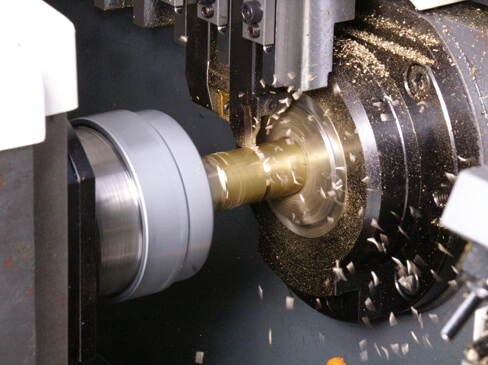

Stainless steel CNC machining, as a widely used metal processing technology, holds a significant position in various industries due to its unique material properties. However, the characteristics of stainless steel, such as high hardness, high toughness, and strong corrosion resistance, impose more stringent requirements on CNC machining equipment and tools. This article aims to delve into the characteristics of stainless steel CNC machining and provide practical advice on the selection of milling cutters based on these characteristics.

Characteristics of Stainless Steel CNC Machining

High Hardness

The hardness of stainless steel is significantly higher than that of ordinary metals. This means that during the machining process, the cutting tools need to withstand greater cutting forces and friction, thereby requiring higher wear resistance.

High Toughness

The toughness of stainless steel makes it difficult to be easily cut, and it tends to produce long, continuous chips during machining, increasing tool wear and machining difficulty. Therefore, appropriate cutting parameters and tool designs are needed to effectively manage the chips.

Strong Corrosion Resistance

The corrosion resistance of stainless steel can accelerate tool corrosion and wear during machining, especially when the machining environment contains moisture, acidic, or alkaline substances. Therefore, tool materials must possess excellent corrosion resistance.

Selection of Milling Cutters

Tool Material

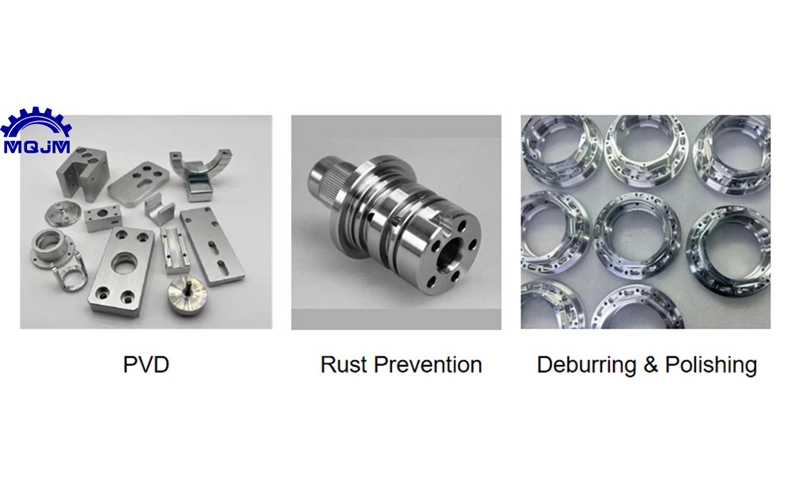

Carbide Tools:Featuring high hardness and wear resistance, carbide tools are a common choice for processing stainless steel. Especially carbide tools with coatings such as PVD (Physical Vapor Deposition) coatings can further enhance the tool's wear resistance and corrosion resistance.

Ceramic Tools: Under certain conditions, ceramic tools, known for their extremely high hardness and good chemical stability, are also suitable for stainless steel machining. However, their high brittleness must be noted, and they are not suitable for all machining scenarios.

Tool Geometry

Rake Angle and Clearance Angle: Choosing tools with larger rake angles and clearance angles can reduce cutting force and friction, lower cutting temperature, and thereby extend tool life and improve machining efficiency.

Tool Coatings

Common coatings such as TiN (Titanium Nitride), TiCN (Titanium Carbonitride), and AlTiN (Aluminum Titanium Nitride) can effectively reduce the friction coefficient between the tool and the workpiece, reduce cutting heat, and prevent issues such as tool sticking and thermal cracking. Additionally, coatings provide extra corrosion resistance, protecting the tool from stainless steel material erosion.

Cutting Parameters

Reasonable selection of cutting speed, feed rate, and cutting depth is crucial for ensuring machining quality and tool life. Generally, for stainless steel machining, lower cutting speeds and higher feed rates, along with appropriate cutting depths, are required to achieve optimal machining results.

Conclusion

Stainless steel CNC machining is a task with both challenges and opportunities. To achieve the best machining results, it is essential to consider the material properties of stainless steel comprehensively, choose the appropriate milling cutter materials, geometries, and coatings, and carefully adjust cutting parameters. By continually optimizing these elements, machining efficiency can be significantly improved, production costs reduced, and tool life extended. Therefore, for technicians engaged in stainless steel CNC machining, mastering this knowledge and these skills is crucial.