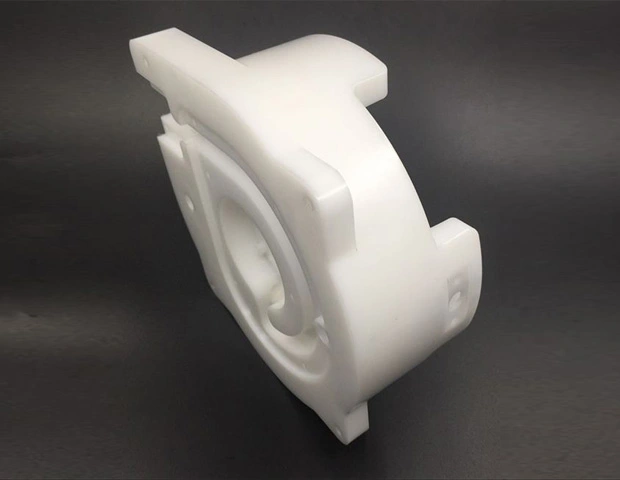

CNC Milling Plastic Parts

Are you looking for a one-stop solution to produce plastic parts with tight tolerances and superior surface finishes?

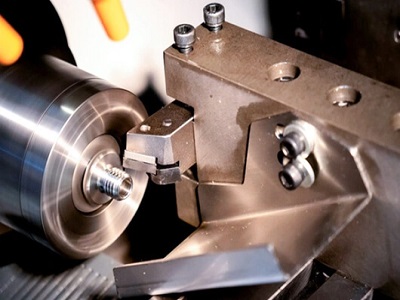

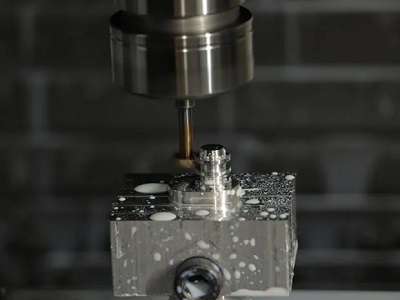

Mingqiang Precision provides leading CNC plastic machining services to ensure excellent quality and fast delivery times. As one of the most proficient custom plastic parts manufacturers with over 50 plastic milling and plastic turning machines, we are able to provide consistently high quality custom plastic parts and stand out at competitive prices.

Therefore, you can easily handle orders for prototypes, as well as CNC production from low to high volumes, covering a wide range of plastic materials. Choose MQJM to provide a reliable manufacturing partner for your project.