In the dynamic world of the automotive industry, every component plays a crucial role in ensuring the performance, safety, and efficiency of vehicles. One such significant element is aluminum turning parts. These precision-engineered components are transforming the way cars are built and are becoming an integral part of modern automotive manufacturing.

Aluminum has long been recognized for its lightweight yet durable properties. In the automotive context, this means lighter vehicles that consume less fuel and produce fewer emissions. Aluminum turning parts contribute significantly to achieving these goals. From engine components to transmission systems and various structural elements, these parts are designed to meet the demanding requirements of the automotive sector.

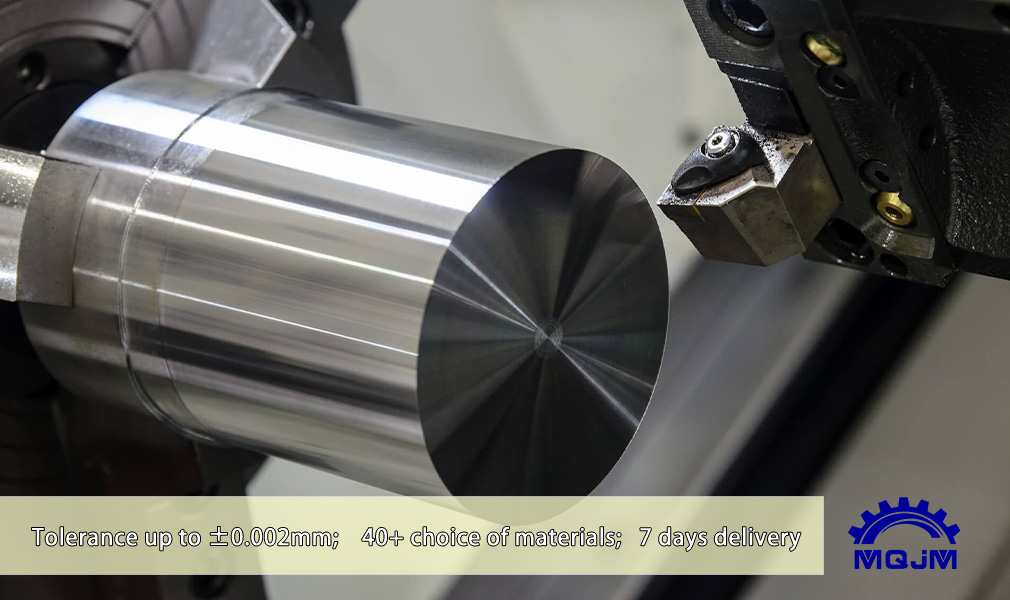

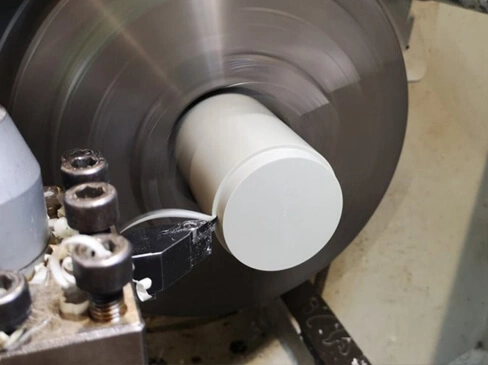

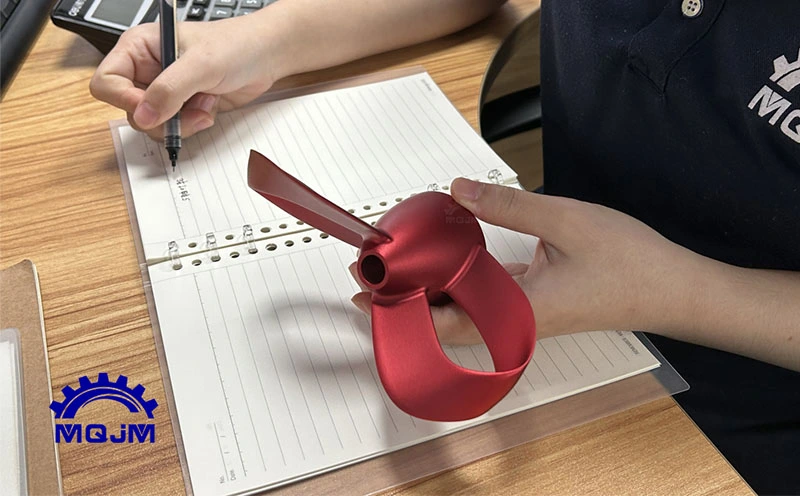

The manufacturing process of aluminum turning parts is a combination of advanced technology and craftsmanship. CNC machining ensures precise dimensions and smooth surfaces, resulting in parts that fit perfectly and perform reliably. Skilled machinists use state-of-the-art equipment to turn raw aluminum into intricate and functional components.

One of the key advantages of aluminum turning parts in the automotive industry is their ability to enhance vehicle performance. Lighter weight means improved acceleration, better handling, and reduced wear and tear on other components. For example, aluminum engine blocks are not only lighter but also offer better heat dissipation, leading to more efficient engine operation.

In addition to performance benefits, aluminum turning parts also contribute to the overall safety of vehicles. High-quality parts are designed to withstand the rigors of daily driving and provide reliable functionality in critical situations. Whether it's a brake component or a suspension part, the integrity and durability of aluminum turning parts are essential for ensuring the safety of drivers and passengers.

The automotive industry is constantly evolving, and aluminum turning parts are at the forefront of this innovation. As manufacturers strive to meet stricter environmental regulations and consumer demands for more efficient and sustainable vehicles, the use of aluminum turning parts is expected to continue to grow.

Moreover, the development of new alloys and manufacturing techniques is further expanding the possibilities for aluminum turning parts. Advanced materials are being developed that offer even greater strength and durability while maintaining the lightweight advantage of aluminum.

In conclusion, aluminum turning parts are a vital component of the automotive industry. Their lightweight, durable, and precision-engineered nature makes them an essential part of modern vehicle manufacturing. As the industry continues to advance, these parts will play an even more significant role in driving innovation and sustainability. So, keep an eye on the world of aluminum turning parts as they continue to shape the future of the automotive industry.