With the rapid development of the aerospace, communications, electronics, and medical device industries, traditional processing techniques can no longer meet the diverse, large-scale, and complex demands for processing precision stainless steel parts. The processing industry is swiftly moving towards high efficiency, precision, and compound processing.

Stainless steel is a very common material that is difficult to process. Achieving high-efficiency milling of stainless steel is a technical issue that many factories are concerned about.

Characteristics of CNC Stainless Steel Machining

High hardness

Stainless steel generally has high hardness, which requires cutting tools with high wear resistance.

High toughness

Stainless steel materials have good toughness, so they can easily produce clogging chips during CNC processing. This requires appropriate selection of cutting parameters and reasonable tool design.

Strong corrosiveness

Stainless steel is highly corrosive, which can easily cause issues like corrosion and wear on tools. Therefore, selecting corrosion-resistant tools is very important.

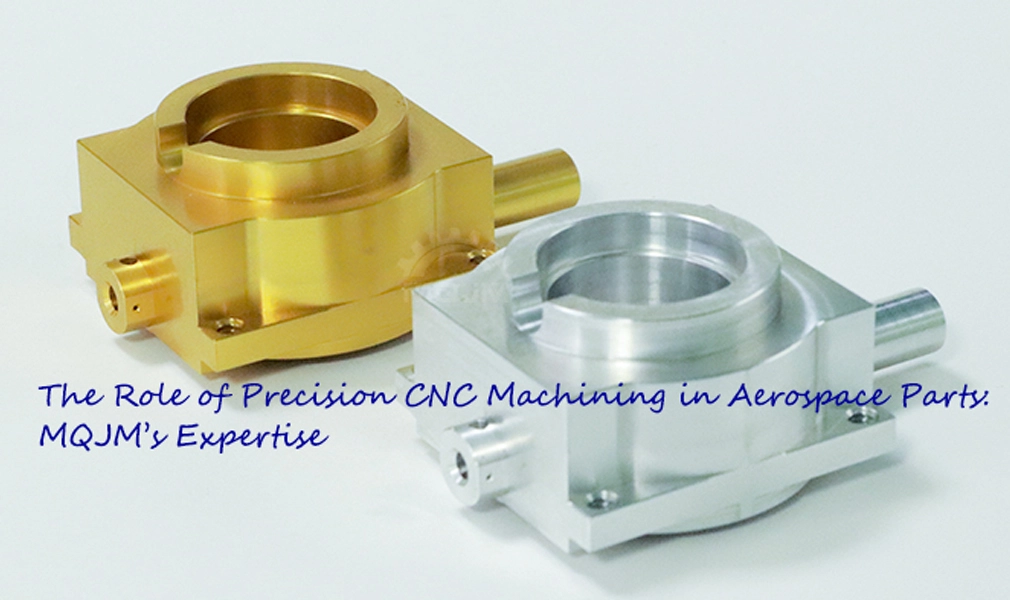

Reasons to Choose MQJM for CNC Milling Stainless Steel Parts

Rich experience

As one of leading custom cnc precision machining suppliers, MQJM has 13 years of extensive experience and is dedicated to providing users with high-quality CNC milling stainless steel parts services.

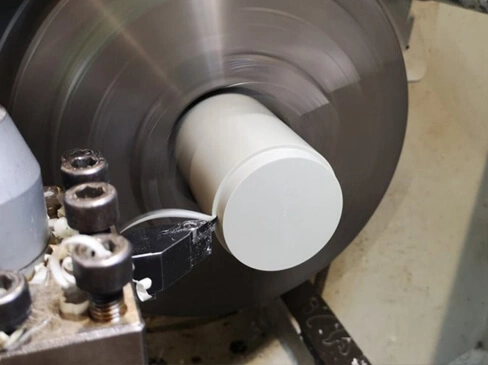

Advanced processing technology

MQJM uses advanced 3, 4, and 5-axis CNC processing technology to manufacture custom CNC milling stainless steel parts with excellent mechanical properties, high precision, and repeatability.

Customized services

MQJM can also produce high-quality custom CNC milling stainless steel parts for complex projects with very high precision and tolerance, meeting the required technical specifications while saving time and cost.

Quality assurance

MQJM also uses advanced multi-axis stainless steel CNC machines for part processing to ensure the best quality and accuracy of CNC milling stainless steel parts during our China cnc milling service.