In modern manufacturing, 5 Axis CNC Machining Services have become a new standard. This technology not only improves production efficiency but also greatly enhances the precision and quality of parts. Below, as a professional CNC precision machining manufacturer, we will delve into the advantages, applications, and future development trends of 5 Axis CNC Machining Services.

I. Advantages of 5 Axis CNC Machining Services

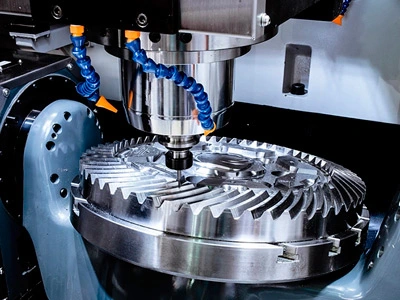

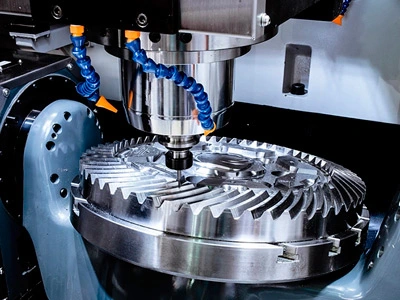

The biggest advantage of 5 Axis CNC Machining Services lies in its high efficiency and precision. Traditional machining methods require multiple positioning and clamping, while CNC 5-axis machining can complete all machining processes after one positioning, greatly improving production efficiency, realize rapid CNC machining. At the same time, due to the reduction of manual operations, the occurrence of errors is also reduced, improving the precision and quality of parts. In addition, CNC 5-axis machining also has powerful processing capabilities. It can handle complex surfaces and space curves, allowing designers to be more free in design, not limited by processing capabilities.

II. Application of 5 Axis CNC Machining Services

The application of 5 Axis CNC Machining Services is very wide, almost covering all manufacturing industries. In aerospace, automotive and racing, medical equipment, energy, optics, and other fields, CNC 5-axis machining plays an important role.

For example, in the aerospace field, CNC 5-axis machining can accurately manufacture complex parts, such as turbine blades, aerospace engine casings, etc. In the automotive and racing manufacturing industry, CNC 5-axis machining can quickly and accurately manufacture car and racing parts, such as hubs, engine parts, cylinders, etc.

III. Future Development Trend of 5 Axis CNC Machining Services

With the development of technology, the future development trend of 5 Axis CNC Machining Services will become more apparent. Firstly, with the development of artificial intelligence and machine learning technology, CNC 5-axis machining will become more intelligent, able to automatically optimize the machining process, improve production efficiency and part quality.

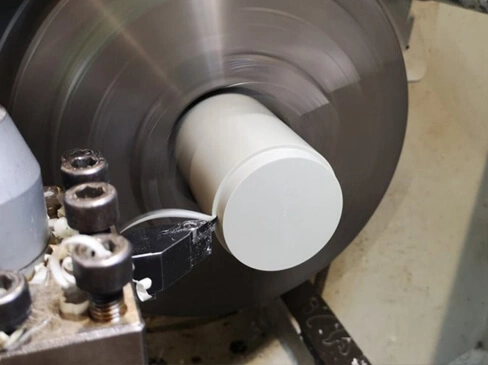

Secondly, with the development of new materials, CNC 5-axis machining will be able to handle more types of materials, such as high-strength steel, super-hard materials, etc., further expanding its application fields.

Finally, with the development of digitization and networking, CNC 5-axis machining will achieve remote control and monitoring, improving the flexibility and efficiency of production.

Conclusion

CNC 5-axis machining services have become a new standard in modern manufacturing, and its high efficiency, high precision, and powerful processing capabilities have made it widely used in various fields. With the development of technology, the future development trend of 5 Axis CNC Machining Services will become more apparent, further promoting the development of the manufacturing industry.