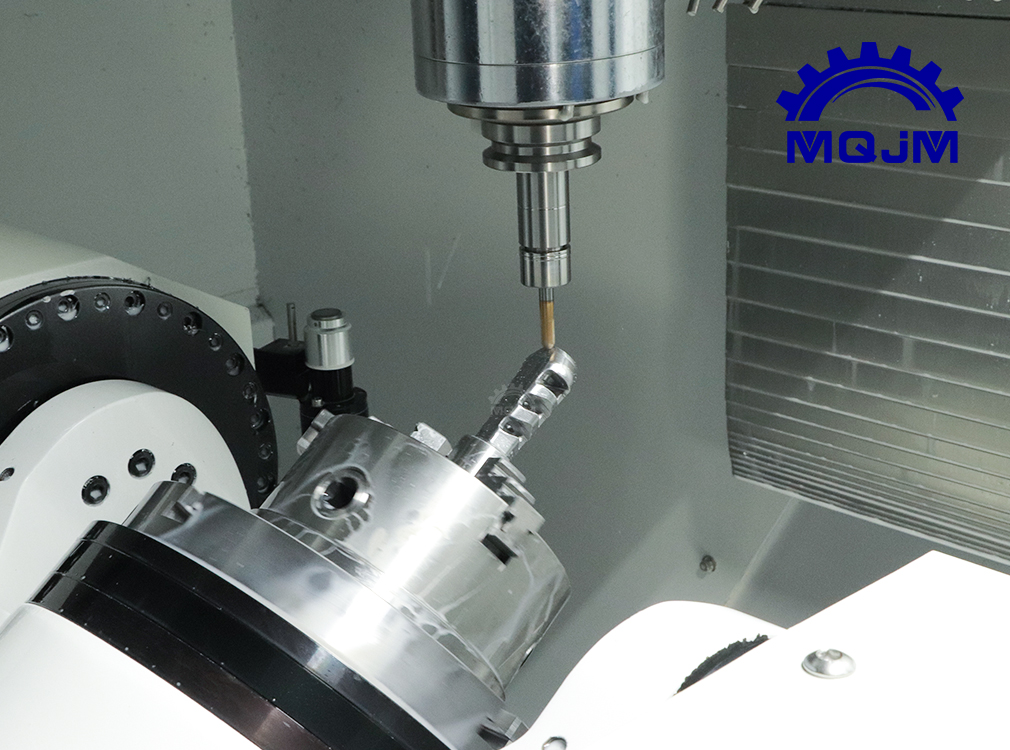

As an experienced steel CNC machining factory, we not only provide high-precision steel CNC machining services but also offer suitable surface treatment machining for each part to ensure product performance, appearance, and durability. Through our advanced steel CNC machining technology, we can apply various surface treatment methods to meet different application requirements, enhancing the corrosion resistance, hardness, and aesthetic appeal of steel parts.

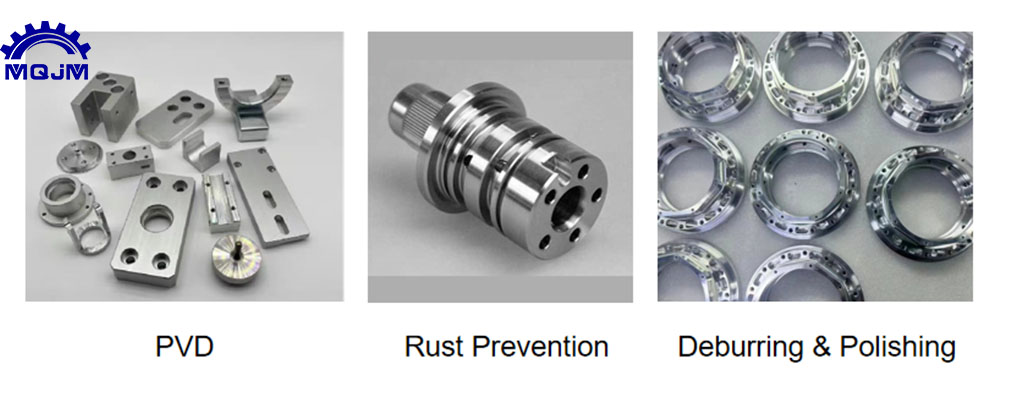

Common Surface Treatment Machining for Steel CNC Machining:

1.Black Oxide: In steel CNC machining, black oxide machining forms an oxide layer on the steel surface through a chemical reaction, effectively preventing oxidation, enhancing the part’s corrosion resistance, and providing a professional matte black finish, ideal for the protection and decoration of mechanical parts.

2.Heat Treatment: Heat treatment is an essential process in steel CNC machining, altering the physical properties of steel through heating and cooling. It significantly improves the hardness and wear resistance of parts, extending their service life, which is especially important for parts with high strength requirements.

3.Electroplating: During the steel CNC machining process, electroplating can be applied to add a metal coating, such as zinc or nickel, to the steel surface. This forms an effective corrosion-resistant layer, enhancing the durability and oxidation resistance of the steel, particularly in parts used in humid or corrosive environments.

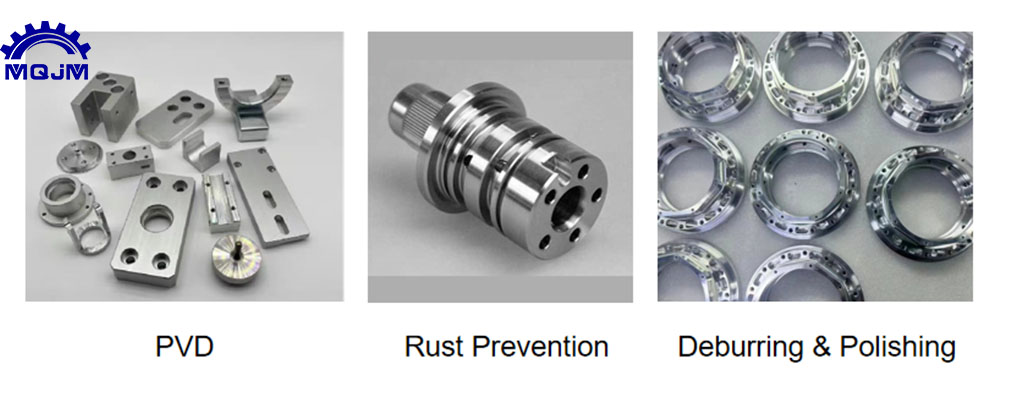

4.Vacuum Coating (PVD): Vacuum coating is a surface treatment often used in steel CNC machining for producing more wear-resistant and corrosion-resistant surfaces, while also giving parts a decorative and refined appearance. This process is more environmentally friendly than traditional plating methods and is ideal for high-demand decorative and

functional parts.

5.Rust Prevention: For steel parts produced through steel CNC machining, we offer various rust prevention machining to ensure long-term use in outdoor or humid environments, extending the lifespan of parts by protecting them from rust.

6.Deburring & Polishing: In steel CNC machining, deburring and polishing are key steps to ensure parts have smooth edges and a comfortable hand feel. This process enhances the overall appearance of parts, especially for applications where appearance and touch are critical.

By combining our professional steel CNC machining capabilities with a wide range of surface treatment machining, you can obtain high-precision steel parts that not only meet strict specifications but also deliver excellent durability, performance, and aesthetic appeal. Whether you're looking for enhanced corrosion resistance, improved hardness, or a more polished finish, our steel CNC machining solutions are customized to meet your specific needs.