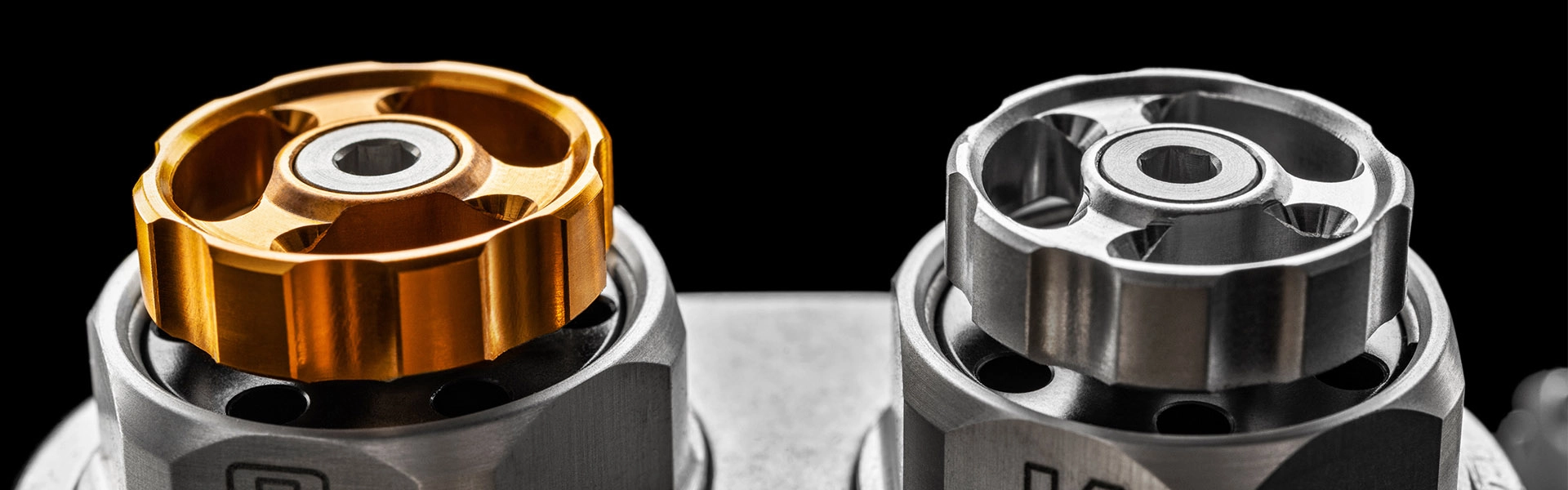

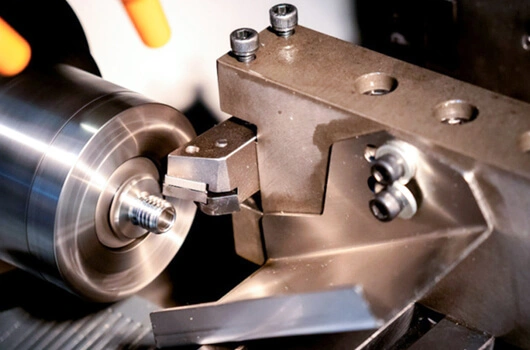

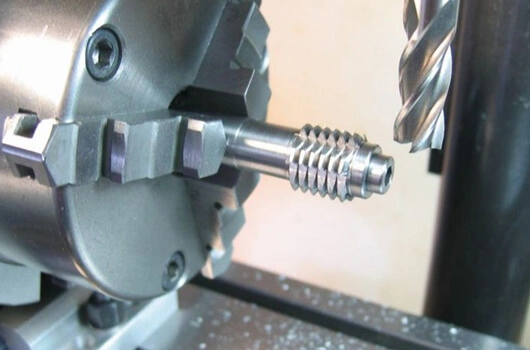

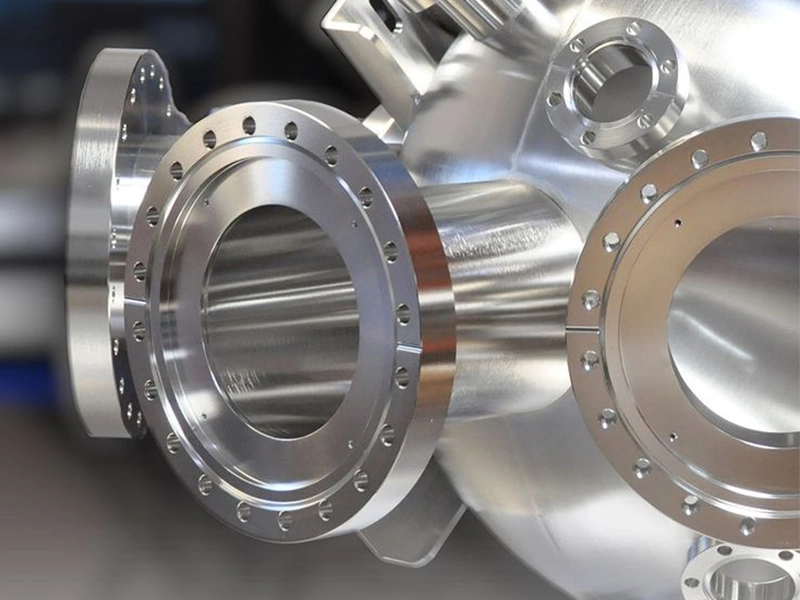

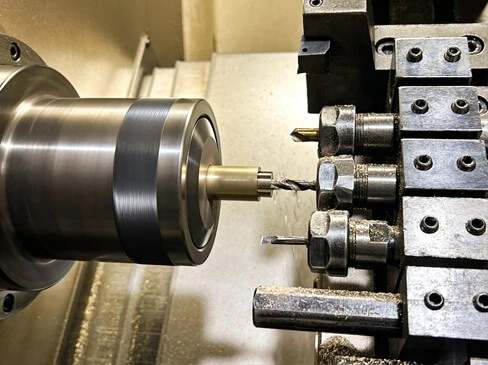

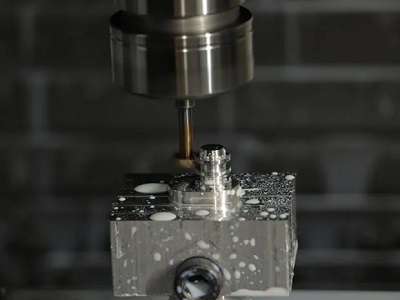

CNC turning is an efficient manufacturing technology that uses computer programs to automatically control machine tools for cutting. It plays a key role in the manufacturing of automobile and motorcycle parts. First, the part shape and tool path are determined through CAD/CAM design, and then the selected material is clamped onto the machine tool. CNC machine tools automatically perform high-precision cutting operations according to predetermined programs to ensure that parts meet design specifications. This technology is not only suitable for mass production and improves efficiency, but can also cope with complex shapes and multi-material machining needs. Overall, CNC turning provides reliable, efficient, and precise manufacturing solutions to the automotive and motorcycle industries. Learn more...

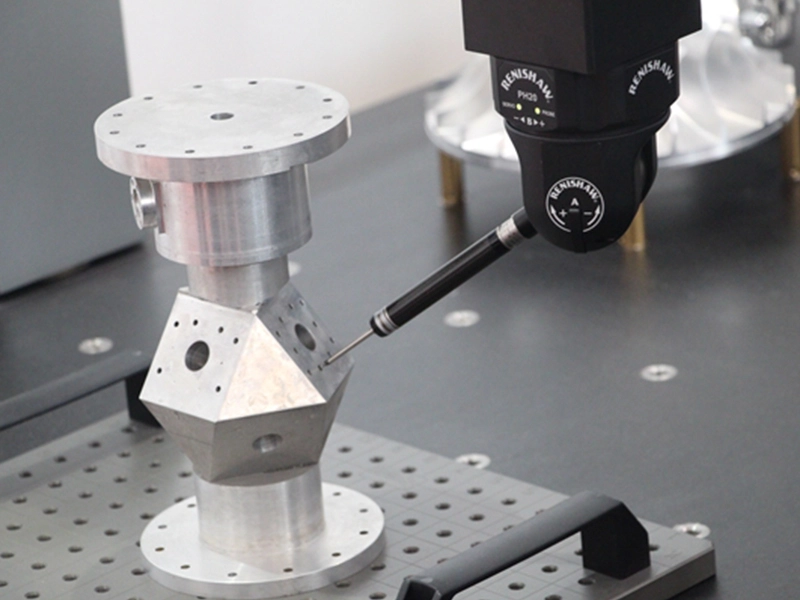

Choosing to use CNC machining to manufacture automobile and motorcycle parts has many advantages. First of all, China CNC machining service is a highly automated manufacturing process that precisely controls tool movement and workpiece cutting through computer programs, ensuring high precision in the manufacturing process. and consistency. This is critical for automotive and motorcycle parts, as they often need to meet strict size and geometry standards.

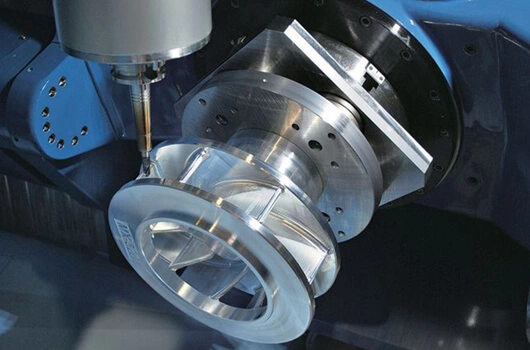

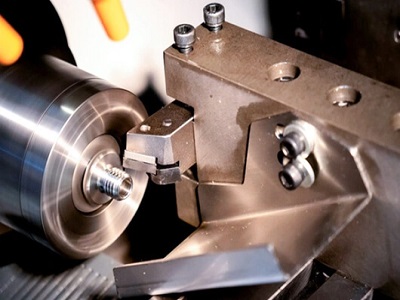

Secondly, the flexibility of CNC machining allows it to adapt to various design needs. Whether it is complex geometry or precise structure, CNC technology can easily handle it, providing engineers and designers with more room for innovation. This is critical to driving technological advancements in the automotive and motorcycle industries.