CNC racing parts refer to racing components manufactured or processed using CNC (Computer Numerical Control) technology. These parts are made using high-precision CNC machines, ensuring the performance, durability, and safety of the race car during high-speed operation. Below are some common types of CNC racing parts.

CNC Racing Parts: Engine Parts

Cylinder Head: CNC machined cylinder heads have smooth surfaces and precise passage designs, which can enhance combustion efficiency and engine performance.

Pistons: CNC machining ensures precise dimensions and shapes of pistons, reducing friction and increasing engine power.

Crankshaft: High-precision machined crankshafts can reduce vibration and improve engine balance and durability.

Camshaft: CNC machined camshafts can control the precise timing of valve opening and closing, optimizing engine power output.

CNC Racing Parts: Transmission System Parts

Gears: The gears in a race car's transmission need to be highly precise to ensure smooth shifting and efficient power transfer.

Differential Components: CNC machined differentials can provide better cornering performance for the race car, helping it smoothly navigate various track turns.

CNC Racing Parts: Suspension and Chassis Components

Control Arms: CNC machined control arms balance strength and light weight, capable of withstanding the immense pressure of high-speed turns.

Chassis Connectors: CNC machined connectors, through high-precision machining methods, can reduce vibrations during driving and increase overall rigidity.

CNC Racing Parts: Brake System Parts

Brake Discs: High-strength, high-temperature resistant materials processed through CNC machining can ensure the durability and heat dissipation of brake discs, helping to quickly reduce speed during races.

Brake Calipers: Precisely CNC machined brake calipers can maintain stable braking performance under extreme conditions.

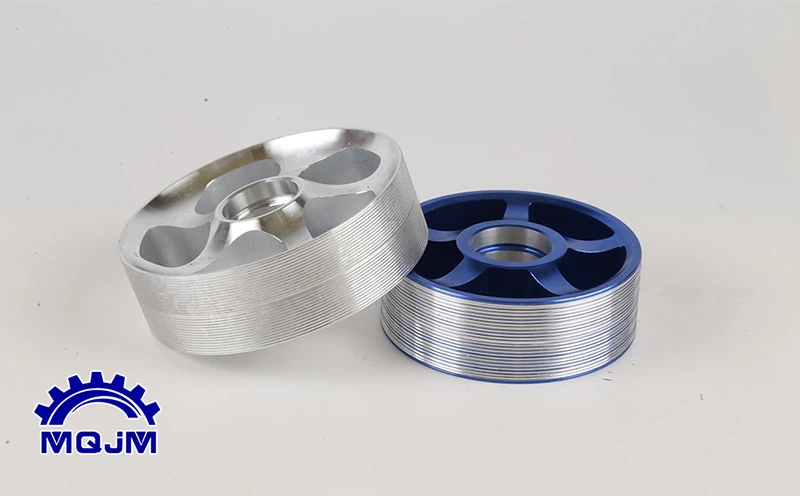

CNC Racing Parts: Wheel Hubs and Body Components

Wheel Hubs: Wheel hubs processed using CNC technology are not only lightweight but also strong, capable of withstanding massive impacts during high-speed travel.

Aerodynamic Components: Parts such as front and rear spoilers need to be CNC machined to ensure precise design, maximizing the race car's aerodynamic performance.

CNC Racing Parts: Fuel System Components

Fuel Injectors: CNC machined fuel injectors can precisely control the amount and angle of fuel injection, thus optimizing the fuel-air mixture and improving combustion efficiency.

CNC Racing Parts: Electronic System Installation Parts

Sensor Brackets: Brackets used to install and protect various sensors can be custom-machined using CNC to ensure precise installation and prevent damage.

CNC technology plays a crucial role in the manufacturing of racing parts. It not only allows the realization of highly complex designs but also improves production efficiency while ensuring parts' precision. Additionally, CNC machined parts offer greater flexibility in material selection, meeting the high requirements of racing for weight, strength, and durability.