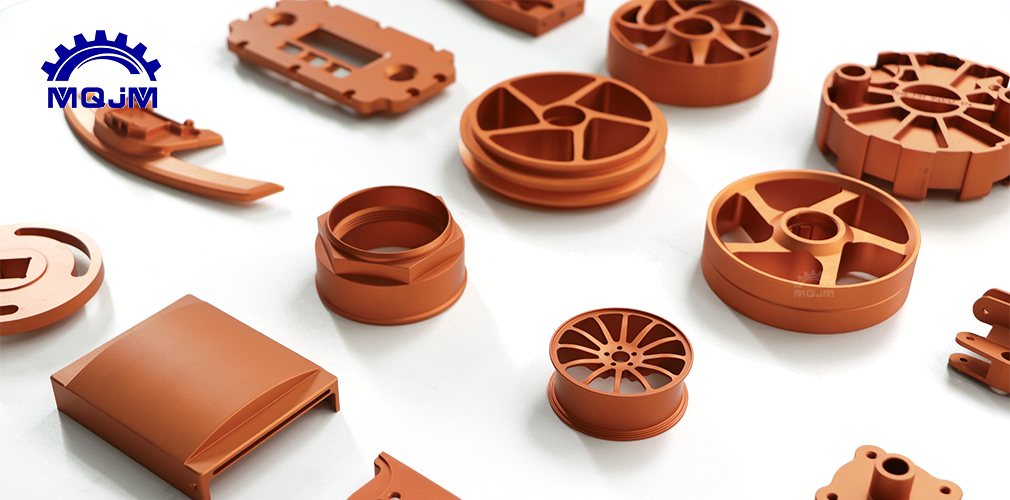

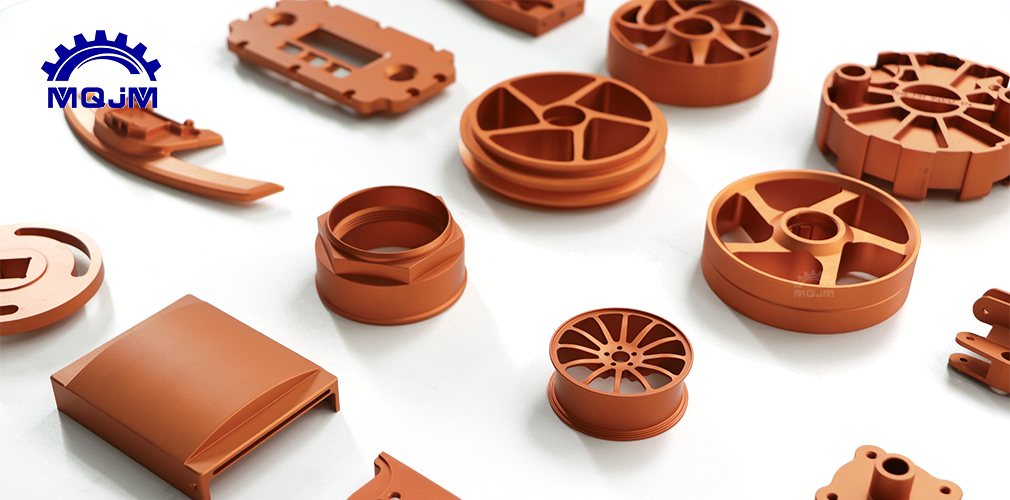

CNC aluminum parts are everywhere in our daily lives, with applications across various fields. If you need to customize high-quality aluminum products or precision aluminum housings and alloy parts, feel free to contact MQJM. They specialize in CNC machining of various parts and will provide you with the most professional aluminum milling service to meet your specific needs.