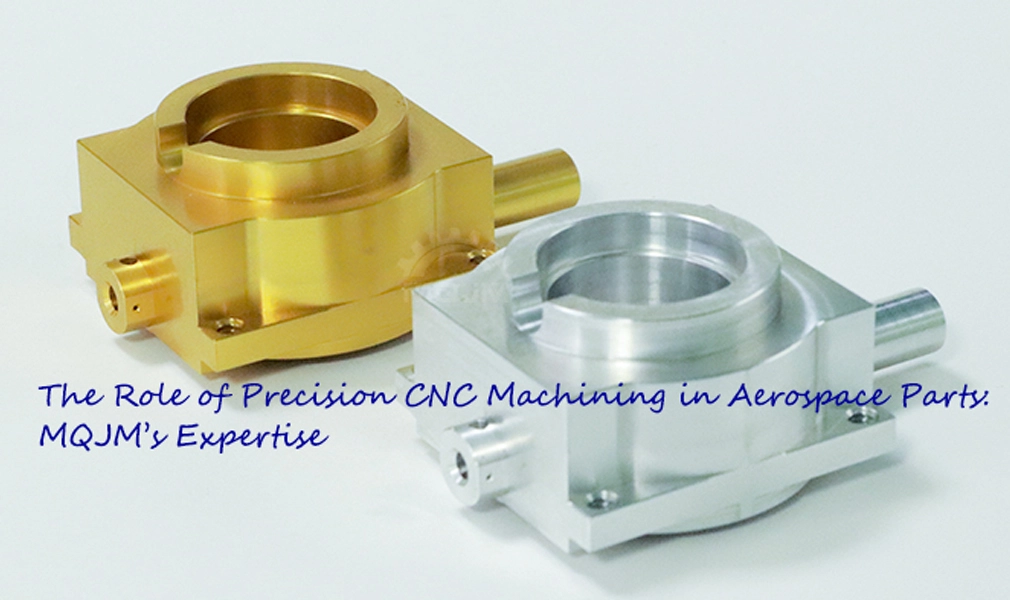

In the field of CNC machining, 6061 aluminum stands out as the material of choice for many industries. Its excellent combination of strength, lightweight and corrosion resistance makes it ideal for applications ranging from aerospace to automotive. At MQJM, we understand the importance of ensuring the highest quality of 6061 aluminum machining.

Quality control is not just a simple word; It's the backbone of our business. From the moment we receive a batch of 6061 aluminum, to the final inspection of the custom CNC machined parts, every step is carefully monitored and controlled. Our dedicated team of engineers and technicians are committed to delivering products that meet and exceed customer expectations.

The inspection process begins with a thorough inspection of the raw materials. We check for any defects or inconsistencies that may affect the quality of the process or the final product. This includes measuring hardness, checking for impurities, and ensuring the correct 6061 aluminum composition. Only materials that pass our strict quality checks are used during processing.

In the process of machining, we use professional technology and advanced processing technology to ensure precision and accuracy. Our modern CNC machines are capable of producing complex geometrics with tight tolerances, ensuring that each part is manufactured to the exact specifications required by the customer. We also use advanced cutting tools and lubricants to minimize tool wear and improve surface finish.

Continuous monitoring is a key aspect of our quality control process. Our technicians regularly check machining parameters such as cutting speed, feed speed and cutting depth to ensure optimum performance. Any deviations from the set parameters are dealt with immediately to prevent defects and ensure consistent quality.

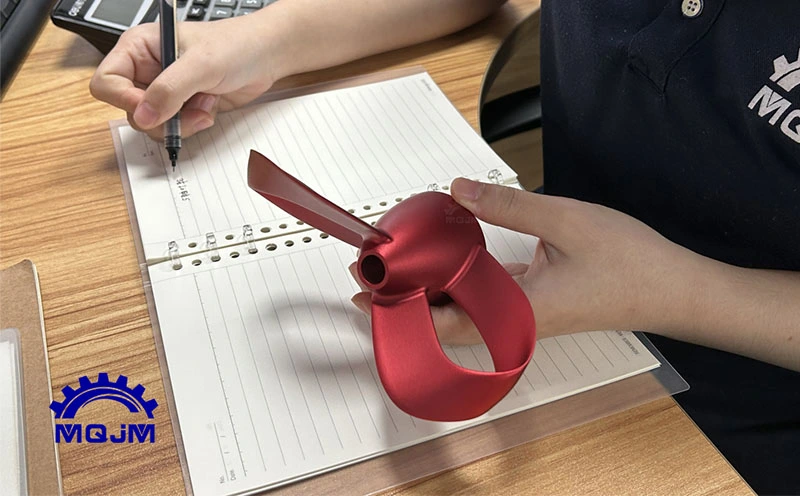

Once the machining process is complete, a comprehensive final inspection is carried out. This includes measuring the dimensions of the parts using precision measuring instruments, checking the surface roughness, and checking for any visible defects. We also perform functional tests on some components to ensure that they meet the required performance standards.

At MQJM, we pride ourselves on our commitment to quality. Our rigorous inspection and control process ensures that every 6061 aluminum machined part leaving our facility is of the highest quality. Whether it is a small part for a high-tech device or a large structural part for an aircraft, you can trust MQJM to provide exceptional CNC precision machining service.

In short, when it comes to machining 6061 aluminum, MQJM is the name you can rely on, with very high quality and precision. We are committed to quality control and inspection to ensure that our products meet the highest standards in the industry. Contact us today to experience the difference that high quality machining can make.