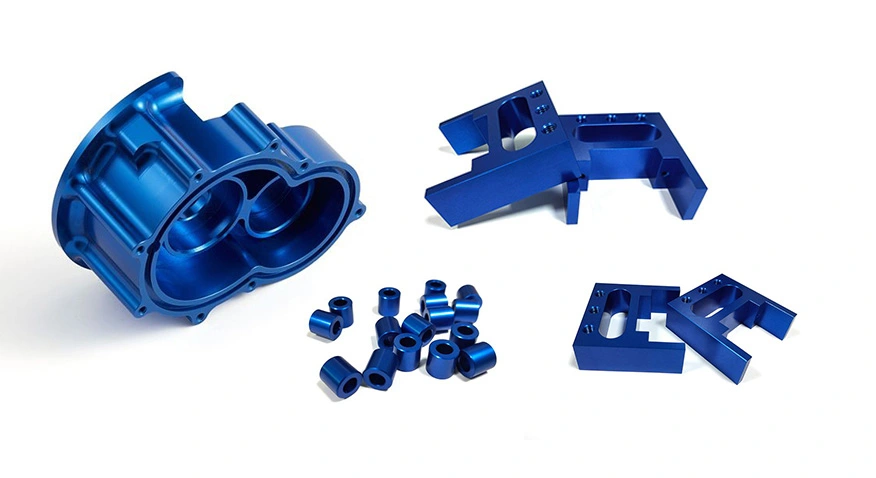

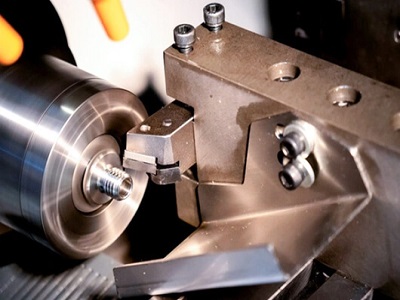

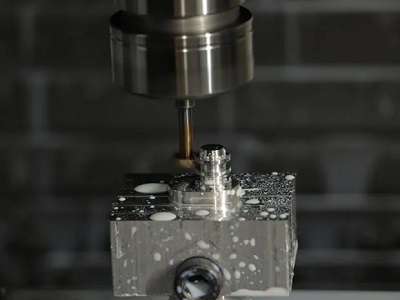

We invest in cutting-edge CNC equipment, boasting over 60 various CNC lathes and multi-axis CNC milling machines. This means we have the capability to handle complex components and perform custom CNC precision machining, ensuring the delivery of outstanding quality.