Introduction of CNC Machined Custom Copper Parts

Copper CNC machining is the primary process for producing custom copper parts in many industries. Due to copper's excellent ductility, electrical conductivity, and thermal conductivity, CNC machined custom copper parts are widely used in automotive, aerospace, medical, and many other industries.

Precautions for Copper CNC Machining

Selecting the Right Copper

Copper is one of the most expensive materials, so selecting it requires considering both application characteristics and cost-effectiveness.

Setting the Feed Rate

The feed rate is the speed at which the cutting tool engages with the workpiece. Therefore, before machining CNC custom copper parts, it is essential to set the correct feed rate, as it affects the quality, life span, and surface finish of the custom copper parts. Additionally, copper's efficient heat conduction means high feed rates can increase tool wear over time.

Design for Manufacturability

Before machining CNC custom copper parts, it is necessary to organize design requirements and specifications, which helps achieve the functionality of CNC custom copper parts. This includes reducing the number of part setups, size checks, and preventing small radius deep cavities.

Selecting the Right Tool Material

Many bronze plates are softer to machine than aluminum and steel of equivalent strength, which can lead to blade formation and tool wear. Therefore, choosing the right tool material is crucial. High-speed steel is one appropriate tool material for copper CNC machining.

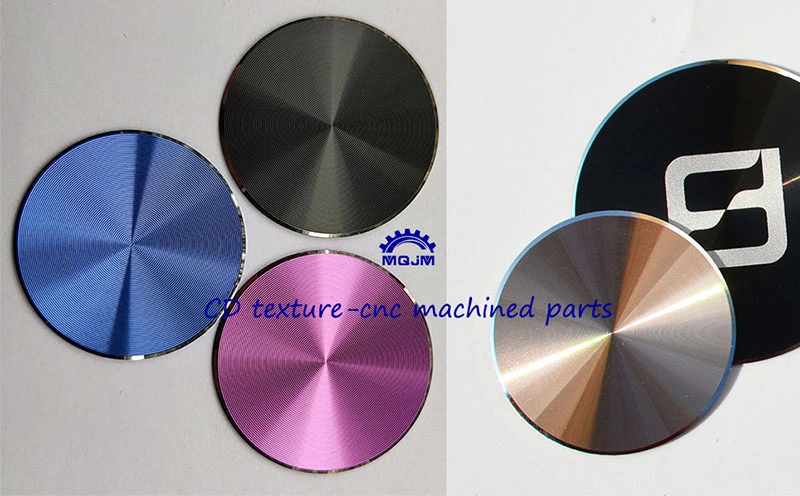

Surface Treatment

Electrolytic Polishing

Copper can be polished electrolytically to achieve a very smooth and shiny surface. Electrolytic polishing can further improve the corrosion resistance of custom copper parts without affecting their conductivity.

Electroplating

Metal electroplating of copper can maintain both electrical and thermal conductivity, often helping to prevent oxidation on the surface of custom copper parts. In particular, noble metal electroplating (such as silver or gold plating) can provide low contact resistance to maintain excellent electrical conductivity and welding performance.

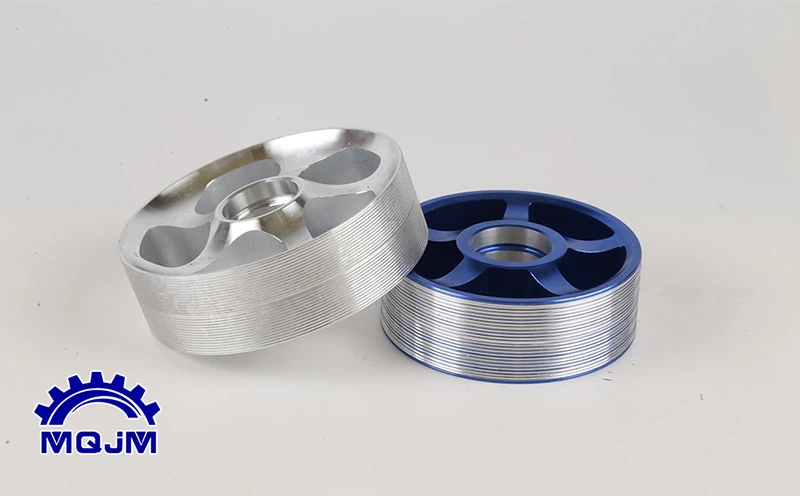

Why Choose MQJM's CNC Machined Custom Copper Parts?

MQJM has 13 years of experience in custom CNC machining services for copper , and the CNC machined custom copper parts processed by MQJM can meet the needs of the electronics, aerospace, and other industries. Through professional surface treatment, the customized copper parts provided by MQJM are not only attractive but also have excellent corrosion resistance. As one of the professional custom CNC precision machining suppliers in China, MQJM, with its advanced technology and optimized processes, can efficiently meet customer needs and provide high-quality CNC machined custom copper parts.