4 Axis CNC Machinng Serivces

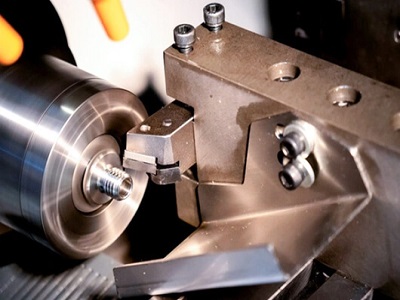

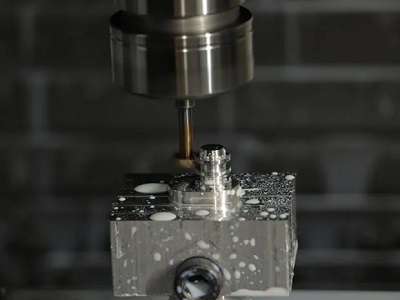

CNC 4-axis machining is a processing method that uses computer numerical control technology. The machine tool has four axes of motion: X, Y, Z and a rotation axis (commonly called the A-axis). This configuration allows movement in three linear directions and rotation around a rotational axis for more complex and precise part machining, especially for complex geometries requiring multi-axis motion.

Mingqiang Precision has more than 40 advanced CNC machining machines, including 30 3-axis and 4-axis CNC machining machines. Our processing machines are efficient 24 hours a day, allowing us to meet our customers' production needs for fast delivery.

At the same time, As a leading CNC machining factory, MQJM is committed to innovation and advanced technology, ensuring that we meet the complex geometry and high precision requirements of 4-axis CNC machining.