In modern manufacturing, high-precision CNC milling has become one of the core technologies for achieving high-quality, high-efficiency machining. Whether in aerospace, automotive industry, medical devices, or mold manufacturing, more and more enterprises are relying on CNC milling technology to meet the part processing needs of complex structures and stringent accuracy requirements.

The Working Principle of High-Precision CNC Milling

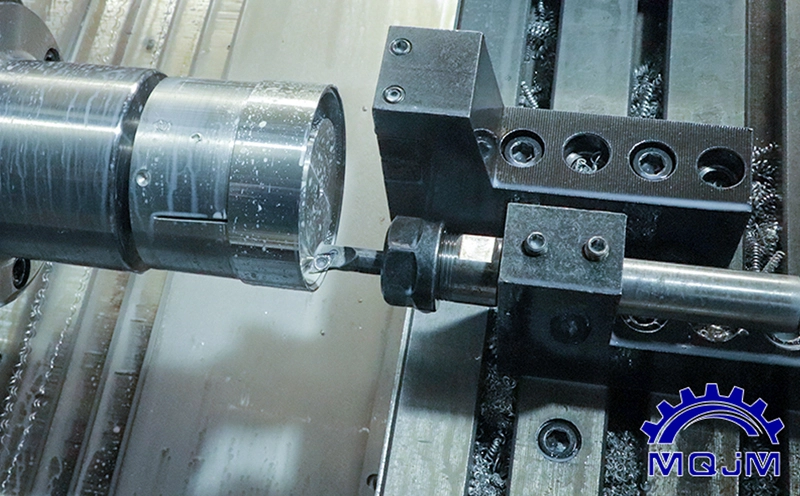

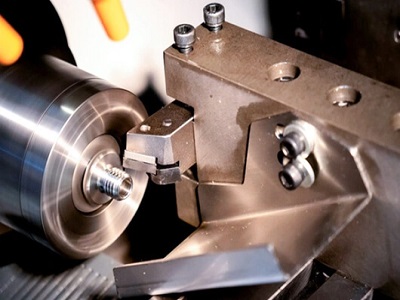

High-precision CNC milling involves the milling machine processing surfaces usually composed of lines, arcs, or other curves. Generally, milling machine operators continuously adjust the relative position between the tool and the workpiece according to the requirements on the drawings and match it with the selected milling cutter speed, thus achieving the milling of the workpiece. Parts can be machined into various shapes as needed.

CNC milling machine processing decomposes the movement coordinates between the tool and the workpiece into the smallest unit, which is the smallest displacement. Then, through multiple minimal displacements of each coordinate by the numerical control system, the relative movement between the tool and the workpiece is completed to achieve machining.

The Composition and Advantages of CNC Milling Machines

Modern CNC milling machines, also known as CNC milling machines, are optimized and upgraded based on traditional manual milling machines. They can be divided into ordinary CNC milling machines and CNC machining centers depending on whether they are equipped with a tool magazine or not. Their basic structure includes: bed, milling head, table, transverse feed system, lifting platform, and complete cooling and lubrication devices.

In terms of structural design, CNC milling machines are highly integrated, suitable for processing small to medium-sized, complex curved parts. They have strong adaptability, high accuracy, and good stability. Especially in scenarios involving the processing of small parts with a table width not exceeding 400mm, they exhibit excellent performance.

Precision Control Methods in High-Precision Cnc Milling

To ensure the processing quality of parts in high-precision CNC milling, the following aspects can be considered:

Blank clamping reference surface positioning: Reasonably choosing and stabilizing the clamping reference surface, ensuring the repeatability and consistency of workpiece clamping, is the first step in ensuring accuracy.

Equipment temperature control management: During long-term processing, CNC milling machines are prone to thermal deformation, affecting accuracy. By controlling the ambient temperature or using the equipment's own heat dissipation measures, the impact of temperature rise can be effectively reduced.

Error compensation technology: During processing, using the CNC system to dynamically compensate for errors, such as pitch errors and tool wear errors, further enhances machining accuracy.

With the continuous development of industrial intelligence, high-precision CNC milling is not only a reflection of manufacturing process upgrades but also a key to enhancing the core competitiveness of enterprises. Faced with the challenges of manufacturing higher quality and more complex structures of parts, high-precision CNC milling provides a reliable solution.

Take MQJM's aluminum CNC milling service as an example. It focuses on high-precision, small-batch, and customized aluminum part processing. Relying on advanced CNC equipment and rich engineering experience, it can achieve micron-level machining accuracy and perfect restoration of complex geometric shapes, providing customers with reliable, stable, and efficient aluminum alloy processing solutions. In fields with extremely high quality requirements such as aerospace, new energy, and precision instruments, MQJM has become the preferred processing partner for many customers.