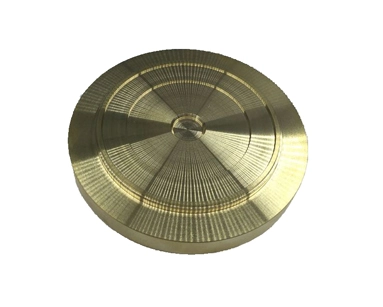

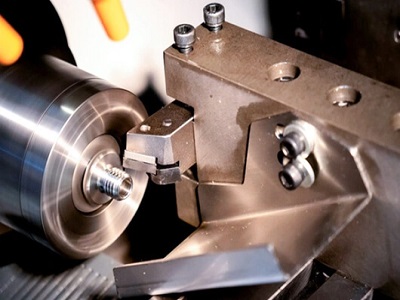

Brass Turning Parts

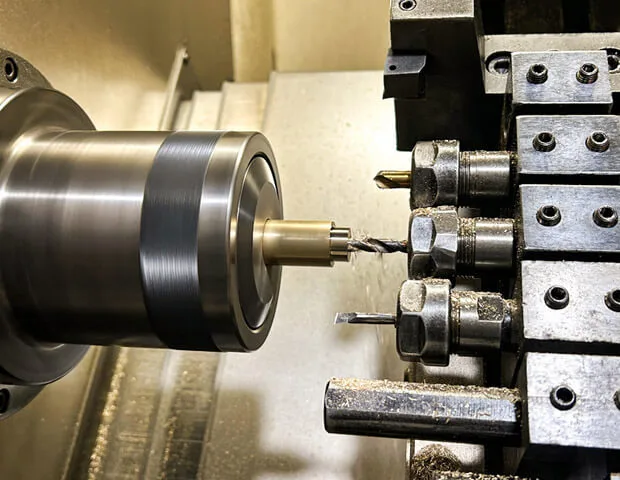

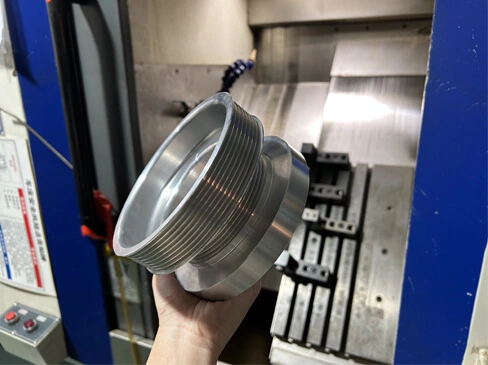

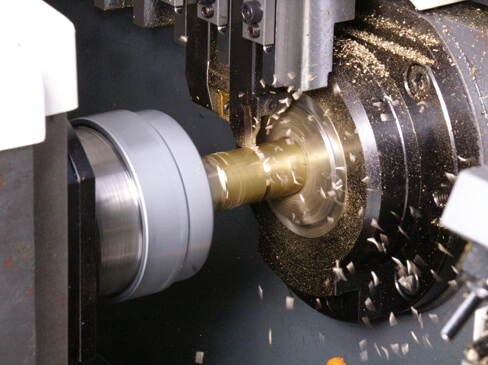

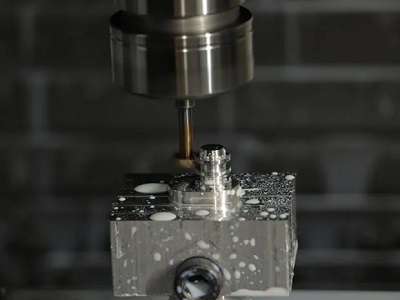

CNC brass turning from MQJM is a process of precision cutting of brass materials through computer numerical control (CNC) technology. This involves using an automated CNC lathe or turning center to accurately machine the shape, size and surface properties of brass workpieces according to predetermined procedures and design specifications. MQJM‘s CNC brass turning services can be used to produce a variety of brass parts for applications requiring high precision and complex shapes, such as electronics, aerospace and manufacturing.

As one of the most professional brass turning parts manufacturers with 13 years experience, MQJM is able to ensure that every brass machined part meets your requirements.